Solico collaborates on composite creations in marine

Solico has been involved in numerous projects including the Vanquish 55 powerboat, Leonardo Yachts Eagle 46 and Ex-Core foam-filled door panel, providing composite engineering solutions in customer collaborations.

Vanquish 55 powerboat. Photo credit: Vanquish Yachts

Solico (Oosterhout, Netherlands), a composite engineering company, has been involved in numerous customer collaborations, including the Vanquish 55 powerboat, Leonardo Yachts Eagle 46 and Ex-Core foam-filled door panel. Solico provides custom engineering and manufacturing solutions for numerous customers in the maritime, architectural, defense and industrial sectors.

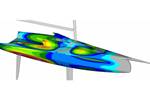

Solico Engineering collaborated on an engineering work package for the Vanquish 55 powerboat. Boasting a speed of up to 70 knots, the VQ55 Sports Line is said to be the first yacht of its size to be developed in a wind tunnel, enabling a vessel that outpaces other yachts in its category. Solico provided the finite element analysis (FEA) optimized engineering package for the hull, deck and swimming platform, customizing the ability for Vanquish to deliver a hull per month from its composite tooling.

Solico was also involved in the model development of the Eagle 46 yacht, which has been engineered to be built using flax materials. The sustainable vessel is meant to exemplify Solico’s commitment to eco-friendly engineering solutions. The flax-based construction offers a green alternative without compromising quality and performance, demonstrating the possibilities for sustainable innovation in the yachting industry.

Ex-Core has been used for several components in the Solico-engineered Wajer Yachts range. Originally developed by Donkervoort for automotive applications, Ex-Core is a versatile technology that uses synthetic foam technology to create carbon fiber parts by using the foam core to push the carbon skins against the mold surface. Operating almost in reverse to normal composites, the process enables cored seamless composite parts that offer weight reduction while also improving noise reduction and structural integrity.

Related Content

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

-

MerConcept, Extracthive integrate rCF components into racing yacht construction

Development and integration of recycled composite ballast dorade vents for an IMOCA class yacht and other ongoing projects demonstrate a push for greater circularity in the marine industry.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.