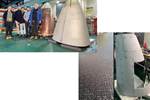

Norco develops composite clamshell coverings to protect Siemens engines

The IP55-related GFRP clamshell cocoons protect gas turbine engines during transport while simplifying loading and unloading processes.

Siemens Energy (Munich, Germany) partnered with Norco (Poole, Dorset, U.K.) to develop IP55-rated glass fiber-reinforced plastic (GFRP) cocoons for the company’s range of gas turbine engines.

Previously, Siemens relied on heavy, cumbersome bags that inadequately protected the engines, especially during air transport where steel containers that weighed as much as the engines themselves had to be used. Alternatively, the lightweight composite protective shells developed by Norco offer secure storage and transportation, keeping the engines dry and safeguarded against impact damage.

The engineering phase involved light scanning the engines using GOM photogrammetry due to the sensitive nature of the 3D CAD data. Design was carried out in Siemens NX, incorporating additional service specifications. Norco applied resin infusion methods to create lightweight but high-quality laminate cocoons with excellent stiffness and damage tolerance. The final product is a glass fiber-reinforced part with Kevlar for additional impact performance, and marine-grade fittings for offshore use. The cocoons are also weatherproof and sealed, passing dust and moisture ingress tests to IP55 standards.

They are equipped with a perimeter seal and a 110-volt dehumidifier, simplifying the loading and unloading of the engines. The design also enables positional adjustments of up to 50 millimeters vertically and 100 millimeters horizontally, offering safer and more straightforward engine loading. The base of the cocoon accommodates essential components like the gearbox and starter motor, eliminating the need for their removal and further reducing operational time.

The dubbed Clamshell Cocoons are now in active service. Norco’s ongoing service with Siemens and its customers highlights the company’s proficiency in delivering tailored composite manufacturing solutions.

Related Content

-

Understanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

-

Automotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

-

Al Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.