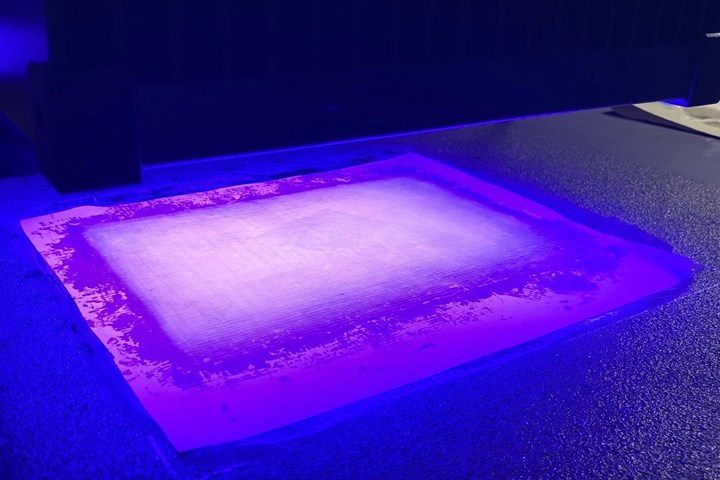

UV-cure prepreg patch repair

Even though the carbon fiber/epoxy prepreg repair that Custom Technologies LLC developed for infield composite bridges was demonstrated to be simple and quick, a more expedient system was developed using glass fiber-reinforced UV-cure vinyl ester resin prepreg. Photo Credit: Custom Technologies LLC

Modular deployable bridges are a key asset in military tactical operations and logistics, as well as for restoring transportation infrastructure during natural disasters. Composite construction is being investigated to reduce the weight of such bridges, which in turn reduces the burden on transport vehicles and launch-retrieval mechanisms. Composites also offer the potential to increase load-carrying capability and extend service life compared to metal bridges.

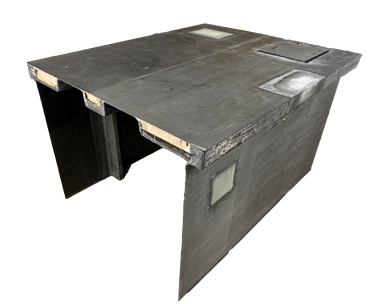

The Advanced Modular Composite Bridge (AMCB) is one example, designed and built using carbon fiber-reinforced epoxy laminates (Fig. 1) by Seemann Composites LLC (Gulfport, Miss., U.S.) and Materials Sciences LLC (Horsham, Penn., U.S.). However, the ability to repair such structures in the field has been an issue hindering the adoption of composites.

Fig. 1 Composite bridges, key infield assets

The Advanced Modular Composite Bridge (AMCB) was designed and built by Seemann Composites LLC and Materials Sciences LLC using carbon fiber-reinforced epoxy composites. Photo Credit: Seeman Composites LLC (left) and U.S. Army (right).

In 2016, Custom Technologies LLC (Millersville, Md., U.S.) was awarded a Small Business Innovation Research (SBIR) Phase I grant funded by the U.S. Army to develop a repair method that can be performed successfully by soldiers in the field. Based on this method, a Phase II SBIR grant was awarded in 2018 to demonstrate new materials and battery-operated equipment that could restore 90% or more of the structure’s original strength, even when the patch repair is performed by a novice with no prior training. The feasibility of the technology was established by performing a series of analytical, material selection, test specimen fabrication and mechanical testing tasks, as well as small- and full-scale repairs.

From cracked ship decks to bridge decks

The principal investigator for both SBIR phases was Michael Bergen, founder and president of Custom Technologies LLC. Bergen retired from Naval Surface Warfare Center (NSWC) Carderock with a 27-year tenure in the Structures and Materials Department, where he managed the development and application of composite technologies for the U.S. Navy fleet. Dr. Roger Crane joined Custom Technologies in 2015 after retiring from the U.S. Navy in 2011 with 32 years of service. His composites expertise includes technical publications and patents covering topics such as new composite materials, prototype manufacturing, joining methods, multifunctional composites, structural health monitoring and composite repair.

