Natilus announces Horizon blended wing body CFRP aircraft for 200-passenger narrowbody market

Following its Kona cargo aircraft with 460 pre-orders, this larger all-CFRP model responds to airlines’ request to fill Boeing and Airbus gap with 25% less weight, 40% greater capacity and 50% less carbon emissions, to enter service by early 2030s.

Rendering of the Horizon blended wing body (BWB) passenger aircraft being developed by Natilus. Source (All Images) | Natilus

Natilus (San Diego, Calif., U.S.) has announced launch of the Natilus Horizon blended wing body (BWB) aircraft, a step forward in sustainable commercial aviation for the underserved 200-passenger narrowbody market. Horizon will be the company’s second aircraft in production, following the 2028 entry into service (EIS) of its Kona unmanned cargo aircraft, which has 460 pre-orders. Horizon’s EIS is targeted for the early 2030s.

Natilus (pronounced NAW-tuh-luhs) was co-founded by Aleksey Matyushev and Anatoly Star in 2016 to develop the Kona aircraft, a BWB design for companies like UPS, FedEx and DHL to solve the problem of limited volume and high costs in traditional tube-and-wing cargo aircraft. Kona will now be joined by Horizon, a hyper-efficient BWB aircraft designed to be 25% lighter, provide 40% greater capacity and emit 50% less carbon than aircraft used in commercial aviation today. Both aircraft take advantage of Natilus’ mild BWB design featuring a slender lifting fuselage, high aspect ratio wings and twin aft-mounted engines.

Kona

Natilus’ inaugural aircraft, Kona, is an 85-foot wingspan, 19,000-pound aircraft — which means it can be certified per General Aviation guidelines — with a payload of 3.8 metric tons and a range of 900 nautical miles. Kona’s construction is 80% carbon fiber-reinforced polymer (CFRP) composite and 20% metal. The latter is used in Kona’s twin vertical tails and control surfaces, while the BWB fuselage will be CFRP. Kona will reportedly provide customers with double the cargo volume for each trip, while simultaneously reducing cargo transport cost by up to 60%.

Natilus announced in 2022 that it would partner with Janicki (Sedro-Wooley, Wash., U.S.) for composite part design and fabrication, citing the veteran composites tooling and technology supplier’s renowned reputation for innovation and quality workmanship. “We selected Janicki because they are a family-owned and operated company, founded and run by engineers with the highest qualifications and experience in designing large-scale, high-precision prototypes, tools and production parts,” says Natilus CEO Aleksey Matyushev.

Initial deliveries of Kona with twin Pratt & Whitney Canada (Longueuil, Quebec) PT6A-67D turboprops are expected in 2028. In April 2023, Natilus performed test flights with its sub-scale prototype and has recently completed its full-scale Kona prototype which will begin flight testing in 2025.

Horizon

Horizon is an BWB designed for the narrowbody market, accommodating up to 200 passengers and a payload of 25-28 metric tons on routes such as San Diego to Hawaii, Los Angeles to Boston, and New York to London. Its 118-foot wingspan will meet current limitations at airports, and though weight and payload will depend on the final configuration per customer and mission, the all-CFRP Horizon will deliver significant improvements thanks to the inherent aerodynamic and interior volume benefits of its BWB design.

In Aviation Week’s report by Guy Norris, Matyushev notes now is the right time to pursue Horizon because “the commercial aviation industry is looking for real solutions to become more sustainable, more efficient,and more profitable.” He adds that this timing “aligns with fleet purchasing decisions by commercial carriers to meet the airline industry’s 2050 net-zero goals.”

Next steps

While Natilus proceeds with certification and then first deliveries of Kona, it will also move forward with finalizing the design for Horizon. To meet the target of EIS in the early 2030s, this will need to happen quickly. “That’s 6-7 years away, but from our perspective, it’s not a lot of time,” Matyushev says. “So, we already have wind tunnel testing scheduled for next year, and toward the end of that, we have to freeze the design. Then we’ll start working on the internals, systems and manufacturing that will enable us to achieve our first flight goals.”

One strategy that will help is the use of already commercialized and available engines, landing gear, avionics and other systems — an approach Natilus is also using for Kona. And, as can be seen with Janicki, it is also working with trusted subcontractors.

The company also benefits from an experienced in-house team who have worked on more than 25 aircraft programs spanning commercial, military and general aviation and including innovators from General Atomics, Northrop Grumman, Skunkworks and SpaceX. It is also drawing on the knowledge of its customer partners, which include major airlines, lessors and integrators such as Ameriflight, a regional feeder airline for UPS, as well as Volatus Aerospace, Flexport, Astral, Aurora International, Dymond and others.

The company’s key investors — including Draper Associates, VU Venture Partners, Starburst Ventures, Mubadala, Seraph Group, New Climate Ventures, Soma Capital, Type One Ventures and Liquid 2 Ventures — are supporting this next step forward with Horizon. “We’ve been asked by key players in the market to do this,” says Matyushev, “and we finally realized this is the right time, which is exciting, but also challenging. We see that BWB aircraft have become more normalized and that the market needs new solutions. We’re trying to essentially take our design and put it together with existing materials, manufacturing and systems in a unique way that will provide the opportunities and efficiencies our customers want in the near-term.”

Related Content

Partners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

Read MoreJEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

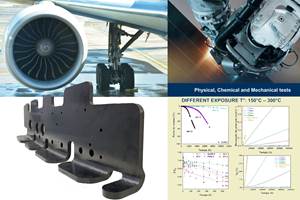

Read MoreDaher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

JetZero accelerates BWB airliner development with $235 million Air Force award

The commercial/military composite aircraft design will offer a 50% reduction in fuel burn and emissions with potential for future conversions to hydrogen.

Read MoreNatilus partners with Janicki for blended wing autonomous aircraft

The Tier 1 supplier will design, fabricate and provide quality assurance of primary composite structures for the Natilus N3.8T prototype, to be used for air freight transport.

Read MoreComposites-intensive UltraFan aeroengine achieves full power milestone

Rolls-Royce full power engine test with sustainable fuel set to deliver efficiency improvements in aviation for future narrowbody and widebody aircraft.

Read More

.jpg;maxWidth=300;quality=90)