The NCC, Skanska trial low-carbon, basalt fiber-reinforced concrete

Study is critical to understanding the impact of low-carbon concrete and advanced composite reinforcement systems in the construction sector, and its contributions toward low-carbon emissions, structural performance and EOL recycling.

Under a £282 million (~$381 million) project, the National Composites Center (NCC, Bristol, U.K.) and construction company Skansa (Stockholm, Sweden) are trialing an “industry-first” low-carbon concrete with basalt fiber reinforcement, designed to alleviate congestion for motorists on National Highways M42 Junction 6, a temporary haul road for construction vehicles and a well-known bottleneck in the Midlands. While aiming to cut down on carbon emissions — a combination that is reported to reduce the carbon footprint by more than 50% — the project also serves to improve the structural performance of reinforced concrete and deliver better productivity, safety and cost outcomes.

The trial, led by Skanska, in partnership with the NCC and funded by National Highways (NH), compares traditional steel-reinforced concrete with a low-carbon concrete reinforced with basalt fiber.

Production of cement, a key ingredient in concrete, currently accounts for around 7% of the world’s CO2 emissions. In the U.K., this figure is less than 1.5% as a result of innovation and investment in efficient plant, fuel switching and the use of low-carbon cement substitutes that are byproducts from other industries.

Tarmac (Solihull, U.K.), a member of the project’s supply chain, provided two types of concrete for the trial: A mix comprising conventional blended cementitious material and a low-carbon alternative mix incorporating an Alkali Activated Cementitious Material (AACM) in place of the cement.

“Manufactured at a conventional concrete plant located close to the project and installed in exactly the same way as traditional materials, this new sustainable product delivers a carbon footprint up to 80% lower than a standard CEM I concrete,” claims Robert Gossling, head of commercial engineering for Tarmac. “We hope this demonstration will help to accelerate the development of innovative low-carbon materials.”

Photo Credit: The NCC

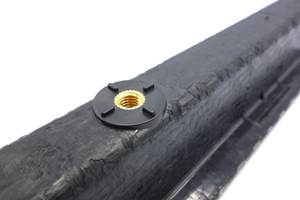

Basalt Technologies UK Ltd. (London, U.K.) supplied the basalt fiber reinforcement. “Basalt is a lightweight composite material consuming 62% less CO2 than steel during its manufacture,” says Malcolm Newton, director at Basalt Technologies. “It comprises a nonmetallic inert material that does not corrode, making it more durable than steel. Basalt fiber reinforcement is also up to four to five times lighter than steel, making it safer to handle, fix and transport with fewer lorry movements.”

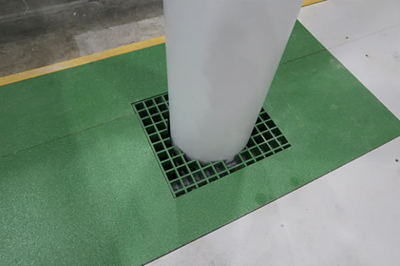

Field and laboratory tests will be carried out over the coming months following the start of the trial, which began early Dec 2021. Four reinforced concrete slabs were cast at the M42 Junction 6 site as part of a temporary haul road that will be heavily used by construction vehicles and will be monitored over the works duration. The slabs comprise of:

- Slab A: Conventional concrete + steel reinforcement

- Slab B: Low-carbon concrete + steel reinforcement

- Slab C: Conventional concrete + basalt reinforcement

- Slab D: Low carbon concrete + basalt reinforcement

The team is now monitoring the slabs in-situ. Full-scale test slabs have been sent to a specialist laboratory for bending and shear testing. All collected test results will build knowledge of the curing process, ease of construction, safety benefits, functional properties and structural behavior of the various concrete and reinforcement combinations. This will provide insight into the future use of longer lasting materials in construction.

The trial will also provide a better understanding of the impact of the use of these materials ahead of the proposed revision to Eurocode 2 standards that will include use of composites in the design of concrete structures. This is currently being developed.

“This project, its learnings and test results, is critical to understanding the impact of low-carbon concrete and advanced composite reinforcement systems to reduce embodied carbon for the construction sector,” adds Carys Holloway, technology program manager, NCC. “I am eager to witness the expected ease of planing out of the basalt fiber-reinforced slabs for recycling and the potential that has for end-of-life [EOL] scenarios.”

The Skanska and NCC team will also be working with HS2 to further research and develop this innovative low-carbon solution. Work on the M42 junction upgrade is set to be complete 2024-2025.

Related Content

Melker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.

Read MoreRobotized system makes overmolding mobile, flexible

Anybrid’s ROBIN demonstrates inline/offline functionalization of profiles, 3D-printed panels and bio-based materials for more efficient, sustainable composite parts.

Read MoreLingrove plant-based ekoa composite featured in Hyundai Palisade concept vehicle

Carbon-neutral biocomposite enables interactive doorspear with look and feel of wood while protecting trees, enabling transparency and capacitive touch for futuretech.

Read MoreNASCAR unveils BEV prototype featuring natural fiber bodywork

Implementation of Bcomp technical flax fibers in a U.S. motorsport first represents NASCAR’s step toward more sustainable competition vehicles.

Read MoreRead Next

Dura Composites, Anderton Concrete provide single-source access to concrete trenching, GRP lid solutions

U.K. energy and infrastructure customers gain technical engineering support and local supply of durable precast concrete trenches and pultruded GRP trough lid offerings.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)