People on the Move: July 2018

CW’s monthly roundup of people on the move in the composites industry.

4M Carbon Fiber Corp.

4M Carbon Fiber Corp. (4M, Knoxville, TN, US) announced July 24 that Garo Artinian, president and CEO of Artinian Holding (West Palm Beach, FL, US), a global business advisory, has been appointed to the company’s Board of Directors.

Prior to his appointment, Artinian served as the chairman and CEO of Draka Holding NV (Amsterdam, Netherlands), a publicly traded company, from 2003 to 2006. There, he helped grow revenues to more than three billion euros by restructuring the company’s debt, reorganizing its operations into a leaner and more focused structure, and expanding sales in key international markets. He also completed a joint venture with Alcatel (Warrenton, VA, US), creating the second largest communications wire and cable company in fiber and copper worldwide. Guided by Artinian’s strategic vision, the venture successfully integrated several acquisitions. Together, these actions drove positive cash flows, improved collaboration between divisions and management, and in effect, turned the business around.

In 2006, Mr. Artinian retired from Draka and launched Artinian Holding, which specializes in supporting CEOs as they expand and integrate their businesses. Since then, he has served on the boards for Domaille Engineering (Rochester, MN, US), TPC Group (Houston, TX, US), and Dura-Line, which was acquired by Mexichem (Tlalnepantla, Mexico) in 2014.

KraussMaffei

KraussMaffei (Munich, Germany) reported on July 20 that on July 1, Dr. Stefan Kruppa took over as head of the recently established Smart Machines business unit of KraussMaffei Group. In this new unit, all machine-specific digitalization solutions will be managed and made available across segments and brands. It is part of the recently formed segment Digital Service Solutions which was launched at the same time. Expanding the organizational structure is part of KraussMaffei Group's new corporate strategy; its implementation has just started.

In his new position as Director Smart Machines, Kruppa will focus on the further development of new intelligent systems and solutions for all three plastics processing technologies with which the KraussMaffei Group is represented on the global market: injection molding, extrusion and reaction processing. "While KraussMaffei will obviously continue to build top-quality machines, my job is to refine them with digital features, additional products and services," says Kruppa, explaining his new function.

The "Smart Machines" unit is divided into three pillars: Machine technology (e.g. intelligent machines), connected solutions (e.g. Internet of Things) and data analytics (e.g. big data). Medium-term, innovative business models will be generated from development work and the interaction of these units to meet new customer needs and changing demand.

Kruppa joined KraussMaffei in 2010 and was most recently responsible for machine technology. In 2015 he received his doctorate at the University of Duisburg-Essen with a thesis on "Adaptive process control and alternative injection concepts for injection molding of thermoplastics."

The Digital Service Solutions segment is part of KraussMaffei Group's new corporate strategy. This strategy includes further developing the cross-segment, global service business, developing and expanding digital services and products as well as new business areas.

NLign Analytics

NLign Analytics (Cincinnati, OH, US) announced June 25 the appointment of Craig Rees as vice president of Sales.

Tom Sharp, CEO of NLign Analytics says, “NLign is growing by delivering value across departments for our customers—from management and engineering, to inspection and quality—and by bringing the benefits of NLign to other commercial and government customers. We are uniquely positioned to deliver proven new solutions for customer strategies, including Digital Thread and Digital Twin. Craig’s hiring strengthens our sales and marketing team and will allow us to accelerate revenue growth across aerospace and defense markets.”

Rees brings to NLign over 15 years of consultative software sales experience assisting customers with product innovation, reliability, efficiency and quality. Rees comes from ANSYS, where he served in sales leadership roles throughout the US with an emphasis on the aerospace and defense sector, including across the DOD and DOE. He has a proven track record of creating customer success through the sale of technical products and is known for his ability to closely collaborate with partners.

“Having worked with the top aerospace and defense companies in the world, I see a big gap between their engineering and operations,” says Rees. “NLign connects manufacturing and product field performance to CAD/CAE models to complete the Digital Thread. I am excited to join the NLign team and help customers drive down costs of rework and maintenance while improving product performance and operating margins.”

SAERTEX

Effective July 1, SAERTEX (Saerbeck, Germany) has realigned the operational management of the group. For this purpose, the company has transferred management to the SAERTEX Global Executive Board with Christoph Geyer as the new chief executive officer (CEO). Christoph Geyer has been a member of the SAERTEX Group managing board since October 2016 in the role of chief sales officer (CSO) and, in future, will also be responsible for the global sales activities of the company in addition to his new role as CEO. The other members of the Global Executive Board are Dr. Guido Kritzler as chief financial officer (CFO) and Dietmar Möcke as chief technology officer (CTO).

