Thermwood developing large-scale additive manufacturing system

The large-format additive manufacturing machine will produce near net shape parts up to 10 by 10 by 5 ft and provide post-process machining and trimming functions as well.

Thermwood Corp. (Dale, IN, US), a manufacturer of CNC routers, has embarked on a program to develop Large Scale Additive Manufacturing (LSAM), which can perform additive and subtractive functions on the same machine. This near net shape approach uses a high-volume thermoplastic printer to quickly create a part that is nearly, but not exactly, the final net shape. A subtractive function then machines the part to the exact final net shape.

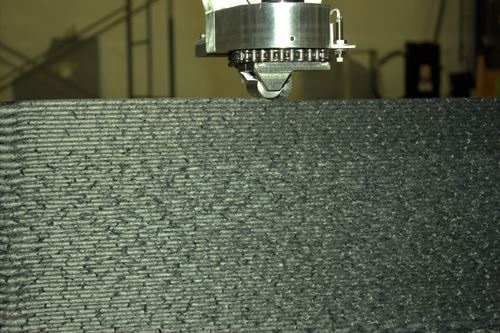

Thermwood says its development system has performed well during initial additive testing, including initial validation of an all-new MeltShape Technology. Melt shaping promises enhanced control of layer shape and improved bonding between layers. This new patent-pending approach uses one or more shaping wheels to shape, form and compress the hot plastic melt as it is extruded, insuring that each new layer is the proper shape and thickness, and that it bonds firmly to previously applied material.

Kevin Slusarz, American Kuhne vice president of process technology, assisted with the startup effort. American Kuhne, a Graham Group Co., supplied the custom extrusion system for Thermwood’s development machine. The extrusion system performed flawlessly during initial testing. Extruder controls are designed to smoothly network and integrate with the machine control. “We are quite pleased to have a partner like American Kuhne as part of this development program,” says Ken Susnjara, Thermwood’s CEO.

The material processed during startup testing was a 20% carbon graphite-filled ABS from Techmer ES. Thermwood is in discussions with other material supplier to test their material in this new application.

Thermwood’s melt shaping approach to adding material offers several significant advantages. Because layers are rolled together, rather than tamped together, air between layers is squeezed out during the additive process, so it is much less likely that air becomes trapped between layers. This was borne out during initial testing which, says Thermwood, produced virtually void-free walls. This addresses the problem of trapped air delaminating layers when a part is processed through a heated autoclave, which is a common requirement for aerospace parts and patterns.

This approach uses a melt-shaping wheel that interacts with the extruded thermoplastic bead while it is still hot and pliable. The shaping wheel is servo-controlled so it can track the direction of machine motion. The Thermwood machine is a full 6-axis system — five axes to position the head in any orientation and the sixth axis to align the shaping wheels to the machine motion direction. Thermwood has added a software feature to its Q Core CNC control called Tangential Following, which automatically keeps the shaping wheel aligned with the direction of machine motion without the need for 6-axis programming. This eliminates the need for a specialized CAD/CAM system to handle the sixth axis and allows the use of virtually any 5-axis CAD/CAM system to program machine motion.

Thermwood envisions different shaping wheels, each imparting specific characteristics to the hot plastic bead. Because of its 5-axis head configuration, material can be applied at an angle or onto a curved surfaces in addition to traditional horizontal layers. This capability opens new processing possibilities and supports free form additive manufacturing techniques not currently possible. Thermwood’s initial test machine, which can print parts up to 10 by 10 by 5 ft thick, is expected to be fitted with a 5-axis subtractive gantry trim system in the next few months, at which time all functions can be performed on the same machine.

Thermwood plans to continue this development effort with the goal of offering these machines in a variety of large sizes for commercial applications. Management cannot yet determine when the technology might be sufficiently refined for commercial rather than purely research and development applications. In the meantime Thermwood plans to continue working with material vendors, R&D operations and potential users in an ongoing development effort.

Related Content

From the CW Archives: Drilling is not for the faint of heart

This edition of From the CW Archives revisits CW’s first plant tour — a visit to the F-35 FAL in Fort Worth, Texas — and a story by Ginger Gardiner a few years later. Both offer lessons on how to perform stacked drilling through composite and metallic materials.

Read MoreBelotti, Cosberg partner for advanced automated assembly solutions

The Italy-based companies merge technological know-how to develop novel systems for the processing and assembly of light alloys and carbon fiber components.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreAI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpeg;maxWidth=300;quality=70)