Dura Composites, Anderton Concrete provide single-source access to concrete trenching, GRP lid solutions

U.K. energy and infrastructure customers gain technical engineering support and local supply of durable precast concrete trenches and pultruded GRP trough lid offerings.

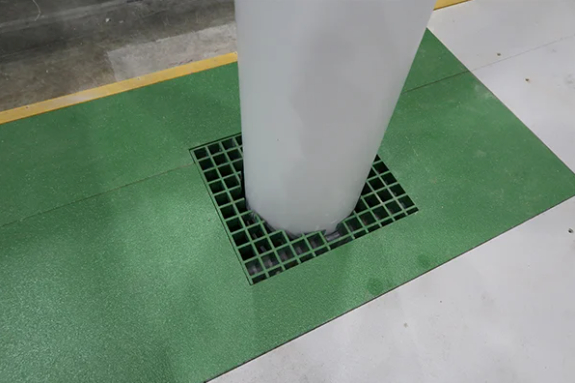

Photo Credit: Dura Composites

Having previously worked together on several successful projects, Dura Composites (Essex, U.K.) and Anderton Concrete (Northwich, U.K.) are now teaming up to help U.K. energy and infrastructure customers access precast concrete troughs and pultruded glass fiber-reinforced polymer (GRP) composite trench covers from a locally available single supply chain source partner alongside local technical engineering support.

Through this partnership, Anderton Concrete, known its manufacture of rail and structural precast concrete products, is also enhancing its offering of precast-reinforced concrete troughs to include solutions specifically designed for these targeted sectors, such as lightweight and non-conductive GRP trough lids — including molded open mesh Dura Grating for pedestrian loadings and solid pultruded Dura Slab lids for vehicular loadings.

The collaboration will also help Dura Composites deliver on its ambition to make the use of composite products mainstream and is the latest in a series of major developments for the company, which recently won its second Queen’s Award for Enterprise.

“Dura Composites’ goal of unlocking the power of composites for the energy sector builds on our core mission of combining innovative products with unique manufacturing methods to deliver the safest, most cost-effective and durable solutions on the market [see “Dura Composites appoints new United Arab Emirates GRP distributor”],” says Joe Hunt, industrial sales manager at Dura Composites. “Our partnership with Anderton Concrete will enable both partners to apply our unique knowledge and skillsets to supply combined trough and lid solutions that solve the core challenges the industry has been experiencing for years. Anderton Concrete’s existing customer base will also be able to benefit from Dura Composites’ high U.K. stock holding, technical support and structural design services to deliver tangible added value.”

With more than a decade of experience in supplying specialist GRP composites to the energy sector, Dura Composites says it has seen a marked increase in customers requiring a combined concrete trough and GRP lid system. GRP lids enable easy manual handling, simple installation on site and have a gritted anti-slip surface that requires minimal maintenance. Dura Composites’ GRP lids can also be fitted with a mechanical lifting system, eliminating the need for heavy plant machinery while ensuring accessible inspection.

Crucially, Dura Composites’ GRP trench covers have undergone extensive testing using UKAS (the National Accreditation Body for the United Kingdom) accredited laboratories to comply with BS EN 124 and FACTA requirements, as well as a wealth of supplementary in-house testing, using a fully calibrated test facility.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.