These two experts had already developed a unique process that used composites to repair cracking in 5456 aluminum superstructures on the USS Ticonderoga CG-47 class guided-missile cruiser. “That process was developed to reduce crack growth and serve as an affordable alternative to a $2-4 million deck plate replacement,” says Bergen. “Thus, we had demonstrated that we knew how to do repairs outside of the lab and in a real service environment. But the challenge was that current methods for military assets are not very successful. The options are a bonded doubler repair [essentially gluing a plate on top of the damaged area] or remove the asset from service for depot level (D-level) repairs. There are so many assets sitting off to the side because a D-level repair is required.”

What is needed, he continues, “is a method that can be executed by a soldier with no experience in composites, using only a kit and repair manual. Our goal was to make the process easy: Read the manual, assess the damage and do the repair. We didn’t want any mixing of liquid resins because that requires precise measuring to ensure full cure. We also needed a system with no HAZMAT waste to handle after the repair is completed. And it had to be packaged as kits that can be deployed by the networks already in place.”

Novel bonded patch materials

One solution that Custom Technologies has successfully demonstrated is a portable kit that enables a bonded composite patch, tailored to the size of the damage — up to a maximum of 12 square inches — using a toughened epoxy adhesive. Demonstrations were completed on composites representative of the 3-inch-thick AMCB deck, which features a 3-inch-thick balsa core (15 pounds per cubic foot density) with faceskins comprising two plies of Vectorply Corp. (Phenix City, Ala., U.S.) C-LT 1100 carbon 0°/90° biaxial stitched fabric, one ply of C-TLX 1900 carbon fiber 0°/+45°/-45° triaxial and two more plies of C-LT 1100 for five plies total. “We decided the kit would use premade patches in a quasi-isotropic layup of similar multiaxials so that fabric orientation wouldn’t be an issue,” says Crane.

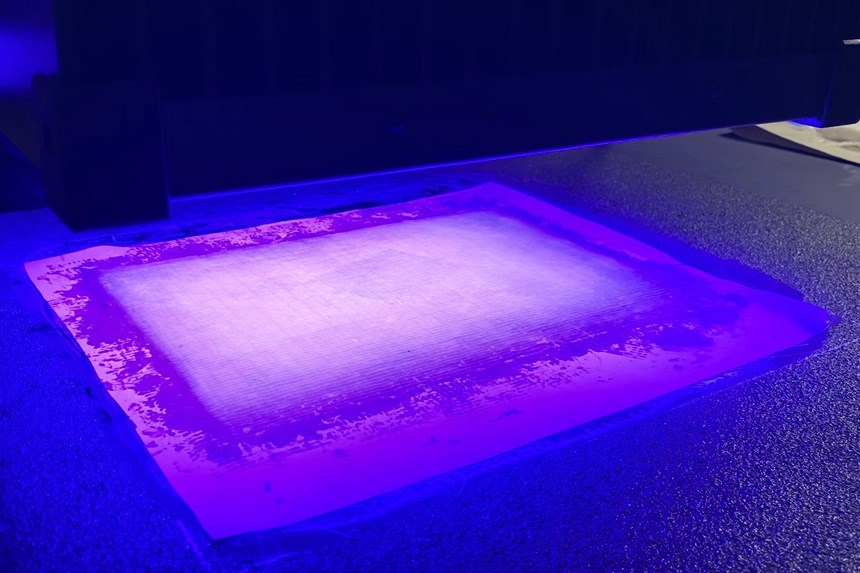

The next issue was the resin matrix for laminating repairs. To avoid mixing liquid resins, the patch would use prepregs. “However, the challenge for these is storage,” explains Bergen. To develop a storable patch solution, Custom Technologies teamed with Sunrez Corp. (El Cajon, Calif., U.S.) to develop a glass fiber/vinyl ester prepreg that cures in six minutes using ultraviolet (UV) light. It also worked with Gougeon Brothers (Bay City, Mich., U.S.), which suggested using a novel flexible epoxy resin film.

Early investigations had already demonstrated that epoxy was the most suitable resin for a carbon fiber prepreg — UV-cure vinyl ester works great with translucent glass fibers but does not cure beneath light-blocking carbon fibers. Based on Gougeon Brothers’ novel film, the final epoxy prepreg demonstrated a one-hour cure at 210°F/99°C with a long shelf life at room temperature — no low-temperature storage is required. The resin will also cure at higher temperatures, says Bergen, for example at 350°F/177°C if a higher glass transition temperature (Tg) is required. Both prepregs are supplied in the portable repair kit as premade prepreg patch layups sealed in plastic film envelopes.

