Solvay, SGL to develop large-tow carbon fiber materials for aerostructures

The joint development agreement (JDA) intends to bring to market the first composite materials for commercial aerostructures based on large-tow intermediate modulus (IM) carbon fiber.

Carbon fiber production line at SGL Carbon’s multi-line facility in Moses Lake, Wash., U.S. The plant, originally established to make carbon fiber for BMW, produces 50k tow carbon fibers. Source: SGL Carbon. Source | SGL Carbon

Specialty chemicals giant Solvay (Brussels, Belgium) and carbon fiber manufacturer SGL Carbon (Wiesbaden, Germany) reported on Dec. 3 that they have entered into a joint development agreement (JDA) to bring to market the first composite materials based on large-tow intermediate modulus (IM) carbon fiber. These materials, which help address the need to reduce costs and CO2 emissions, and improve the production process and fuel efficiency of next-generation commercial aircraft, will be based on SGL Carbon’s large-tow IM carbon fiber and Solvay’s primary structure resin systems.

The agreement encompasses thermoset and thermoplastic composite technologies. It builds on Solvay’s position as a supplier of advanced materials to the aerospace industry and SGL Carbon’s expertise in high-volume carbon fiber manufacturing.

“For Solvay, this is an opportunity to lead the aerospace adoption of a composite material based on 50k IM carbon fiber. This is a highly competitive value proposition that brings more affordable high- performance solutions to our customers. We see this as the first step in a long-term partnership,” says Augusto Di Donfrancesco, member of Solvay’s executive committee.

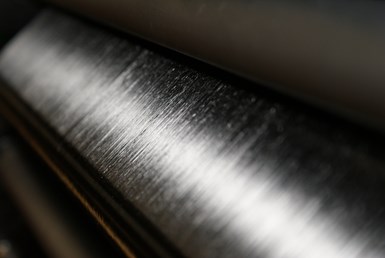

Closeup of SGL Carbon carbon fiber. Source | SGL Carbon

“By combining SGL’s carbon fiber expertise in our newly developed, unique 50k IM fiber with Solvay’s resin formulation and aerospace market expertise, both partners are aiming to develop an advanced aerospace material system. This alliance supports our strategic direction and accelerates our growth in the attractive aerospace market,” said Dr. Michael Majerus, spokesman of the management board of SGL Carbon.

Composite materials for aerospace applications represent a multi-billion-dollar market that is expected to grow strongly in the coming decade. Solvay and SGL Carbon are uniquely positioned to develop solutions to address the needs of this market.

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.