Safran Nacelles

Member of the Executive Committee and reporting directly to Safran Nacelles CEO Cédric Goubet, Pierre Cottenceau joins Safran Nacelles (Le Havre, France) to take the responsibility of the Engineering division.

In 1999, Pierre began his career with Messier-Dowty Ltd. (Gloucester, UK) — now known as Safran Landing Systems — on the European Enhance project (collaborative engineering). He then joined Messier-Dowty Vélizy in 2000, successively occupying the positions of A340-500/600 systems engineer, modelling and simulation project leader and then A400M programme chief engineer in charge of developing the landing gear system of the Airbus A400M. In 2008, Pierre went to work for Sagem Avionics Inc. (Dallas, TX, US) — now known as Safran Electronics and Defense — as vice president of Programmes & Product Development, in charge of auto-pilot and cockpit display activities.

He joined Safran Aircraft Engines in 2011 as chief engineer for the LEAP-1B engine. In September 2016, he was appointed head of the design office in charge of controls and externals, and then in July 2017, he became director of the Propulsion System design office, which includes the External Systems division and the Propulsion System Integration division.

Society for the Advancement of Material and Process Engineering (SAMPE)

SAMPE (Diamond Bar, CA, US) has announced the new officers of the SAMPE North America Cabinet for the 2018-2019 term. The group will lead SAMPE North America's goals and strategies over the next year.

- President - Karin Anderson, Structures Analyst, The Boeing Company

- Executive Vice President - John D. Russell, D.Sc., Technical Director, Air Force Research Laboratory

- Vice President - Tim Shaughnessy, President & CEO, Rapid Cure Technologies, Inc.

- Treasurer - Scott Stephenson, Conference Director, CompositesWorld

- Secretary - Jerome Berg, Staff Engineer, Orbital ATK, Flight Systems Group

- Parliamentarian - Sarah Cox, Materials Engineer, NASA

- Immediate Past President - Ben Dietsch, President - NONA Composites LLC.

SAMPE’s North America Executive Cabinet and its Board of Directors will next meet at CAMX – The Composites and Advanced Materials Expo on October 15, 2018, in Dallas, Texas.

Southeast Nonwovens Inc.

Southeast Nonwovens Inc. (Clover, SC, US) co-founder Steven F. Nielsen has announced his retirement. Nielsen began his nonwoven journey with Manning Paper Company where he learned how to make specialty papers and wet-lay nonwovens. Eight years later he was recruited by Celanese to help develop polyester fiber for wet-lay nonwovens.

After the merger of Celanese with Hoechst AG, Nielsen was recruited to take a position in the newly formed Innovation Group where he led two different teams through the stage-gate process from conception to commercialization. In 1995 Hoechst AG started a divestment program which included the Fibers, Films and Chemicals divisions. Rather than move with the newly divested entities, Nielsen had the idea of combining his experience working with customers to develop new products with his knowledge of new business development. Nielsen called one of his friends at Manning Paper, Bryan Thomas. Tomas was also keen on the idea of starting a privately-owned R&D company for nonwovens. A few months later in October of 1997, Southeast Nonwovens Inc. was launched.

The past twenty-one years as President of Southeast Nonwovens, Inc. has been filled with interesting and stimulating challenges as Steve watched the industry evolve.

“I’ve enjoyed every day. I especially enjoyed meeting and working with so many of the great people associated with the nonwovens industry. The time at SENW has been a great experience I would not trade for anything,” says Nielsen. “At this stage in my career and time in my life I’ve done all I set out to do at SENW. I want to see the company continue and prosper so I believe it’s time for some new blood to come aboard. Bryan will take over the day to day leadership activities as President. I know he will do a great job.”

Nielsen remains a major share-holder and Chairman of the Board of Southeast Nonwovens Inc. and will work on special projects in an advisory role.

Related Content

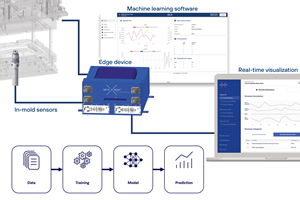

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MoreSchrödinger advances materials informatics for faster development of next-gen composites

Cutting time to market by multiple orders of magnitude, machine learning and physics-based approaches are combined to open new possibilities for innovations in biomaterials, fire-resistant composites, space applications, hydrogen tanks and more.

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

Read MoreAerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More