New name for Fraunhofer lightweight construction cross-sector R&D, focus on multifunction and digitization

Research results from 2020 show breadth of applications and novel composites technologies for next-gen mobility.

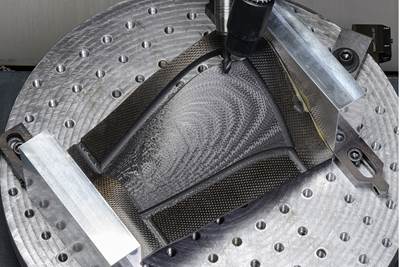

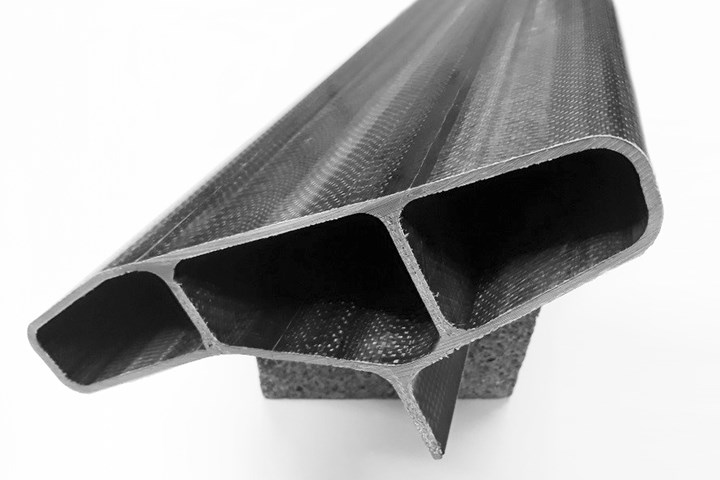

Fraunhofer IWU (Chemnitz, Germany) has developed pultruded carbon fiber composite side skirts that are lightweight, meet crash loads and can be reused at the end of an e-car’s life. Photo Credit: Fraunhofer Institute for Machine Tools and Forming Technology IWU.

Under the umbrella of the Fraunhofer-Gesellschaft, 15 partner institutes in lightweight construction research and development (R&D) contribute to solutions along the entire value chain in manufacturing processes as well as analysis and evaluation methods. They bundle their know-how and can thus specifically address the technical as well as business and eco/environmental requirements of innovative companies. They can also provide a comprehensive range of advanced training courses with specifically tailored modules.

Previously operating under the name “Fraunhofer Lightweight Construction Alliance,” this partnership will now continue as “Fraunhofer Research Field Lightweight Construction” with the focus in 2021 on the integration of additional function(s) and digitization — an important contribution to achieving the world’s climate goals.

“We will continue our cooperation under the new name in the established manner, but we also have some new priorities for the beginning of the year,” says Dr. Michael Luke from the Fraunhofer Institute for Mechanics of Materials IWM (Freiburg, Germany). Dr. Luke has been the spokesperson for the partner institutes’ joint research activities in the field of lightweight construction since 2020. “In terms of technology, functional integration and digitization will be in the foreground in 2021, taking climate targets into account.” Fraunhofer Research Field Lightweight Construction will present research results, technologies and solutions at the LightCon - New Congress Fair for Lightweight Construction (Hanover, Germany) in June 2021.

Research Results 2020: Sustainable Mobility and AI

The breadth of Fraunhofer’s lightweight construction R&D applications becomes clear from a selection of the institutes’ research results from the past year:

The Fraunhofer Institute for Machine Tools and Forming Technology IWU (Chemnitz, Germany) has developed new construction methods for body parts in automotive engineering as part of the EU project “FiberEUse.” As part of a long-lasting fiber composite vehicle structure, pultruded side skirts are not scrapped at the end of the life of an e-car. With the help of the associated remanufacturing technology, they can be reused. This is an important step towards an automotive circular economy. The lightweight components are not only inexpensive to manufacture, they also meet the highest crash requirements.

The “Last-Light-Construction-Bike (L-LBF)” of the Fraunhofer Institute for Structural Durability and System Reliability LBF (Darmstadt, Germany) also helps protect natural resources. Not only is it 40% lighter than comparable, commercially available cargo bikes, but thanks to the special design, it also drives much further because there is significantly more space for a battery in the new lightweight frame.

“Vision PI” is a sustainable mobility concept for the future. It was designed jointly by six Fraunhofer institutes and combines modern technologies, resource protection and the need for an individual lifestyle. The concept consists of a passenger cell that has a modular structure based on the logic of a shell principle and can be flexibly adapted to the needs of travelers: During the day it serves as a communicative lounge, at night it becomes a relaxation capsule for a relaxing long-distance journey. The interior is flexibly adaptable and adaptive in its settings. The materials used consist of renewable raw materials or are designed to be optimally recyclable. The entire module can be coupled to various mobility carriers — depending on the needs of a vehicle platform, an air taxi or a Hyperloop solution. It can also be converted into an interactive virtual reality lounge, which enables unlimited virtual travel around the world and thus contributes to an innovative component of new mobility and building designs.

The researchers at the Fraunhofer Institute for Foundry, Composite and Processing Technology IGCV (Augsburg, Germany) use artificial intelligence (AI) to develop an optical measurement system for carbon fibers that are used in aviation for helicopters and airplanes. It enables micro-defects to be monitored seamlessly during production and negative process influences to be identified early on. Learning neural networks reliably recognize whether a component is a good or bad part. This means that disruptions in the production process — such as tow twists or breaks — can be avoided. The system also provides data that can be used to significantly improve process stability in carbon fiber composites production.

In addition, the partner institutes continue to put great effort into the Fraunhofer project framework “Innopsuh” that deals with new lightweight structures and accelerated development processes for eco-efficient driving (“Light Materials 4 Mobility” project). Digitized material and data value chains, as well as resource-efficient data systems, are also designed in this project framework. They are intended to support the digital transformation in materials manufacturing. A suitable reference architecture is being set up for this purpose (“DMD4Future” project).

This is a press release from Fraunhofer Institute for Machine Tools and Forming Technology IWU, mail: christian.schaefer-hock@iwu.fraunhofer.de

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

Fraunhofer IPT automates production of thermoplastic CFRP engine fan blades

Successful first demonstrations on 16-mm-thick CF/PA12 to be followed by CF/PEEK tapes and embedded sensors for structural health monitoring (SHM).

Read MoreFraunhofer IFAM automates pre-assembly of CFRP fuselage frames

Positioning and drilling end effector for automated, high-precision and quality-assured pre-assembly developed with Airbus in German-funded “Tempo” sub-project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)