Italian research agency fights COVID-19 with smart shelters using biocomposites

SOS Smart Operating Shelter project offers fast-build mobile healthcare structures using natural fiber/biopolymer sandwich panels.

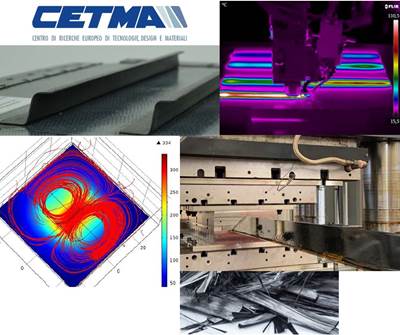

Source | CETMA

Due to the COVID-19 pandemic, the demand for intensive care beds is rapidly increasing worldwide. The SOS - Smart Operating Shelter - project is an important resource, enabling rapid set up of mobile healthcare units for the treatment of infected patients.

The SOS project is led by the Italian research organization CETMA (Brindisi, Italy), which is also a leader in composites research and by RI SpA (Lecce, Italy), a group leader in modular building construction. The project is co-funded by the Apulian Region (Italy) within the INNONETWORK funding measure. A multidisciplinary Apulian partnership is also involved in the project: Politecnico di Bari, ENEA, ENA Consulting, Kinema, Mespo and Protom Group SpA.

As part of the SOS project, architectural layouts were designed and engineering solutions investigated to quickly set up mobile healthcare units that are easy to assemble and install, with smart and low environmental impact sandwich panels. The know-how acquired in this project will be made available to the regional health system.

Eco-composite panels, multifunctional solutions

One of the main objectives of the SOS project is the development of advanced and eco-friendly materials for structural panels that are multifunctional, smart and reconfigurable, ready for use in just a few hours after arrival, without involving specialized personnel for installation. Research and development issues addressed include:

- Innovative sandwich panel inner cores using bio-based polyurethane systems and/or revcycledPET foam;

- Eco-friendly composite laminates for external sandwich panel skins using natural fibers and bio-based polymers;

- Coupling of the core with the outer skins;

- Ability to integrate technical compartments for electrical/IT/medical gases and radiation protection systems;

- Reduction of overall dimensions, study of connection systems for facilitated assembly;

- Pressure-based containment with particular reference to the seals of the movable and extendable elements; conditioning and filtering systems for clinical environment; surfaces and equipment suitable for sanitization; control and maintenance of indoor comfort, even under extreme climatic conditions;

- Operating efficiency of all components, integration of automation solutions, correct operation of each component after each handling and transport;

- Certification of clinical environment per government regulations.

- Acquisition systems, analysis, design, monitoring and interfacing with intelligent decision support and optimized methodologies, in order to ensure compliance with high performance index of all the integrated services deliverable within the complex innovative structure.

In 2019, CETMA developed an innovative bio-based sandwich panel comprising an inner core made from plant-based and/or recycled PET foam, while the outer skins are composite laminates made with natural fibers and polymeric resins obtained from renewable sources.

SOS – three different panel typologies designed for vertical cladding of the shelters. Source | CETMA

In collaboration with the SOS project team, CETMA also devised a technical solution for vertical/horizontal partitions, consisting of three elements: 1-sandwich panel, 2-systems cavity and 3-inner lining panel. Such a solution is very flexible and allows modifying structures for various intended uses.

CETMA is also engaged in the development of multifunctional structures combining:

- Self-supporting structure: sandwich panel application for walls, partitions or ceilings;

- Systems integration: new solutions to more effectively integrate wiring and connections for power supplies, medical gases and data/monitoring systems;

- Smart monitoring: integration of smart environmental sensors and/or electromagnetic (EM) shielding.

Further information is available at www.sos-project.it.

Related Content

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

Read MoreJEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

Read MoreAirborne delivers composite upper stage tank for EU ENVOL project

Nine-member consortium targets development of low-cost, green vertical orbital launcher with manufacture of an ultra-lightweight composite tank design in an automated manufacturing environment.

Read MoreBabyark launches smart, composites-intensive car seat

Impact-absorbing car seat approaches safety holistically with carbon fiber and D3O materials and embedded sensors for real-time monitoring.

Read MoreRead Next

CETMA: composites R&D and innovation in Italy

From design and simulation to inline inspection, induction welding, continuous compression molding and recycled carbon fiber, this lab to support industry is advancing composites in aerospace, automotive, construction and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)