Because repair kits may be in storage for an extended time, Custom Technologies was required to perform a shelf-life study. “We bought four hard plastic cases — typical of the type the military uses for shipping equipment — and put samples of the epoxy adhesives and vinyl ester prepreg in each one,” says Bergen. The cases were then placed in four different locations for testing: on the roof of Gougeon Brothers’ facility in Michigan, on the roof of an airport in Maryland, outdoors at a facility in Yucca Valley (California desert) and at an outdoor corrosion testing lab in southern Florida. All of the cases had data loggers, Bergen notes, “and we’d pull data and material samples every three months for evaluation. A maximum temperature of 140°F was recorded by the boxes in Florida and California, which is a real challenge for most repair resins.” In addition, Gougeon Brothers tested the newly developed neat epoxy resin in-house. “Samples held for months in an oven at 120°F started to polymerize,” says Bergen. “However, for corresponding samples held at 110°F, the resin chemistry advanced only a small amount.”

Repairs were validated on test panels as well as this scaled model of the AMCB, which used the same laminate and core materials as in the original bridge built by Seemann Composites. Photo Credit: Custom Technologies LLC

Repair testing

To demonstrate the repair technology, representative laminates had to be manufactured, damaged and then repaired. “In the Phase I project, we initially worked with small-scale, 4 x 48-inch beams and four-point bending tests to assess the viability of our repair process,” says Crane. “We then transitioned to 12 x 48-inch panels in the Phase II project, applying load to create a biaxial stress state to failure, and then evaluated the repair performance. In the Phase II project, we also completed repairs to a model of the AMCB we had built.”

The test panels used to demonstrate the repair performance were fabricated using the same pedigree in laminate and core as the AMCB built by Seemann Composites, says Bergen, “but we scaled down the facesheet thickness from 0.375 inch to 0.175 inch, based on the parallel axes theorem. This approach, along with additional elements of beam theory and classical laminate theory [CLT], was used to relate the moment of inertia and effective stiffness of the full-scale AMCB to more tractable and cost-efficient down-sized demonstrative articles. We then used finite element analysis [FEA] models developed by XCraft Inc. (Boston, Mass., US) to refine the design of the structural repairs.” Carbon fiber fabrics for the test panels and AMCB model were purchased from Vectorply and balsa core was supplied by Core Composites (Bristol, R.I., U.S.).

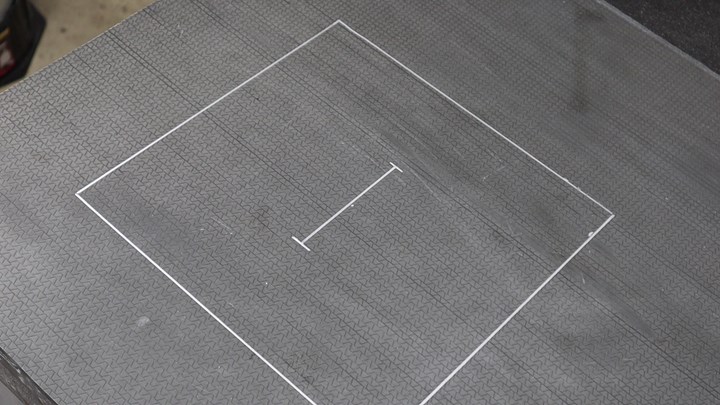

Step 1. This test panel shows the 3-inch hole diameter to simulate damage marked at center as well as the repair perimeter. Photo credit for all steps: Custom Technologies LLC.

Step 2. A battery-powered hand grinder is used to remove damaged material and scarf a 12:1 taper to receive the repair patch.

“We wanted to simulate a higher degree of damage in the test panels than what is likely to be seen on in-field bridge decks,” Bergen explains. “So, our approach was to use a hole saw to make a 3-inch-diameter hole. We then pulled the plug of damaged material out and performed a 12:1 scarf using a handheld pneumatic grinder.”

