JEC Composites Innovation Award 2022 winners have been announced

The JEC Group has announced the winner for each of the ten Innovation Award categories. Learn more about the winners, their projects and future expectations in person or via livestreaming at JEC World 2022.

Share

On April 26 JEC Group (Paris, France) announced this year’s 10 JEC Composites Innovation Award winners. Don’t miss the opportunity to meet with the winners and learn more about their projects and expectations for the future at JEC World 2022 from May 3-5, 2022. Join them for the Opening session on May 3 at 9:30 in Agora 5 or via livestreaming:

Category: Aerospace (Application)

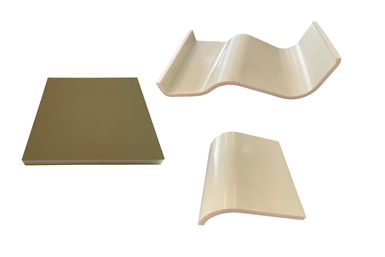

100% thermoplastic panel for cabin interiors

Diab has developed a 100% thermoplastic and recyclable sandwich panel for aerospace cabin interiors to answer current challenges such as sustainability, REACH compliance, production rate increase, etc.

- Diab (Laholm, Sweden)

- Partner(s): Rescoll (Pessac, France), AkzoNobel (Amsterdam, Netherlands) and Roctool SA (Le Bourget du Lac, France)

Category: Aerospace (Process)

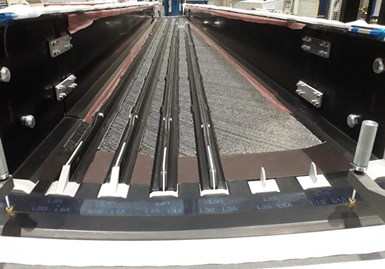

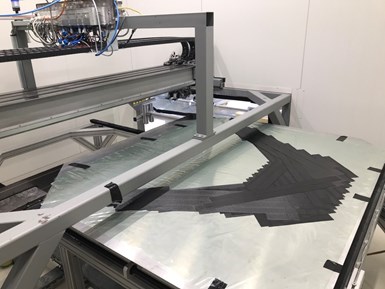

Innovative Infusion Airframe Manufacturing System

Automated out-of-autoclave (OOA) portable manufacturing system for an integrated torsion box of a wing (including skin, stringers, spars and stiffeners in a one-shot part), thus avoiding assembly processes and fasteners.

- MTorres Disenos Industriales S.A.U. (Nevarra, Spain)

- Partner(s): Airbus Defense and Space (Spain)

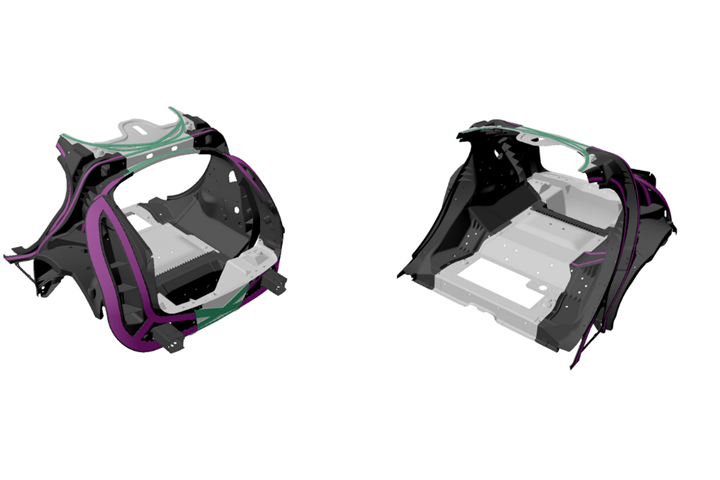

Category: Automotive & Road Transportation (Structural)

TUCANA is an enabler for future battery electric vehicles (BEVs) demonstrated by redesign of the whole rear body structure of a Jaguar I-Pace.

- Jaguar Land Rover (Whitley, U.K.)

