UMaine Composites Center receives $500,000 to help boat builders incorporate 3D printing technology

Technology cluster will help Maine boatbuilders explore how large-scale 3D printing with wood plastic composites can provide a competitive advantage.

Share

Read Next

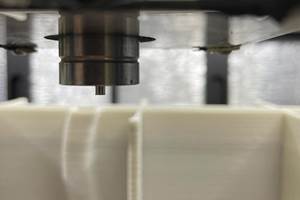

The University of Maine Advanced Structures and Composites Center (Orono, ME, US) has received $500,000 from the Maine Technology Institute (MTI) to form a technology cluster to help Maine boatbuilders explore how large-scale 3D printing using economical, wood plastic composites (WPCs) can provide the industry with a competitive advantage. WPCs are composite materials made of thermoplastic polymers (e.g., PE, PP, PVC, PLA) reinforced with wood fiber and/or wood flour. The WPC markest is estimated to be worth $1-10 billion annually by the next decade.

This technology cluster brings together the expertise of UMaine researchers and marine industry leaders to further develop and commercialize 3D printing (also known as additive manufacturing) to benefit boatbuilders in the state.

Small to medium boatbuilders are often challenged by the cost and lead time required to create traditional marine tools and boat molds. 3D printing can help reduce the production time needed to fabricate boat molds by as much as 75% according to UMaine Composites Centero researchers.

However, widespread adoption of large-scale additive manufacturing has been tempered by the high cost of the 3D printers and feedstock materials. To address this, the UMaine Composites Center will develop a range of economical wood-filled materials for composite tooling applications. The use of the wood-based fillers significantly reduces the cost and increases the stiffness and toughness of the material, while reducing the environmental impact and improving recyclability.

“The combination of additive manufacturing and cost-effective, bio-filled materials is a potential game-changer for Maine’s boatbuilding industry by reducing the cost of marine tooling by as much as 50 percent,” says James Anderson, senior research and development program manager at the UMaine Composites Center. “Maine boatbuilders cannot absorb the cost of acquiring a large-scale 3D printer and testing new feedstock materials. The UMaine Composites Center and the Maine boatbuilding industry share a tradition of innovation. We have the tools and knowledge to help Maine boatbuilders increase productivity, reduce costs and, ultimately, continue their tradition of excellence in the boatbuilding industry.”

“For the past 18 years, the UMaine Composites Center has been developing technologies to extrude plastics filled with wood cellulose and nanocellulose fibers. These plastics contain up to 50 percent wood fiber by weight,” says Habib Dagher, executive director of the UMaine Composites Center.

“Now, we will use these same stronger and stiffer plastics in very large 3D printers to develop 20- to 100-foot boat molds and other boat parts for Maine boatbuilders. By 3D printing plastics with 50 percent wood, we aim to produce boat molds much faster and cheaper than today’s traditional methods. As we learn, we will be working with boatbuilders to incorporate 3D printing in their production process for larger boat parts and, eventually, the boats themselves.”

Boatbuilding isn’t the only industry expected to benefit from UMaine’s research and development. The university is working with Maine-based companies to develop a local supply chain for its unique, bio-filled materials.

The $500,000 grant from MTI will be matched with $500,000 from the U.S. Army Natick Soldier Research, Development & Engineering Center to form a technology cluster of UMaine engineers and researchers with Maine boatbuilders, including Custom Composite Technologies in Bath, Compounding Solutions in Lewiston, Back Cove Yachts in Rockland, Sabre Yachts in Raymond, Front Street Shipyard in Belfast, Hinckley Yachts in Trenton, Hodgdon Yachts in Boothbay, Kenway Composites in Augusta and Lyman-Morse Boatbuilding in Rockland.

The consortium will work to design and print marine tools and boat molds for testing and evaluation, and develop a 3D printing training course for boatbuilders, as part of the adoption and commercialization process.

Related Content

Plant tour: Airtech International, Springfield, Tenn., U.S.

Fifty years of supplying materials for composites manufacturing includes custom fabrication and now aims to advance 3D-printed tooling, parts and new resins.

Read MoreMold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreFyous launches infinitely reusable manufacturing mold tech

PolyMorphic Moulding technology uses 28,000 digitally controlled pins to create a shape from a 3D CAD shape in less than 20 minutes, achieving zero waste and enabling parts production 14 times faster than 3D printing.

Read MoreProper application of semi-permanent mold release systems

Performing regular maintenance of the layup tool for successful sealing and release is required to reduce the risk of part adherence.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)