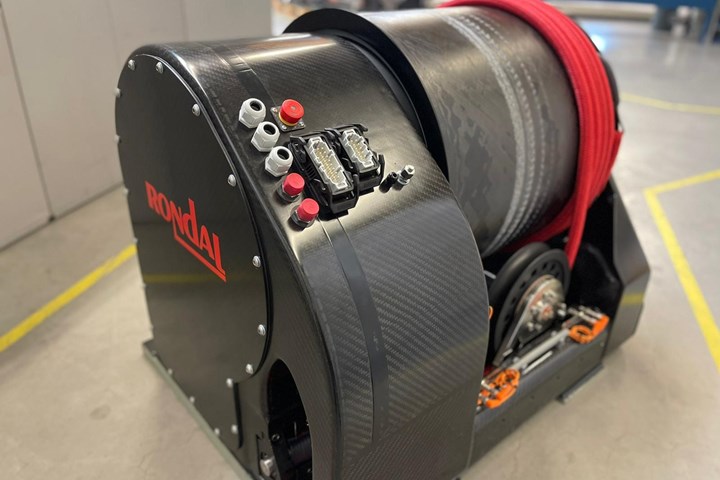

Solico, Rondal collaborate on an all-composite halyard winch

The winch is comprised of a carbon fiber prepreg winch housing and filament-wound carbon fiber winch drum which contributes to stability improvements and overall efficiency in marine applications.

Share

Read Next

Photo Credit: Solico Engineering, Rondal

Solico Engineering (Dubai, United Arab Emirates), a maritime composite engineering specialist, has collaborated with composite spar and component builder Rondal (Vollenhove, Netherlands) on a wide variety of engineering projects, including its most recent all-composite halyard winch.

The composite winch was designed for a nominal load of 18,000 kilograms (approx. 39,683 pounds), with three different sizes engineered by Solico. The company also completed finite element analysis (FEA), structural verification and laminate specifications for the carbon fiber prepreg winch housing and filament-wound carbon fiber winch drum. According to Solico, weight reduction in these highly loaded winch systems improves the overall efficiency of the sail handling package as well as contributing to stability improvements and allowing additional equipment to be carried onboard.

Solico is exhibiting at METS 2021, a trade exhibition of marine equipment, materials and systems, in Amsterdam from Nov. 16-18, 2021. The Solico stand will highlight the company’s full spectrum of composite engineering capabilities, focusing on sailing superyachts, motor superyachts, commercial marine craft and small boats. Also on display will be two of Solico’s most recent projects, the all-carbon fiber captive reel winch from Rondal, and a scale model of the new 30-foot Aeolos P30 carbon fiber race boat.

Related Content

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.