McNAIR Aerospace Center installs Heraeus Noblelight humm3 technology

Composites heating technology will comprise of a fully integrated system with a plug-and-play head module to further extend AFP and cylinder production capabilities.

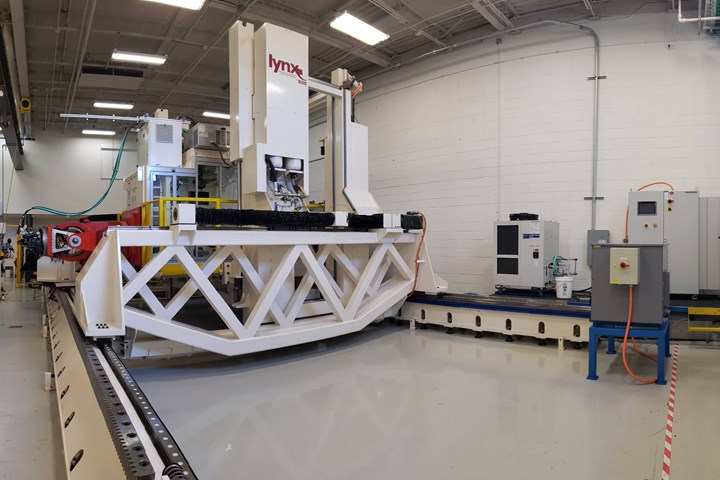

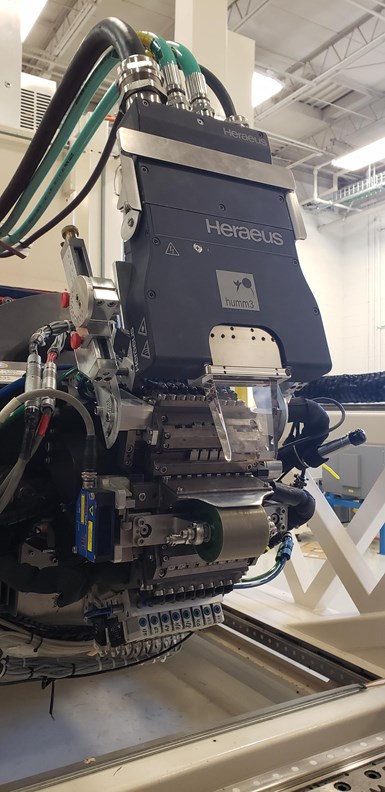

humm3 on gantry at the McNAIR Center. All photo credit: McNAIR Aerospace Center.

Heraeus Noblelight Ltd. (Cambridge, U.K.), a flash systems technology company, has recently confirmed the installation of its latest humm3 system to the McNAIR Aerospace Center based at the University of South Carolina (Columbia). This system, which offers a flexible, controllable heat solution for automated fiber placement (AFP), automated tape laying (ATL), filament winding and other composites applications, represents a significant upgrade to the humm3 discovery system the McNair team have been working with.

The newest installation of the humm3 system will comprise of a powerful, fully integrated system with a plug-and-play head module. The system is being integrated onto the Ingersoll Machine Tools Lynx AFP cell and will allow the team to further extend their AFP and cylinder production capabilities.

“We are delighted that the McNair Center have selected humm3 technology to further explore the capabilities of composites heating technology,” says Peter Lascelles, senior sales manager for Heraeus Noblelight. “The McNair Center are experienced users of humm3 technology, having had a discovery system for some years now. We look forward to seeing the results they achieve with this even more capable product.”

The McNair Center for Aerospace Innovation and Research reports that it has a mission to “grow South Carolina’s knowledge based economy and support industry through aerospace education, research leadership and industry advancement.” Keeping composites technology at the heart of its four thrust areas detailed in its mission statement will enable the Center to bridge the gap between technology and industry.

“We at the McNair Center are excited to partner with Heraeus in upgrading our equipment to have the latest in humm3 technology,” says McNAIR Center Director, Dr. Abdel Bayoumi. “This upgrade will allow us to continue our activities in advancing composite manufacturing while also paving the way for new research opportunities.”

Heraeus Noblelight further notes that the technology has recently introduced two new product families, including humm3 discovery which is ideally suited to research and development and humm3 enterprise which is intended for integration and industrial work.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

Airbus video highlights RACER compound helicopter first flight

Launched as part of a Clean Sky 2 program, a compound design — rotor, split fixed-wing, propulsive propellers — uses composites to cut fuel consumption and emissions by 20%.