SCABAEGO project develops bioactive composite that supports healing of broken bones

Fraunhofer IFAM researchers and partners combine biodegradable polymer polycaprolactone and bioactive glass to 3D print custom-fit structures for bone fracture sites.

Share

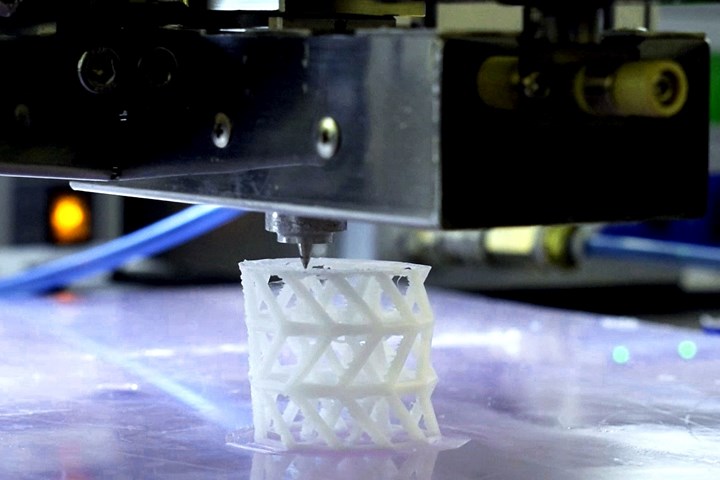

At the pilot plant, a 3D printer builds the scaffold from the composite material. Photo Credit: BellaSano

The Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM, Bremen, Germany) has provided a solution for the healing of broken bones through the SCABAEGO (Scaffold Bioactive Glass-Enhanced Osteogenesis) joint research project. The project’s aim is to test the working hypothesis that using bioactive materials in operations supports the healing process and reduces the risk of infection. The institute’s partners for the project include the Department of Trauma and Reconstructive Surgery at the Heidelberg University Hospital (Germany) as well as BellaSeno (Leipzig, Germany), a company specializing in medical engineering.

Fraunhofer IFAM researchers have developed a composite material from biodegradable polymer polycaprolactone (PCL) and bioactive glass. The composite material is then used to 3D print customized main and supporting structures — called scaffolds — for bone fracture sites. Prior to this, the structure of the damaged bone is mapped using computer tomography (CT). The custom-fit structure replaces the missing part of the bone. It is then filled with bone marrow taken from the iliac crest or from larger long bones. This promotes that the biological bone replacement material (autologous bone craft, ABG) is stably contained and the fracture site heals safely.

The medical product provides even more advantages. “The bioactive glass in the scaffold raises the pH of its surroundings to alkaline,” explains Dr. Kai Borcherding, head of the Medical Technology and Life Sciences business unit at Fraunhofer IFAM. “The next thing we want to investigate is the expected result of this, which is inhibiting bacteria growth.” The researchers expect this to reduce the risk of postoperative infection.

The bioactive glass also supports the growth of new bone at the fracture site. Because it is in contact with bodily fluids, the glass turns into hydroxylapatite, which is a chemical compound derived primarily from calcium phosphate and a substance very similar to bone.

“With bioactive glass, we can tackle the problems that clinics face — we can inhibit bacterial growth and provide effective support for bone healing,” says PD Dr. Tobias Großner, trauma surgeon and head of experimental trauma surgery at Heidelberg University Hospital. “After 6-7 years, the scaffold will be fully biodegraded and converted into bone.”

Bioactive glass is already used for treating bone defects. What’s new is combining it with PCL on an industrial scale. Fraunhofer researchers have succeeded in binding glass and PCL to create a composite material that can be used directly in additive manufacturing. The main result of this is that customized 3D scaffolds can be produced. It is simple and quick to produce the composite material on an industrial scale.

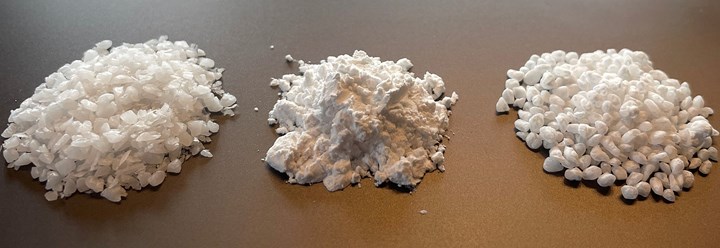

From PCL (left) to composite (right) containing bioactive glass (center). Photo Credit: Fraunhofer IFAM

“The PCL polymer is mixed with the glass granulate and a solvent before undergoing multiple processing steps,” Borcherding says. “At the end, the solvent is removed through drying, and the residual composite is finely ground.”

A CT scan of the damaged bone is taken to produce a 3D virtual image. Project partner BellaSeno then prints the scaffold from this material using a 3D printer that is said to perfectly fit the bone. “We use 3D printing so that we can create each scaffold individually to fit the fracture site for each patient,” says Dr. Mohit Chhaya, managing director of BellaSeno and project coordinator.

The SCABAEGO project research team are already investigating the concept in vitro and in vivo with preclinical tests, working alongside Heidelberg University Hospital. While these are ongoing, the recipe for the composite is being optimized. The proportion of bioactive glass in the scaffold can range between 10-30%.

“We are experimenting with the mixture proportions so that we can leverage the biologically positive characteristics of glass as much as possible while maintaining the core strength of the scaffold,” Borcherding says.

For related content, read “Bioabsorbable and degradable glass fibers, compostable composite parts.”

Related Content

ZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.

Read MoreRunning shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreAviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreRead Next

Solico composite engineers bring comfort, flexibility to new Axile Bionics ankle prosthetic

Lunaris is Solico’s first medical prosthesis design, using advanced composite components to reduce weight and outer dimensions, and enhance wearability.

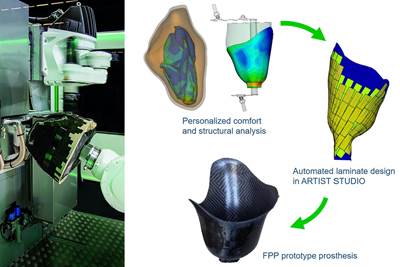

Read MoreCevotec’s fiber patch placement is part of digital process chain for automated composite prosthetics

Multiple partners work to develop automated data collection, composite laminate generation for customized medical applications using FPP technology in German-funded Patch2Patient project.

Read MoreFiber Institute Bremen develops high-strength PLA biopolymers

Novel PLA blend is proven on pilot plant scale for technical textile applications like aerospace, medical or automotive engineering.

Read More