New AMRC facility, Boeing program boosts aerocomposites innovation

An £80 million investment contributes to a novel R&D facility in South Yorkshire, U.K., with Boeing as its first major research partner, to support and de-risk new composites and digital technologies and processes for the production of future aerospace components.

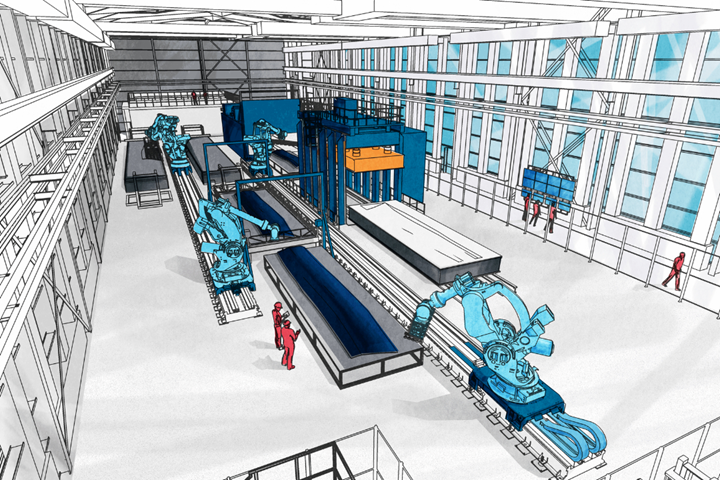

An artist impression of the new Compass facility. Photo Credit, all images: University of Sheffield AMRC

The University of Sheffield Advanced Manufacturing Research Centre (AMRC, Catcliffe, U.K.) has secured £50 million to establish the Compass (Composites at Speed and Scale) facility in Sheffield. Compass is expected to be a major boost to aerospace research and development (R&D) for the U.K., helping solve composites manufacturing challenges needed to meet future demand for lighter commercial aircraft and help the aviation industry reach net zero.

Compass will be home to AMRC’s largest ever collaborative R&D program with founder and long-standing member Boeing (Arlington, Va., U.S.), which will be in partnership with Spirit AeroSystems (Wichita, Kan., U.S. and Prestwick, Scotland) and Loop Technology (Dorchester, U.K.). It aims to de-risk and develop high-rate sustainable structures, with the potential to reduce large component process times from ~40 hours to approximately 4 hours.

Compass will push the boundaries of existing science and technology, according to the AMRC, enabling automation of the layup of large-scale composite components to move beyond existing capabilities. Drawing on relevant state-of-the-art R&D with industry, it will:

- Enable run-at-rate demonstration of large-scale automated manufacturing processes.

- Develop precise pick-and-place and in-line inspection technologies to support tolerances required by aerospace.

- Develop a digital twin of the facility and process. This will allow the industry to start development work virtually and support existing research into virtual commissioning.

- Use fully sensored processes and equipment, linked together in a flexible control architecture, providing a single source of truth for the validation of parts/processes, and enabling active control responding to changing process environments.

- The data, gathered over time, will enable future research in artificial intelligence and machine learning techniques for factory-scale process optimization.

On the back of this research, Boeing has committed to procuring in excess of £2 billion of U.K.-manufactured goods for export per year to support the production of the company’s next civil passenger aircraft — with the potential to create up to 3,000 high-skilled jobs by the mid-2030s.

Compass builds on the AMRC’s composites and automation capabilities to de-risk the development and manufacture of high-rate, large-scale composite parts, providing the wider U.K. industry with an open-access facility to develop, demonstrate, test and validate new composites manufacturing technologies and capabilities. It is noted that the Compass project puts the U.K. supply chain in a competitive position to win production contracts for future next-generation aircraft.

Chancellor of the Exchequer, Jeremy Hunt, visiting the University of Sheffield AMRC's Factory 2050 facility in Sheffield, accompanied by AMRC CEO Steve Foxley and Boeing president Maria Laine.

“Compass will help to establish South Yorkshire as the leading R&D center of excellence in the manufacture of composites at speed and at scale, enabling future production capabilities that currently don’t exist,” Steve Foxley, CEO at the AMRC, explains. “This facility, alongside our existing pedigree and the work on hydrogen and sustainable aviation fuels in the wider University of Sheffield, are cornerstones of a future green aerospace cluster in the region.”

The research with Boeing builds on more than 20 years of collaboration and innovation with the AMRC, and the investment it has made into South Yorkshire with Boeing Sheffield, the company’s only European manufacturing facility, and the partnership with the University of Sheffield for its Sustainable Aviation Fuels Innovation Centre.

The building is being jointly funded by the South Yorkshire Mayoral Combined Authority (SYMCA), Sheffield City Council, University of Sheffield and the High Value Manufacturing Catapult. It will be home to a raft of state-of-the-art equipment secured through a £29.5 million grant from the Aerospace Technology Institute (ATI) to support new capabilities, technologies and processes to reduce cost, waste, production time and associated carbon emissions.

Ultimately, Compass will harness the power of data sharing to fuel innovation with manufacturing production data a key output of the facility and its research. It will use data, cyber-physical infrastructures and robotic automation to generate a large manufacturing data pool to help the wider business and research community develop solutions to unlock the value to become smarter and more productive.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRead Next

IACMI receives funding renewal from U.S. DOE to continue composites R&D

Over the next five years, IACMI aims to further composites R&D efforts to support U.S. decarbonization and its pillars: technology, economy and workforce development.

Read MoreOpening of NMIS facility advances future manufacturing in Scotland

With innovation at its heart, the new R&D hub is set to be a catalyst for economic growth, home to a collaboration hub, full connected Digital Factory, materials division, Lightweight Manufacture Centre and more.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More