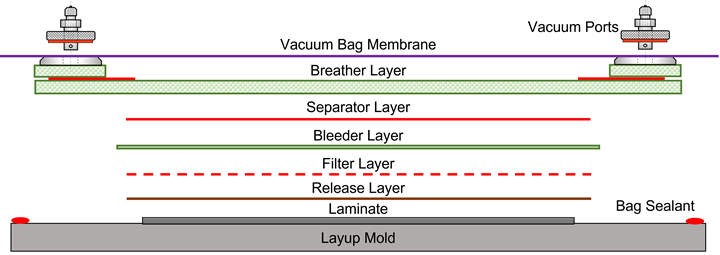

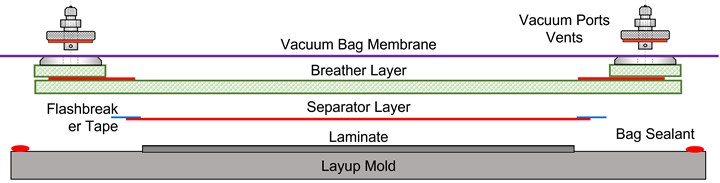

Figure 1. Vacuum bag schedule. This illustration shows a number of different layers/functions that can be deployed within a vacuum bag for processing a composite laminate. This type of arrangement might be applicable to a vacuum bag only (VBO) type process but in no way is it universal to all applications. Photo Credit, all images: Abaris Training Resources

The advanced composites manufacturing industry uses more vacuum bagging materials than they do almost any other consumable product. There are numerous materials specified for use under the vacuum bag film itself. Each layer provides a different function necessary to a specific method of processing — for example, vacuum bag only (VBO), in or out of an oven, autoclave, vacuum infusion and more — not to mention multiple vacuum compaction (debulk) operations that might be prescribed for a given layup. The materials must be capable of surviving the process (cure) temperature without degrading. Exploring these materials and their functions in more detail can help users better understand vacuum bagging schedules used in production and repair.

The vacuum bag schedule is made up of a series of materials that provide a variety of services: bagside release from the laminate, resin bleed, resin filtering or blocking, breathing (allowing gas to escape during processing) and maintenance of continuous atmospheric differential pressure on the laminate (Fig. 1). The descriptions of each function along with common materials are discussed as follows.

Release layer

The release layer is a material that can be removed from the backside of the laminate after processing, therefore preventing the other layers from sticking to it. A fabric peel ply or a release film is typically prescribed for this purpose. The type of material specified depends on whether the intent is to stop, filter or allow resin to flow through this layer and what surface texture is desired. Dry peel ply and fiberglass fabric coated with polytetrafluoroethylene (PTFE) are materials commonly deployed at this level.

Dry peel ply is a porous nylon or polyester fabric that enables resin and gas to flow into or through the layer. It is multifunctional in this application as it can provide release from the laminate and move/absorb resin during processing. There are many types of dry peel ply, ranging from lightweight and finely woven to heavy-duty (coarse) fabrics that leave a corresponding texture on the backside surface of the laminate. (Note: a “wet” or prepreg peel ply might be prescribed for this function but would be called out in the layup schedule for the laminate and not in the bagging schedule.) Once the peel ply is removed from the laminate, the resulting surface may be suitable for painting or bonding, depending upon the materials used and the texture that remains.

PTFE-coated fiberglass fabric can also be used as a peel ply layer. There are two versions designated as either Teflon fabric porous (TFP) or Teflon fabric non-porous (TFNP). The TFP version allows resin and gas to flow through the layer, but it does not necessarily absorb resin in the same manner as dry peel ply. The TFNP blocks resin flow into or through the layer, but it is permeable to some gases under pressure. With both of these fabrics, the resulting surface is unsuitable for bonding due to the low surface free energy created by the TFP/TFNP contacting this surface (few available polar arrangements to attract wetting).

Release film is another option for material at this level — a solid film is prescribed to block all resin movement, and a perforated film allows resin movement. These can be made from polymethyl pentene (PMP), polyethylene terephthalate (PET), fluorinated ethylene propylene (FEP), polyolefin or other polymers. These films leave a glossy, low energy surface on the backside of the laminate, which is also unsuitable for bonding.

