UAC and COMAC approved the general layout of CR929 next new wide-body aircraft

UAC and COMAC have agreed to the aircraft’s principal geometry and will next move on to the stage of full-scale joint development of the aircraft design and systems.

United Aircraft Corporation (PJSC UAC, Moscow, Russia) and Commercial Aircraft Corporation of China (COMAC, Shanghai) approved the general layout of CR929 long-range wide-body aircraft. The CR929 will reportedly seat 280 and have a range of up to 12,000 kilometers. It will be assembled in Shanghai and its maiden flight is scheduled for 2025 and with deliveries beginning in 2028.

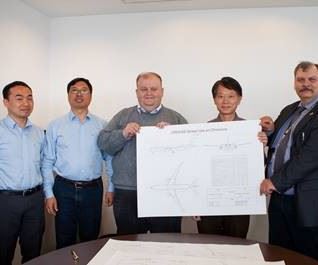

UAC and COMAC have agreed to the aircraft’s principal geometry – wing span and shape, fuselage length, fuselage nose and tail section dimensions, aircraft fins sizing and form, location of engines, landing gear and doors. This is a result of efforts undertaken by JET-team, the joint Sino-Russian engineering team headed by CR929 chief designers Maxim Litvinov (representing the Russian side) and Chen Yingchun (representing the Chinese side).

As explained by Litvinov at the CR929 general layout signing ceremony, “The parties’ approval of CR929 general layout is a major step forward towards subsequent development of a uniform technical concept of CR929 family aircraft. This allows us to move on to the stage of full-scale joint development of the aircraft design and systems, inter alia, in the context of liaising with the potential suppliers of aircraft equipment and components.”

Yingchun congratulated the team of Russian and Chinese engineers and noted the importance of CR929 general layout approval for further work to be carried out under the program.

The CR929 Program is currently at Gate 3 phase. Apart from aircraft general layout approval, this stage also includes experimental research work in the sphere of aerodynamics, selection of structural materials and analysis of technical commercial proposals submitted by potential suppliers of the key systems and equipment. These works and Gate 3 phase are expected to be completed by mid-2019.

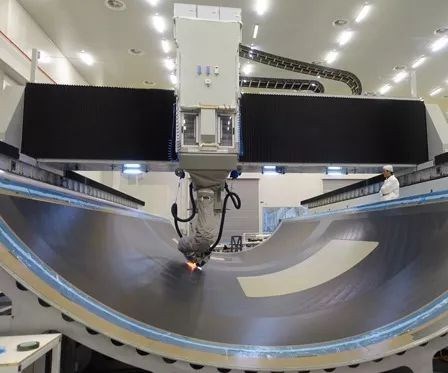

According to a Jan 2018 article by reporter Yang Jian on Shine.cn and COMAC America Corp. on Twitter, full-size composite fuselage panels were completed using automated fiber placement/tape laying:

“A major milestone in the #CR929 program as manufacturing tests of full-scale 15 x 6 meter composite fuselage panels were successfully completed, with follow-up tests showing good results. These composite components will enable the CR929 to reduce weight and increase efficiency.”

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.