Tepex Dynalite backseat over 40% lighter than steel part

Continuous glass fiber layers designed to withstand bending and torsional stress.

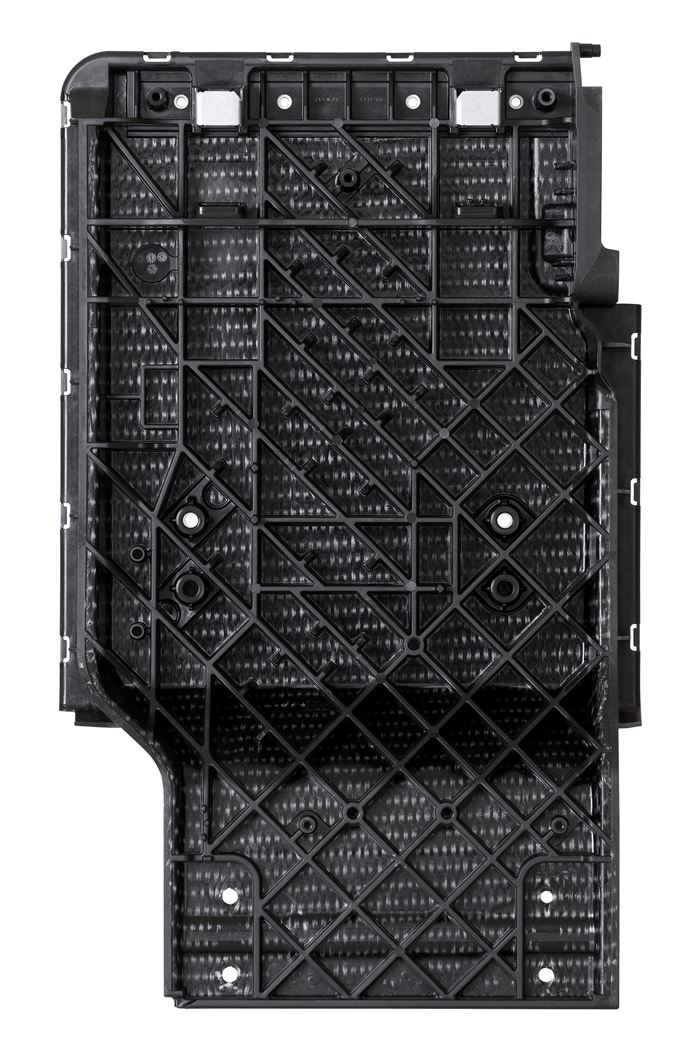

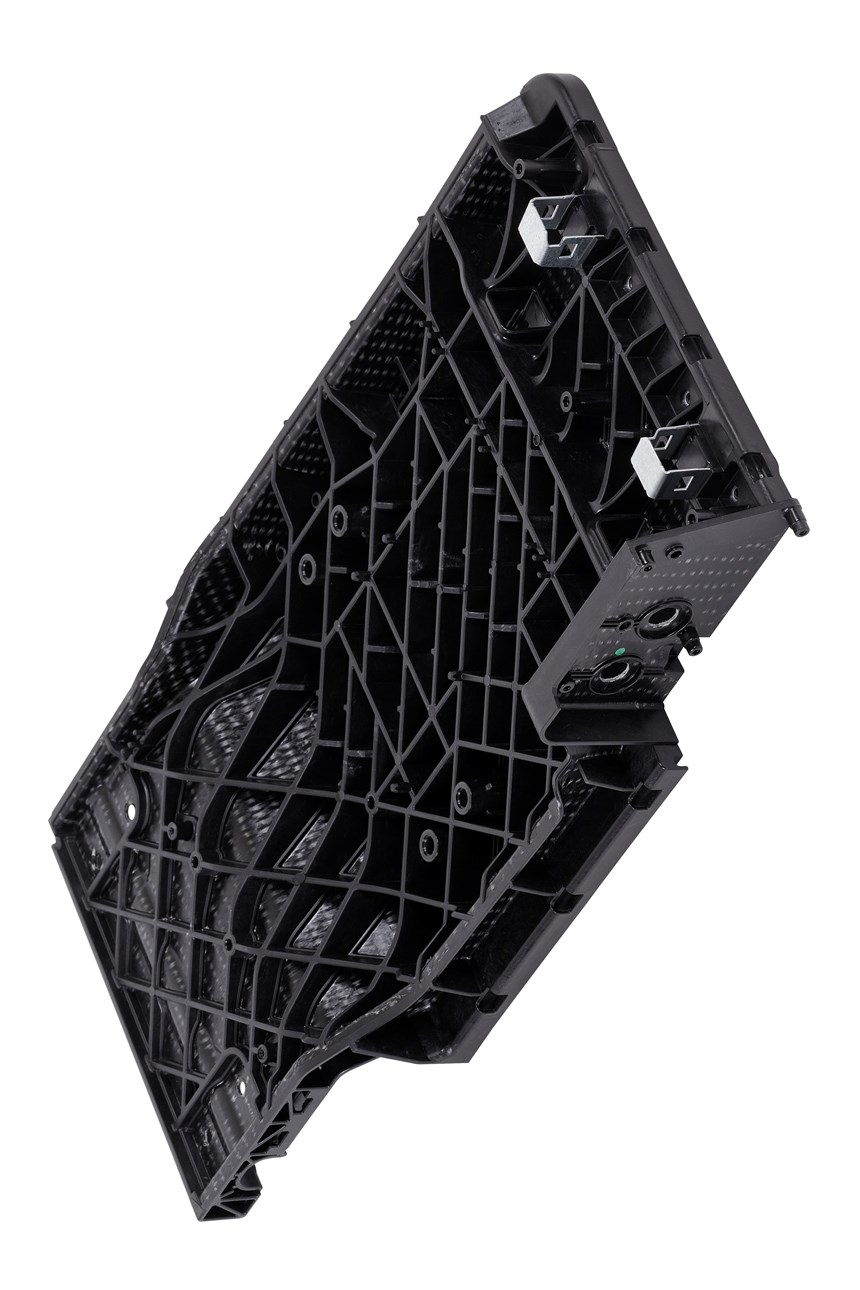

Lanxess Corp. says that its Tepex dynalite continuous-fiber-reinforced, semi-finished thermoplastic composites are now finding new applications in vehicle interiors. One example is the backseat system of an off-road vehicle made by a European automotive manufacturer. The center backseat is equipped with a load-through that enables the backrest of each seat to be folded down individually. This load-through component is produced by shaping and back-injecting Tepex dynalite. “The part marks the entry of this composite material into the lightweight design of backseat systems and is further evidence of its enormous potential in series production applications,” says Henrik Plaggenborg head of Technical Marketing & Business Development Tepex Automotive.

“The new component is more than 40 percent lighter than its steel counterpart. At the same time, this safety-relevant component withstands all load scenarios, because the orientation of the continuous fiber layers in the only two millimeter-thick semi-finished product is designed to bear the mechanical stress,” says Harri Dittmar, project manager and Tepex applications specialist. Tepex is manufactured by Lanxess subsidiary Bond-Laminates GmbH, which is based in Brilon, Germany.

The lightweight component was developed by Brose Fahrzeugteile GmbH & Co. KG with support from the Lanxess High Performance Materials business unit. Brose manufactures the component at its site in Coburg, Germany.

Strong in case of front and rear crashes

For functional reasons, the load-through is only mounted on one side, at the top of the rear seat’s backrest. Because of its position, it is exposed to both bending and torsion forces. To withstand these load scenarios, a special multiaxial design was chosen for the continuous-glass-fiber layers in the thermoplastic composite. Multiaxial Tepex is a new development from Bond-Laminates, which makes the composite sheets significantly stronger than before by combining the Tepex fabric with tapes in a technically complex process. The semi-finished product for