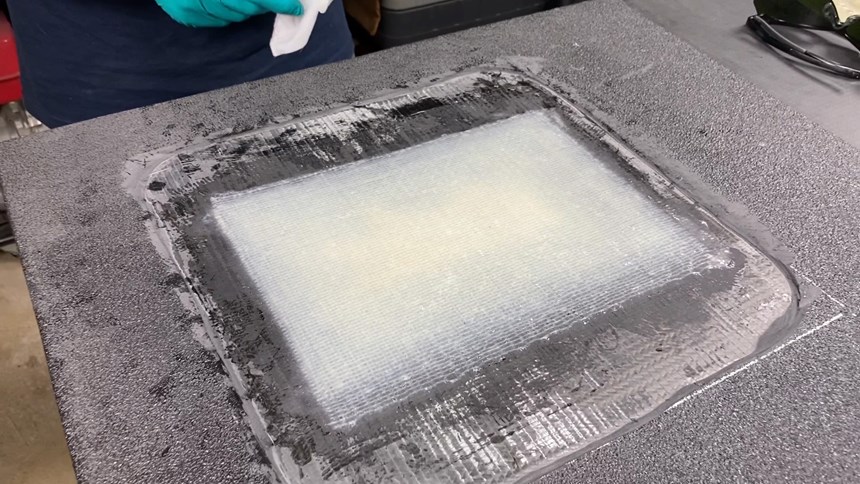

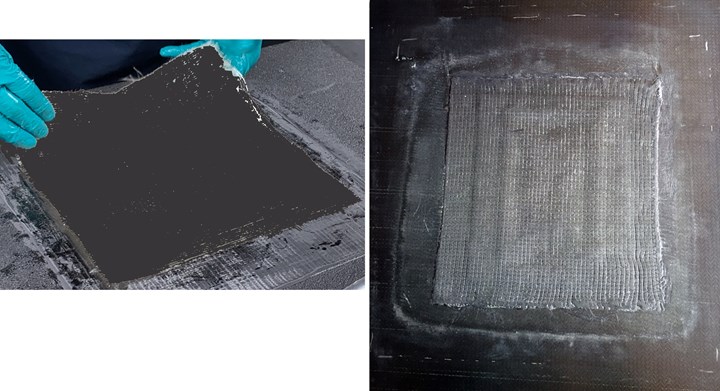

For the carbon fiber/epoxy repair, explains Crane, once the “damaged” facesheet material was removed and the appropriate scarf applied, the prepreg was cut to width and length to match the taper of the damaged area. “For our test panels, this required four plies of prepreg that brought the repair material to be even with the top of the original undamaged carbon facesheet. After this, three overplies of the carbon/epoxy prepreg were centered over this repair section. Each successive ply extended 1 inch on all sides of the ply below, which provided a gradual load transfer from the “good” surrounding material into the repaired area.” The total time to perform this repair — including repair area preparation, cutting and placing the repair material and applying the cure procedure — was approximately 2.5 hours.

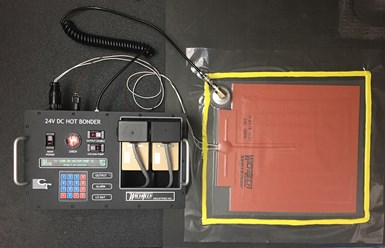

For the carbon fiber/epoxy prepreg, the repair area was vacuum bagged and cured using a battery-operated hot bonder for one hour at 210°F/99°C.

Even though the carbon/epoxy repair is simple and quick, the team recognized the need for an even more expedient solution that could restore performance. This led to the exploration of the ultraviolet (UV) cured prepreg. “Interest in Sunrez vinyl ester resin was based on previous Navy experience with Mark Livesay, who founded the company,” Bergen explains. “We began by providing Sunrez with a quasi-isotropic glass fabric to prepreg with their vinyl ester and evaluated the cure profile under varied conditions. Further, knowing that vinyl ester resin does not provide as suitable secondary bonding properties as epoxy does, there was an additional effort to evaluate various bondline coupling agents and qualify one for this application.”

