NLR, Synthesites work toward intelligent manufacturing for aerospace structures

NLR acquires fully operational intelligent resin monitoring system for noninvasive, real-time resin viscosity and glass transition temperature estimation.

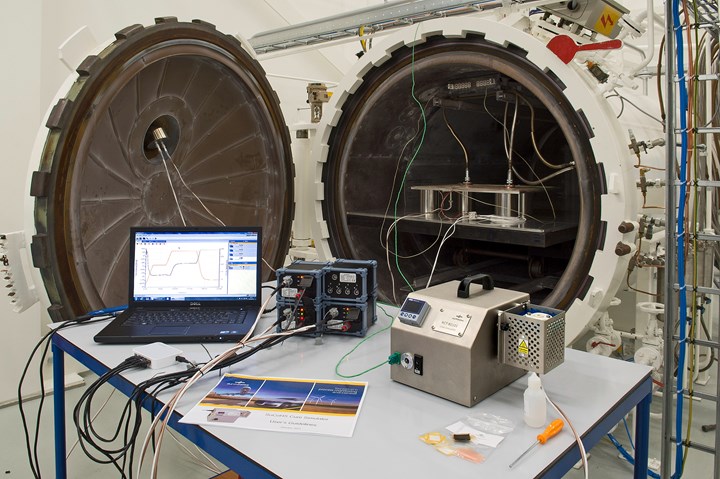

NLR Cure Simulator. Photo Credit: NLR, Synthesites

Following the successful collaboration within the European-funded project, SuCoHS, the Netherlands Aerospace Centre (NLR, Marknesse, Netherlands) has acquired from Synthesites (Uccle, Belgium) a fully operational intelligent resin monitoring system for the noninvasive online estimation of viscosity and glass transition temperature (Tg) for advanced composites manufacturing.

This system is an extension of NLR’s thermal analysis capabilities and process simulations as part of Industry 4.0 and digital twin developments. It includes an Optimold unit (resistance and temperature) and two Optiflow units (resin arrival and temperature) coupled with Online Resin State (ORS) software and the Cure Simulator for real-time estimation of the resin viscosity at injection and Tg, requiring no intervention to the mold or the autoclave (learn more, “DC dielectric sensors for industrial composites production”).

Synthesites is working with leading manufacturing companies in aerospace, automotive, industrial and wind energy, world-class research centers and universities, to provide advanced solutions for process optimization, online quality and process control to save considerable processing time and significant energy.