the load-through has a core consisting of four layers, each 0.25 millimeters thick, which have a fiber orientation of +45 and -45 degrees relative to the component’s longitudinal axis and are arranged symmetrically. They absorb the torsion forces. In contrast, the bending forces are absorbed by the two outer layers, each 0.5 millimeters thick, in which 80 percent of the continuous fibers are in the direction of force. “In case of a frontal collision, this multiaxial layer design ensures that the lightweight component withstands the impact of the accelerated load in the trunk and, in case of a rear collision, the inertia forces pressing the passenger into the seat,” says Dittmar.

Efficient one-shot process

To manufacture the load-through, a blank of the semi-finished product is heated, placed in the injection mold, shaped and back-injected with a glass fiber-reinforced thermoplastic. In addition to ribbing that lends the part high stiffness, numerous functional elements are integrally molded on the component in the injection molding step, such as mounts for the headrest, various mounting points and screw connections, and the surrounding groove to which the rear, textile covering of the load-through is mounted. With a conventional steel design, this functional component would have had to be welded or screwed on separately.

Extensive HiAnt service for mold engineering

The mold for the load-through was optimized with the help of a draping simulation developed by Lanxess as part of its HiAnt services. Under this brand name, the company has combined its extensive range of services for supporting customers through the entire component engineering process. Various shaping strategies were visualized and evaluated in the draping simulation. The results were incorporated in mold design from the outset and helped to reduce the development time significantly. Lanxess derived the design of the semi-finished product blank on the basis of the specific mold technology. The blank is pre-shaped or locally held in place inside the mold before the mold is fully closed. “This prevents the formation of folds and the over-extension of the continuous fibers during shaping of the semi-finished product,” says Dittmar.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)