Solvay, Composites One enter Process Materials business negotiation

The PM business provides a broad array of vacuum bagging materials. The proposed transaction will enable Solvay to continue focusing on its core composites technology portfolio.

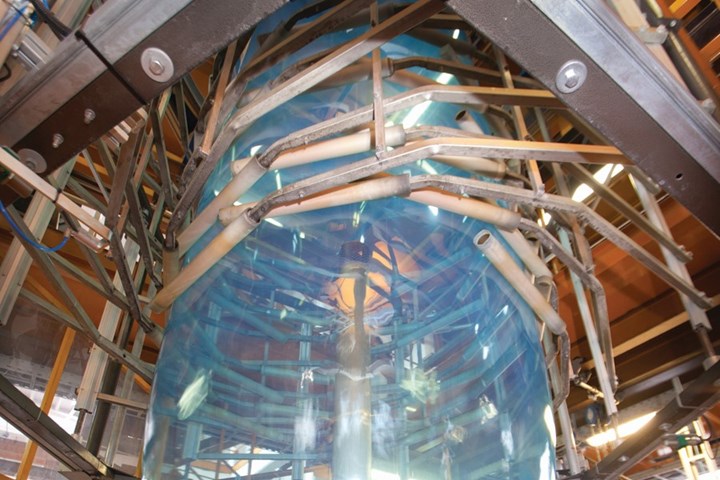

Photo Credit: Solvay

It was reported on Nov. 5 that Solvay (Alpharetta, Ga., U.S.) and Composites One (Arlington Heights, Ill., U.S.) have entered into an exclusive negotiation period for the acquisition of Solvay’s Process Materials (PM) business by Composites One. The PM business is said to provide a broad array of vacuum bagging materials including bagging films, breather fabrics, release films and

fabrics, peel plies, sealant tapes, plus valves and hoses. Additionally, the business is said to be a leader in the manufacture of tailored consumable kits and hard and soft tooling.

“Solvay has significantly strengthened the Process Materials business over the last several years. The proposed transaction will deliver value for our shareholders and enable Solvay to continue focusing on our core composites technology portfolio,” says Carmelo Lo Faro, president of Solvay Composite Materials Global business unit. “The Process Materials employees and customers will greatly benefit from this business being part of Composites One’s established and recognized distribution infrastructure. Composites One’s intent is to grow and invest in the business, fostering innovation, reliability and customer service and building on the excellent work our teammates have done so far.”

According to Composites One CEO, Steve Dehmlow, it has been a distributor for Solvay for more than two years and, from working closely with its leadership and team members, has seen Solvay’s focus on serving its customers. “The Process Materials business provides [will] us with a global connection to wind and aerospace customers,” he adds.

The completion of the transaction, expected early in the first quarter of 2021, would remain subject to following social processes and approval by the relevant regulatory authorities.

Related Content

-

Reducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

-

New online training course targets prepreg basics

JEC World 2024: Composites Expert highlights how its E-Learning Composites Academy platform supports flexible industry learning with new courses developed with Stelia Aerospace North America.

-

Daher inaugurates Learning Center for training aeronautical talent

Daher offers a concrete solution to the shortage of qualified professionals in aerospace, providing a range of technical programs that prepare workers for the sector’s rigorous demands.