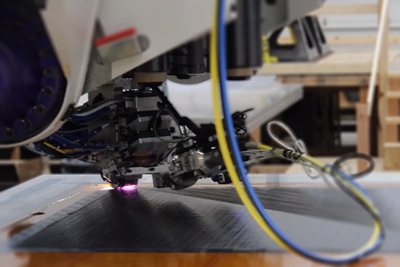

NCC unveils AFP/ATL dual system for large, complex structures

The hybrid cell, created in partnership with Electroimpact, can be used individually or together for automated composite manufacturing at a medium- to large-scale level.

Photo Credit: NCC

Celebrating its 10-year anniversary, U.K. composites research and development facility, the National Composites Centre (Bristol), recently unveiled its latest state-of-the-art capabilities in the form of a new automated fiber placement/automated tape laying (AFP-ATL) cell. According to the NCC, the new cell is the final piece in a £36.7 million investment, including ten new fully digital automated composite manufacturing capabilities that have been installed at the facility in the past 18 months.

The cell, created in partnership with Electroimpact (Flintshire, U.K.) combines both AFP and ATL in a single system. The dual system can reportedly be used individually or together to collaborate and create large, complex structures with minimal downtime. The robot is intended for medium- to large-scale manufacturing with high performance and accuracy robotic motion platform.

The AFP process head applies eight 12.7-millimeter-width tows with either an infrared heater to manufacture thermoset composites, or the novel humm3 flash technology developed by Heraeus Noblelight Ltd. (Cambridge, U.K.). The humm3 technology has additionall been tested at the NCC for the manufacture of low-temperature thermosets (30-60ºC) and high-temperature thermoplastics or bindered dry fiber (100-300ºC).

Similarly, the NCC say the ATL head can deposit tapes of 75-, 200- or 300-millimeter widths using the same heating systems and material processing capability as AFP.

Through collaboration, the NCC believe that AFP-ATL has the ability to reduce the barrier to entry to these game-changing technologies and expand the composite market into other areas such as renewable energy, oil and gas, construction and rail.

“The NCC’s AFP-ATL capability is a perfect test bed for automated composite manufacturing at a medium- to large-scale level,” says Eva Collado Sastre from the NCC. “The system will enable new and existing markets to build up their innovation platforms from the ground up, from small-scale prototyping and material testing through to full-scale demonstrators and data analytics. The output for customers will be the enabling of high-performance products, created at high volume with reduced cost and waste to achieve step change technology in their field.”

Vertical and horizontal rotators enable the use of complex tools to create geometries such as convex and concave panels, large-scale diameter pipes, spars or barrel/tower structures, the NCC notes. The rotators enable components of up to 4.6 meters in diameter, and seven meters in length to be manufactured. Further, the cell’s flat tables also allow for smaller scale analyses such as material testing or prototype trials to de-risk programs and build knowledge prior to larger scale projects.

Alastair Gray from Electroimpact adds: ”The hybrid cell offers the NCC flexibility to manufacture a range of part geometries and using various material types and formats. Furthermore, thanks to the modular nature of the end effectors to the motion platform, it is possible for the NCC to future proof their cell to accommodate the very latest in composite head technology and innovation as it becomes available, thus ensuring NCC is able to offer cutting-edge technology to customers and stake holders alike.”

According to Alex Hickson from the Aerospace Technology Institute (ATI, Cranfield, U.K.), this new investment will continue to enhance the U.K.’s position in leading aerospace composite research, development and manufacturing capabilities. “This advanced combined AFP-ATL automation equipment offers a means to develop and broad selection of future products for aircraft structures and engine applications,” Hickson notes. “It has been specified to meet the sector’s demanding technical and quality requirements at increasingly high rates to meet the productivity needs of industry that are commercially competitive.”

The NCC is one of seven centers that make up the U.K.’s High Value Manufacturing Catapult which is Europe’s largest RTO. Opened in 2011, the center has reportedly seen more than £200 million in investment capabilities. It has worked with organizations globally to progress the adoption of composite products.

The innovations provided by AFP and ATL have transformed the aerospace industry, the NCC says, allowing fuselage sections and wing spars to be manufactured at an industrial scale, not previously possible using traditional composite manufacturing methods. Currently though, these breakthroughs have been almost exclusively benefitted the traditional composites manufacturing industries mentioned. Through collaboration, the NCC believe that AFP-ATL has the ability to reduce the barrier to entry to these game-changing technologies and expand the composite market into other areas such as renewable energy, oil and gas, construction and rail.

The ten automated composite manufacturing capabilities that have been installed in the past 18 months thanks to funding from ATI and West of England Combined Authority (WECA, Bristol, U.K.) Local Enterprise Partnerships also include:

- An ultra-high-rate deposition cell that can lay up to 5 x 20-meter-wide components with millimeter accuracy. Includes a 20-meter multi zoned oven and a state-of-the-art verification cell to accompany the scale.

- Said to be Europe’s largest multi axial composite braider and;

- A composite overmolder which is of particular interest to automotive and other high-rate manufacturing sectors.

Related Content

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

Victrex, Electroimpact achieve thermoset AFP speeds using thermoplastics

Using Electroimpact’s AFP technology and Victrex’s low-melt PAEK prepreg tape, the companies report laydown speeds of 4,000 inches per minute.

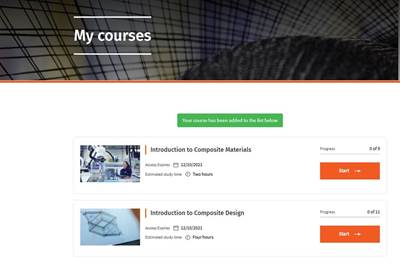

Read MoreNCC launches new online composites training platform

Suite of affordable introductory and practical and theory based, in-person courses taught by composites experts available to users at any location and organization.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More