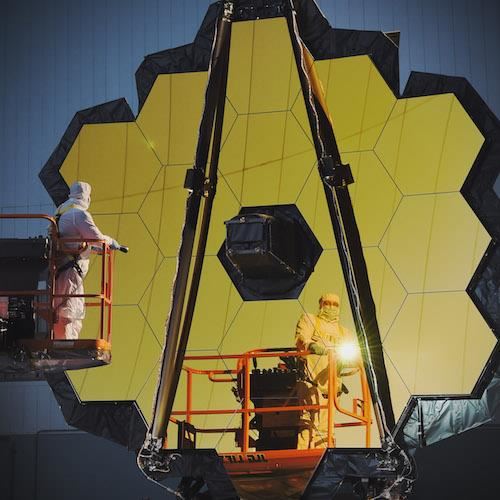

NASA completes Center of Curvature test on the James Webb Space Telescope

Engineers and technicians working on the James Webb Space Telescope successfully completed the first important optical measurement of Webb’s fully assembled primary mirror.

The James Webb Space Telescope, the most powerful space telescope ever built, just completed an important milestone: the first important optical measurement of Webb’s fully assembled primary mirror, called a Center of Curvature test. The mirror consists of 18 primary mirror segments, each 1.3m wide and mounted on a composite backplane structure.

NASA says that taking a “before” optical measurement of the telescope’s deployed mirror is crucial before the telescope goes into several stages of rigorous mechanical testing. These tests will simulate the violent sound and vibration environments the telescope will experience inside its rocket on its way out into space. This environment is one of the most stressful structurally and could alter the shape and alignment of Webb’s primary mirror, which could degrade or, in the worst case, ruin its performance.

Webb has been designed and constructed to withstand its launch environment, but it must be tested to verify that it will indeed survive and not change in any unexpected way. Making the same optical measurements both before and after simulated launch environment testing and comparing the results is fundamental to Webb’s development, assuring that it will work in space.

“This is the only test of the entire mirror where we can use the same equipment during a before and after test,” says Ritva Keski-Kuha, the test lead and NASA’s Deputy Telescope Manager for Webb at NASA's Goddard Space Flight Center. “This test will show if there are any changes or damages to the optical system.”

In order to conduct the test, optical engineers set up an interferometer, the main device used to measure the shape of Webb’s mirror. Waves of visible light are less than a thousandth of a millimeter long, and optics like Webb’s need to be shaped and aligned even more accurately than this to work correctly. Making measurements of the mirror shape and position by lasers prevents physical contact and damage (scratches to the mirror). So scientists use wavelengths of light to make tiny measurements. By measuring light reflected off the optics using an interferometer, they are able to measure extremely small changes in shape or position. An interferometer gets its name from the process of recording and measuring the ripple patterns that result when different beams of light mix and their waves combine or ‘interfere.’

During the test conducted by a team from NASA Goddard, Ball Aerospace of Boulder, Colorado, and the Space Telescope Science Institute in Baltimore, temperature and humidity conditions in the cleanroom were kept incredibly stable to minimize drift in the sensitive optical measurements over time. Even so, tiny vibrations are ever-present in the cleanroom that cause jitter during measurements, so the interferometer is a ‘high-speed’ one, taking 5,000 ‘frames’ every second, which is a faster rate than the background vibrations themselves. This allows engineers to subtract out jitter and get good, clean results.

The Center of Curvature test measures the shape of Webb’s main mirror by comparing light reflected off of it with light from a computer-generated hologram that represents what Webb’s mirror ideally should be. By interfering the beam of light from Webb with the beam from the hologram reference, the interferometer accurately compares the two by measuring the difference to incredible precision. “Interferometry using a computer-generated hologram is a classic modern optical test used to measure mirrors,” says Keski-Kuha.

With the largest mirror of any space telescope, taking this measurement is a challenge. “We have spent the last four years preparing for this test,” says David Chaney, Webb’s primary mirror metrology lead at Goddard. “The challenges of this test include the large size of the primary mirror, the long radius of curvature, and the background noise. Our test is so sensitive we can measure the vibrations of the mirrors due to people talking in the room.”

After the measurements come back from the interferometer the team will analyze the data to make sure the mirrors are aligned perfectly before the launch environment tests. The Center of Curvature test will be repeated after the launch environment testing and the results compared to confirm that Webb’s optics will work after their launch into space.

The Webb telescope will provide images of the first galaxies ever formed, and explore planets around distant stars. It is a joint project of NASA, the European Space Agency and the Canadian Space Agency. The telescope will be launched in 2018.

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)