Modec, Toray jointly develop FPSO, FSO repair solution using CFRP patches

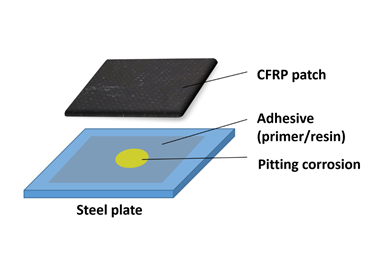

CFRP patch technology will target localized pitting corrosion repairs for floating vessels used by the oil and gas industry, leading to minimal disruption and more streamlined repair.

Modec Inc. (Tokyo, Japan) and Toray Industries Inc. (Tokyo) have jointly developed a carbon fiber-reinforced plastic (CFRP) patch technique for repairs on floating production, storage and offloading (FPSO), and floating storage and offloading (FSO) systems.

FPSO and FSO repair services provided by Modec, a general contractor specializing in engineering, construction, operation and maintenance services of offshore oil and gas vessels, will use this CFRP patch technique for pitting corrosion repair beginning in 2024. The American Bureau of Shipping (ABS), which provides classification services for marine and offshore assets, approved this technique for repairing areas up to 300 millimeters in diameter that have suffered damage from pitting corrosion.

According to the companies, FPSO and FSO maintenance takes place without interruption to oil and gas production. Accordingly, developing a repair technique that facilitates the efficient deployment of materials and equipment offshore and does not involve hot work is vital. These considerations prompted Modec and Toray to jointly develop a vacuum-assisted resin transfer molding (VARTM) process for CFRP repairs in 2020. ABS approved applying CFRP to steel to restore its mechanical strength.

While ideal for repairing large corrosion areas, this process was less suitable for pitting corrosion repairs. It only requires bonding prefabricated CFRP patch flat plates over pitting corrosion, reportedly reducing the workforce by half and improving lead times (referring to on-site time compared with the VARTM process and excluding materials procurement lead times).

This technique eliminates the need for vacuum pumps and other equipment and streamlines the process of transporting reinforcement materials and construction tools onboard. Moreover, it ensures minimal disruption in oil and gas production because it eliminated the need for hot work.

Together with Toray, Modec will cater to the diverse corrosion repair needs of FPSO and FSO operators by offering the in-situ VARTM solution for extensive repairs and the CFRP patch technology for localized repairs. The two companies will continue to develop repair technologies for these vessels to promptly address market needs while tackling environmental and other social issues to contribute to a sustainable economy.

Related Content

-

Segula Technologies initiates Z-WasTEK project for composite recycling, repair

The combined use of 3R resin and the development of digital programs will target the repair and more responsible use of carbon fiber.

-

CompPair adapts HealTech composites to LCM processes

The new system, demonstrated through the manufacture of a large-scale wind turbine blade section, enables the repair and recovery of infused composite structures within minutes.

-

Determining steel/composite failure load of bonded repair assemblies

Bureau Veritas and partners use a novel equivalent interface test specimen and simulation to predict failure load in bonded composite patch repairs to steel structures.