Another issue was that glass fiber does not provide the same mechanical properties as carbon fiber. “This was addressed by using one additional ply of the glass/vinyl ester compared to the carbon/epoxy patch,” says Crane. “The reason only a single additional layer was required was that the glass material was a heavier fabric.” This resulted in a suitable patch that could be applied and then cured in six minutes even in very cold/freezing infield temperatures with no need to provide heat. Crane notes this repair could be completed in one hour.

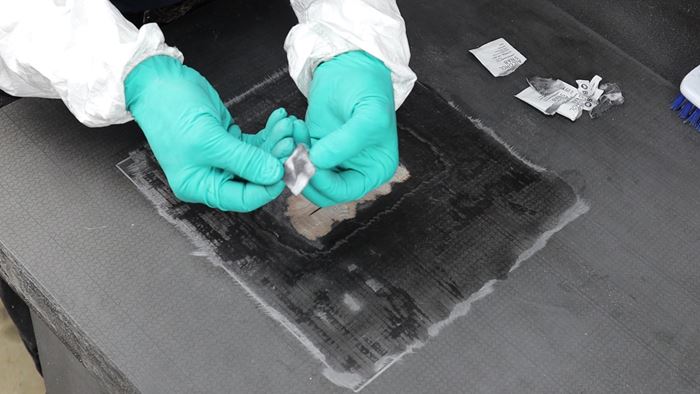

Both patch systems were demonstrated and tested. For each repair, the area to be damaged was marked (step 1), created with the hole saw and then removed using a battery-powered hand grinder (step 2). The repair area was then scarfed to a 12:1 taper. The scarfed surface was cleaned with alcohol pads (step 3). Next, the repair patch was cut to size, positioned on the cleaned surface (step 4) and consolidated with a roller to remove air bubbles. For the glass fiber/UV-cure vinyl ester prepreg, a peel ply was then placed over the repair area and the patch was cured using a cordless UV light for six minutes (step 5). For the carbon fiber/epoxy prepreg, the repair area was vacuum bagged and cured using a pre-programmed, one-button, battery-operated hot bonder for one hour at 210°F/99°C.

Repair steps

“We then performed tests to evaluate the adhesive bond of the patch and ability to restore the structure’s load-carrying capability,” says Bergen. “In Phase 1, we were required to demonstrate ease of application and ability to restore at least 75% strength. This was accomplished on the 4 x 48-inch carbon fiber/epoxy and balsa core beams in four-point bending following the repair of simulated damage. The Phase 2 project used 12 x 48-inch panels and had to show greater than 90% strength requirement under complex strain loading. We met all of these requirements and then filmed the repair methods on the AMCB model to provide a visual reference for how to use the infield techniques and equipment.”

Novice success, future applications

One key aspect of the project was to prove that a novice could easily complete the repair. To do this, Bergen had an idea: “I had promised a demonstration to our two technical points of contact at the Army: Dr. Bernard Sia and Ashley Genna. At final review for the Phase I project, I asked Ashley, who had no prior repair experience, to perform the repair. Using the kits and manual we provided, she applied the patch and completed the repair without any issues.”

Fig. 2 Battery-powered cure

A pre-programmed, battery-powered hot bonder cured the carbon fiber/epoxy repair patches with the push of one button, no repair knowledge or cure cycle programming required. Photo Credit: Custom Technologies, LLC

Another key development is the battery-powered curing system (Fig. 2). “With infield repair, you only have battery power,” notes Bergen. “All of the process equipment in our developed repair kit is cordless.” This includes the battery-powered hot bonder that Custom Technologies developed with hot bonder supplier WichiTech Industries Inc. (Randallstown, Md., U.S.). “This battery-powered heat bonder is pre-programmed to complete the cure, so the novice doesn’t need to program for the cure cycle,” says Crane. “They simply push the button and it completes the appropriate ramp and soak.” The batteries currently used last one year before they need to be recharged.

With the Phase II project now completed, Custom Technologies is preparing a follow-on enhancement proposal and collecting letters of interest and support. “Our goal is to mature this technology to TRL 8 and get it out into the field,” says Bergen. “We also see potential for non-military applications.”

Related Content

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Aircraft composites repair moves toward maturity

New technologies seek to address the challenges MROs will increasingly face in the age of commercial airliners with composite airframes.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More