Teton Simulation joins Stratasys GrabCAD Software Partner Program

Teton’s SmartSlice software for plastics and polymers will be integrated with GrabCAD DFAM Software Development Kit for improved print parameter validation and optimization.

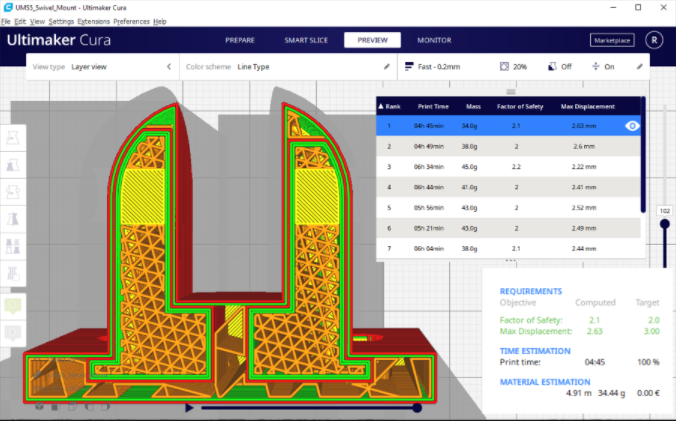

SmartSlice automatically generates multiple print configurations. Photo Credit: Teton Simulation

Teton Simulation (Layramie, Wyo., U.S.) has joined Stratasys Ltd.’s (Eden Prairie, Minn., U.S. and Rehovot, Israel) GrabCAD Software Partner Program, making Teton’s SmartSlice the first simulation 3D printing software to use the new GrabCAD DFAM Software Development Kit. The kit itself is said to help customers improve the reliability of additive manufacturing (AM) builds.

“Teton Simulation’s vision is to have SmartSlice offered to a multitude of customers within their software of choice. We have developed SmartSlice to be slicer agnostic, working with our hardware partners to integrate SmartSlice into their software offerings. Being able to validate as-printed performance, and minimize print times and material use all within the user’s current workflow is at the core of our strategy,” says Teton Simulation CEO Doug Kenik. “We are excited to announce that one of our next line of offerings outside of Ultimaker Cura will be with Stratasys, as their first “Design for Additive Manufacturing” Software Partner. Stratasys is the global leader in polymer AM, and we see a large opportunity to help their customers design better parts, faster using our SmartSlice technology within GrabCAD Print.”

According to Kenik, as AM continues to push into production workflows through machine and material innovations, software will help to drastically reduce cycle times and instill confidence that the printed part will function as desired. “Stratasys’ commitment to develop a software ecosystem which enables their customers to be successful is a signal that the market is ready, and that Teton Simulation’s SmartSlice is a key piece of technology to help push the industry forward,” he adds.

SmartSlice will be released as a plug-in to GrabCAD Print workflow software to make it easy to perform validation and optimization of print parameters for fused deposition modeling (FDM) 3D printing. The result, says Teton, is more confidence that parts meet functional and performance requirements, print as fast as possible and minimize material waste.

“Our focus is on making it easier for advanced manufacturing initiatives to integrate 3D printing on the factory floor for maximum productivity,” says Paul Giaconia, vice president of software products for Stratasys. “One of the keys to scaling 3D printing into production is to make it easy for engineers and designers to create and validate digital product designs using their CAD and simulation tools where AM could provide the best solution. Adding Teton Simulation integrated with GrabCAD Print directly solves the design-for-additive-manufacturing challenge.”

Related Content

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

.jpg;maxWidth=300;quality=90)