Filter layer

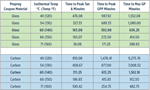

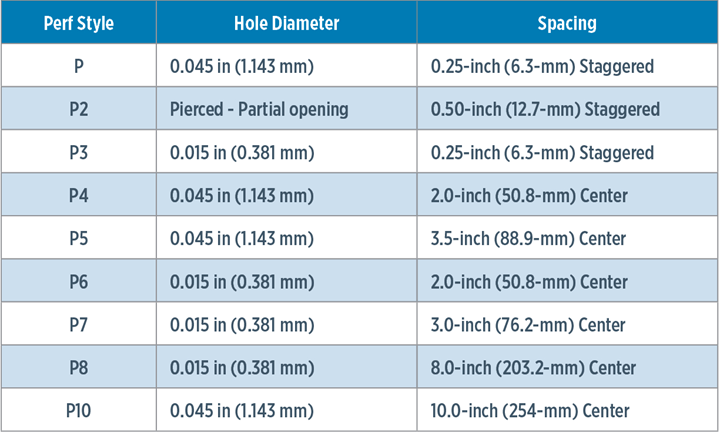

The filter layer is designed to allow a regulated amount of resin and gas to pass from an underlying layer (or laminate) to the next layer above. The material is a perforated version of the above-mentioned release film with a pierced puncture (flap, no hole) pattern or either 0.015- or 0.045-inch-diameter holes — available with hole spacing between 0.25 to 10.00 inches apart, staggered or on-center. These materials are available as off-the-shelf products1 with common perforation style designations (for example, P, P2, P3, etc. per Table 1) or the user can self-perforate solid release film to any pattern and hole size they desire. In addition to inter-schedule use, perforated film is typically used as the release layer against the laminate when performing debulk operations. A filter layer is not necessary if the prior layer is non-porous.

Table 1. Perforation styles table. A partial list of perforation styles that are available from various vacuum bag material suppliers.

Bleeder layer

The bleeder layer is just that — a layer (or layers) of absorbent material that will determine the volume of resin that can be “bled” directly from a previous layer or as regulated through a filter layer. The bleeder layer is generally used in out-of-autoclave (OOA) processes to allow resin and gas movement from the laminate into the breather system (see “Breather layer” below). Bleeder materials range from fine-woven glass fabric to nonwoven polyester (“baby blanket”) material. The fine-woven glass leaves a uniform texture on the backside of the laminate — the nonwoven polyester material leaves a more irregular surface. This may be a consideration for areas that have surface profile or roughness tolerances, or for aerodynamic composite repairs.

Separator layer

The separator layer is designed to stop resin from flowing from one layer to the next. It is typically used between the bleeder layer and the breather layer, but it can also be used as a release layer between the laminate and the breather in a bag schedule designed for autoclave processing, as depicted in Fig. 2. Typically, a solid release film is used for this purpose. However, any material that stops resin flow can be used as a separator — for example, TFNP or bagging film. The latter should not be directly against the laminate unless it is made from a low-energy, release-capable polymer. (See “Vacuum bag membrane” below.)

Figure 2. Vacuum bag schedule for autoclave. Fewer materials are necessary for autoclave processing, as the need to move resin and gas can be accomplished at higher pressures without a bleeder system.

Breather layer

The function of the breather layer is two-fold. First, it acts as a continuous path under the bag membrane to enable differential atmospheric pressure to be equally distributed across the part area. Second, it is the route for volatiles and other gases to escape from the arrangement under the bag through the vacuum ports and hoses into the vacuum system and eventually to the atmosphere.

The materials used for the breather are like those used for the bleeder but often have more bulk so that they do not seal off under pressure. Ten to 18 ounce per square yard (339-610 grams per square meter) nonwoven polyester materials are common for up to 100 psi (6.9 bar). For higher pressures (or temperatures), heavy glass fabric might be specified to meet the process requirements. Premium nonwoven, blended fiberglass breather is available for ultrahigh temperature and pressure use. This material also may be better suited as a breather layer over complex geometries, where a glass fabric may be prone to bridging.

Vacuum bag membrane

The vacuum bag membrane is a pliable, nonpermeable film layer used to separate the interior of the bag from the outside environment — providing differential clamping pressure on the laminate during processing. The film material is selected based upon the upper temperature it will see and the durability required to survive the process. Increased bag thickness improves durability but at the risk of losing malleability. Materials range from polyolefin to nylon to polyimide to thermoplastic elastomers and other hybrid formulas, each having different thermal properties and performance characteristics.

