Rocket Lab successfully deploys four Alba Orbital PocketQubes into circular orbit

A new goal for the carbon fiber-reinforced 3D printed nanosatellites was achieved, including a sun synchronous orbit and a successful recovery mission.

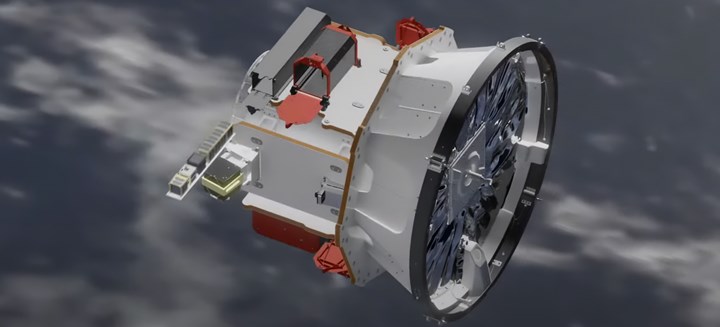

Deployment of the four PocketQube satellites from 3D printed Alba Orbital’s deployer during Rocket Lab’s mission. Screenshot from Rocket Lab YouTube channel

Alba Orbital’s (Glasgow, U.K.) PocketQube deployer, 3D printed by CRP Technology (Modena, Italy) using Windform XT 2.0 carbon fiber materials, has reached a new milestone, successfully taking part in the latest Rocket Lab (Long Beach, Calif., U.S.) space mission, deploying four PocketQubes into circular orbit. The launch, which occurred from Pad A at Rocket Lab Launch Complex 1 on New Zealand’s Mahia Peninsula, was also a recovery mission where, for the first time, Rocket Lab caught the launch vehicle’s first stage as it returned from space under parachutes using a helicopter. This was Alba Orbital’s second launch of 2022 (see “3D-printed composite PocketQube deployer delivers 13 nanosatellites to space in SpaceX Falcon 9 launch”), named “Alba Cluster X.”

Rocket Lab’s “There And Back Again” mission comprised 34 satellites launched to a sun synchronous orbit, four of which were Alba’s carbon fiber-reinforced systems 3D printed via selective laser sintering, which Alba says CRP Technology has helped to improve with the creation and use of Windform materials.

The satellites on board the Alba Cluster X flight included Alba’s Unicorn-2F and three 1p PocketQubes on behalf of ACME AtronOmatic/MyRadar (Orlando, Fla., U.S.), that plan to launch a 250-satellite weather data constellation.

Unicorn-2 carries an optical night-time imaging payload designed to monitor light pollution across the globe. “Night Lights” data (the night-time satellite imagery) are said to provide crucial insights into human activities, enabling a host of applications such as monitoring light pollution, evaluating armed conflicts and disasters, empowering maritime surveillance, validating sustainable satellite tech. Unicorn-2F phoned home on the first pass.

All four PocketQubes were deployed to a 500-kilometer (approx. 311-mile) circular orbit by Electron’s Kick Stage, a spacecraft that provides in-space propulsion and maneuvering capability to ensure each satellite is deployed to a precise and unique orbit defined by the customer.

This one was also a recovery mission where, for the first time, Rocket Lab attempted a mid-air capture of Electron’s first stage as it returned from space using parachutes and a helicopter. The successful catch brings Electron one step closer to being the first reusable orbital small sat launcher.

Related Content

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.