- Partners(s): Broetje Automation U.K. Ltd (U.K.), CCP Gransden Ltd. (Belfast, Northern Ireland), Expert Tooling & Automation Ltd. (Coventry, U.K.), Toray International U.K. Ltd. (London), University of Warwick (U.K.) and CFMS Ltd. (Bristol, U.K.)

Category: Automotive & Road Transportation (Surfaces)

Seamless Integration of Flexible Solar Film in FRP

Seamless integration of flexible solar film in automotive fiber-reinforced plastic (FRP) components (roof top, hood, etc.) for high-volume application, using a high-pressure resin transfer molding (HP-RTM) process.

- Audi AG (Zwickau, Germany)

- Partner(s): Mubea Carbo Tech GmbH (Salzburg, Austria) and Apollo Power Ltd. (Yokneam Elit, Israel)

Category: Building & Civil Engineering

Structural Re-Use of Thermoset Composites

The innovative methodology of structural re-use of thermoset composites enables end-of-life (EOL) thermoset composites to be re-used in new products. It is a circular solution for these materials.

- Windesheim (Netherlands)

Category: Design, Furniture & Home

Kairlin: A New Recyclable and Compostable Material

Photo Credit: Kairos

Kairlin is a recyclable and compostable biomaterial, allowing point-of-sale and signage displays to be produced and recycled with low environmental impact, in line with the circular economy approach.

- Kairos (Paris, France)

- Partners(s): Eco-Technilin, University of South Brittany (France) and the University of Portsmouth (U.K.)

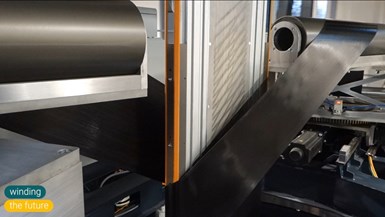

Category: Equipment & Machinery

Winding the Future – Fibraforce Technology

Fibraforce technology: Revolutionizing the high-volume production of genuine customized multi-axial thermoplastic cross-ply laminates with a continuous and ultra-fast winding process.

- Fibraworks GmbH (Roetgen, Germany)

- Partners(s): Hille Engineering GmbH & Co. KG (Roetgen, Germany), SEM GmbH (Ludwigshafen, Germany) Quality Automation GmbH (Stolberg, Germany) and Fibraforce AG (Basel, Switzerland)

Category: Maritime Transportation & Shipbuilding

Marine Rotor Blades Made of Voith “Carbon4Stack”

Voith Inline Thruster CFRP rotor blades are made using Voith’s prepreg stacks (Carbon4Stack) laminate to provide ultimate vessel maneuverability to the marine industry.

- Voith Composites SE & Co. KG (Garching bei München, Germany)

- Partners(s): J.M. Voith SE & Co. KG | VTA (Heidenhaim, Germany), Gurit (U.K.) and Cotesa GmbH (Mittweida, Germany)

Category: Renewable Energy

RecyclableBlade

Photo Credit: Siemens Gamesa

Siemens Gamesa, in partnership with Aditya Birla Advanced Materials, has designed, manufactured and are ready to install what is said will be the first offshore wind turbine blades that can be easily dissolved and recycled.

- Siemens Gamesa Renewable Energy (SGRE, Brande, Denmark)

- Partners(s): Aditya Birla Advanced Materials (Bangkok, India)

Category: Sports, Leisure & Recreation

Race-Ready Bond Between Thermoset and Thermoplastic Biocomposites

Said to be the first, ready-to-market product which unites motorsport-proven natural fiber composite materials and road-focused bio-based thermoplastics with a reversible and recycling-ready connection technology.

- Bcomp Ltd. (Fribourg, Switzerland)

- Partners(s): KTM Technologies GmbH (Salzburg, Austria) Mitsubishi Chemical Advanced Materials GmbH (Sinsheim, Germany), Alba Tooling & Engineering GmbH (Forstau, Austria) and Altendorfer Kunststofftechnik GmbH (Neureichenau, Germany)

Read Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More