Nikola Corp. selects Hexagon Purus to supply Type IV hydrogen cylinders for serial production

High-performance composite pressure vessels to be tested and validated later in 2021, and certified for distribution in European and North American markets.

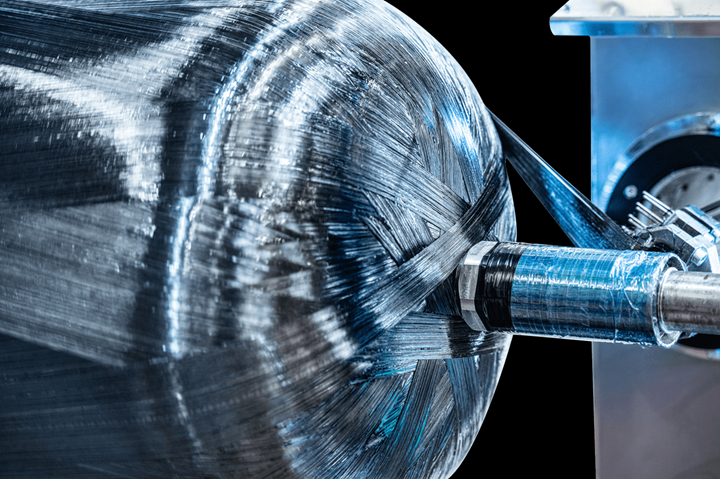

Photo Credit: Hexagon Purus

Hexagon Purus GmbH (Ålesund, Norway) has signed a long-term agreement with Nikola Corporation (Salt Lake City, Utah, U.S.), a zero-emissions transportation and infrastructure solutions company, to develop and supply its high-performance Type IV composite hydrogen cylinders. The scope of the agreement is over a multi-year period with an estimated sales value in excess of €200 million (approx. $242 million).

The project’s development phase will commence in Q2 2021. The technology is planned to be certified for distribution in European and North American markets. The long-term agreement also positions Hexagon Purus for potential further projects within a range of truck and other vehicle applications with Nikola.

“We are proud to partner with Nikola and support the delivery of its flagship hydrogen fuel-cell trucking solution. Putting these hydrogen-powered trucks on the road will accelerate the energy transition in heavy-duty transportation,” says Michael Kleschinski, EVP Light Duty, Distribution & Cylinders, Hexagon Purus. “The first Hexagon Purus 700 bar hydrogen cylinders will begin testing and validation later this year in accordance with Nikola’s specifications.”

Related Content

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.