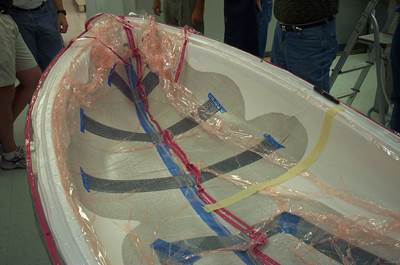

While there is much more to learn about vacuum bagging, understanding the function of each layer can help users better analyze their needs and, therefore, design vacuum bag schedules that work the best for their specific applications (Fig. 3). This task is often left to material and process engineering in the larger companies, but it applies to everyone who needs insight into the functionality of the bag schedule as a system.

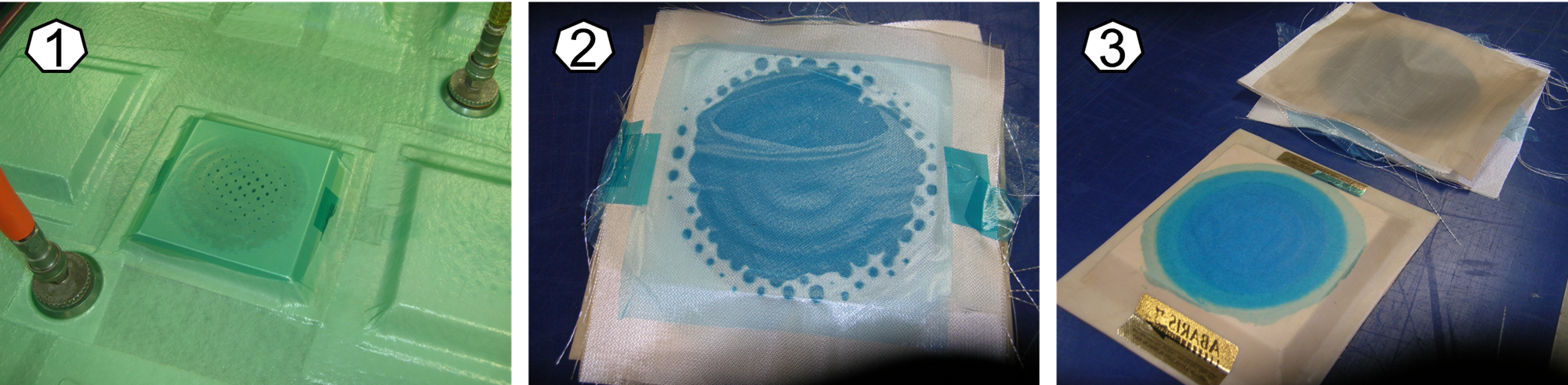

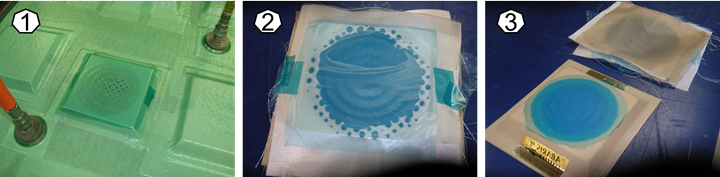

Figure 3. Bag schedule for composite repair. An example of a bag schedule used for composite repair. (1) The resin bleed is visible on one panel just under the bag. (2) A top view of the bleeder schedule after processing and after removal of the bag. (3) The schedule layers consist of a TFP peel ply release layer, a #1581 style glass fabric bleeder, a P3 perforated film filter layer, another #1581 style glass fabric bleeder layer and a solid film separator layer. These were all under a breather layer, inside the bag.

References

- Perforation styles and material types from Airtech International Inc., (Huntington Beach, Calif., U.S.), https://www.airtechintl.com

Related Content

TCR Composites introduces TR1116 snap-cure epoxy prepreg resin system

Designed for press-cure applications, the resin system is highlighted for its snap-cure capability and tailored properties.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreDLR completes MFFD upper shell skin layup

Eight-meter-long CFRTP fuselage skin was achieved via laser-heated in-situ consolidation, with stringers, frames and cleats to be welded.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreRead Next

Real-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreTech Table: Vacuum bagging supplies

This is the fifth in a series of Tech Tables and comprises vacuum bagging material data provided by suppliers.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More