Voith unveils digital carbon fiber manufacturing line

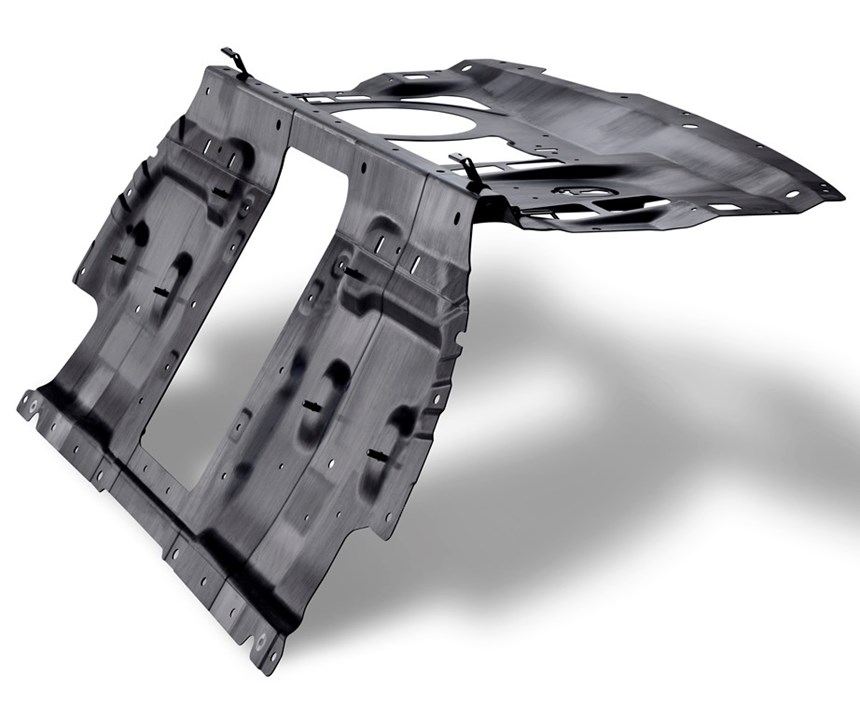

Patented production line used to produce the carbon fiber reinforced plastic rear panel for the new Audi A8.

Voith (Heidenheim, Germany) introduced its new carbon fiber manufacturing line at JEC World 2018, the world’s leading trade show for fiber-reinforced components. With this new line, Voith continues to grow in the automotive and aerospace markets with the production of carbon composite components.

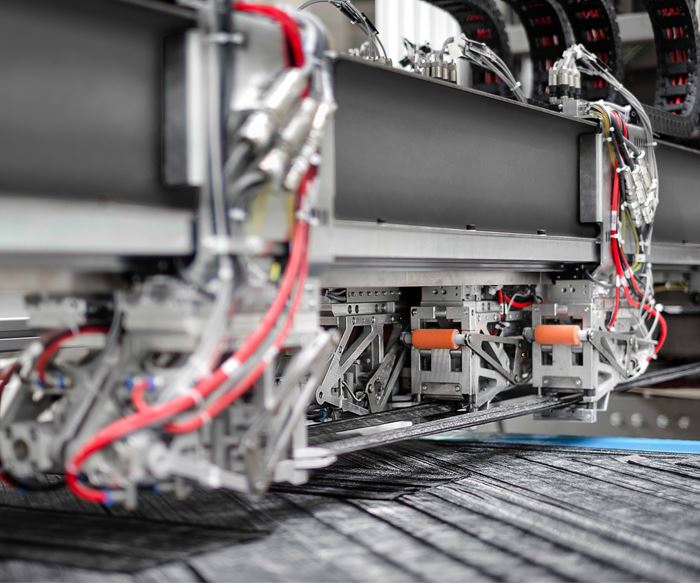

The patented Voith Roving Applicator (VRA) is the core and one of the main parts of this state-of- the-art production line producing the CFRP rear panel for the new Audi A8. This high-load structural component has a complex carbon fiber structure with local reinforcements and is produced using direct fiber placement technology.

In this context, robust preforming without gaps and creases is crucial to meet the stringent quality and cycle time requirements. Voith developed a new, highly efficient forming simulation method to enable the required segmented stamp forming process, which follows the innovative VRA fiber placement process.

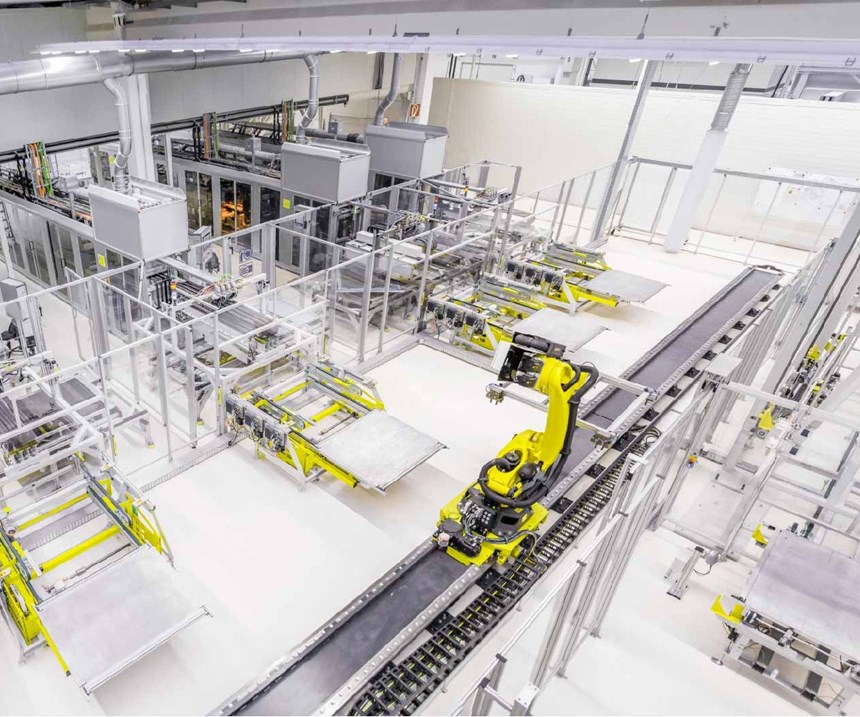

After the preforming, a high-pressure resin transfer molding (HP-RTM) process is used to inject the matrix through the fiber material. Subsequently the parts are trimmed by a milling process, a machine washing and fully automated assembly with metallic subcomponents. The transport between the single process steps is done by robotic systems, leading to a new level of production automation of composite components.

“With a whole new digital 4.0 production line, we are setting new standards producing carbon fiber parts for high-volume automotive serial production,” says Voith Composites managing director Dr. Lars Herbeck. “Our smart factory concept allows the automated production of CFRP components in almost any shape and individual lot sizes.”

The high-volume CFRP production line of the Audi A8 rear wall module won the JEC Innovation Award 2018. Audi, together with Voith, DOW Automotive, and Zoltek Corp. applied for this award in the category “Automotive Process. The foundations for this large-scale production were laid by the development partnership between Voith Composites and the automobile manufacturer Audi, which has been in place since 2011.

Related Content

-

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.