Voxelfill process presented by AIM3D overcomes inhomogeneous strength properties in 3D printing

Through the Voxelfill approach, components are 3D-printed via cross-layer filling versus layered printing, strengthening Z-direction weakness for materials like fiber-reinforced composites.

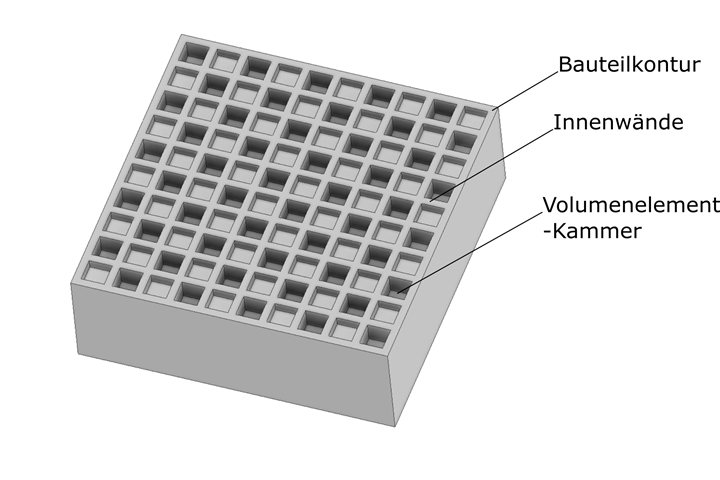

With the Voxelfill strategy, voxel cavities (component contour and inner walls) are printed and then selectively filled with material. (Bauteilkontur – Component contour; Innenwände – Inner walls; Volumenelementkammer – Volume element chamber). Photo Credit: AIM3D

AIM3D GmbH (Rostock, Germany) a spin-off company from the University of Rostock, presents the patent-pending Voxelfill process, which is able to overcome inhomogeneous strength issues of polymers inherent to layer-based 3D build processes by achieving defined, selective densities in the component.

According to the company, typical inhomogeneous strength properties primarily manifest themselves in the form of tensile and flexural strength shortcomings, as well as very brittle behavior along the Z-axis. In contrast, the strengths achieved along the X and Y axes with some processes are already close to the strengths possible with conventional injection molding — AIM3D has already demonstrated this with the processing of fiber-filled components based on PA6 GF30 materials. Resolving the inhomogeneous strength properties phenomenon will reportedly enable a wider applicability of 3D-printed components.

Using 3D extrusion technology in the composite extrusion modeling (CEM) process, AIM3D developed a Voxelfill strategy that is said to overcome these limitations and increases the cost-effectiveness of the CEM process. Voxelfill can also be used for multi-material components and is suitable for constructing 3D components using plastics, metals and ceramics.

Through the Voxelfill approach, components are no longer created exclusively in layers (i.e., 2.5D), but instead apply cross-layer filling by using so-called “voxels” as volume areas. To do this, the component contour is first created as the basic structure using one or more webs of the extruded material. A lattice pattern is created inside the component, which defines the boundaries of the volume elements to be filled, similar to cavities. This voxels structure to be filled resembles the honeycomb in a beehive.

The Voxelfill strategy comprises two process stages:

- (1) Generation of a lattice structure: The CEM system repeats this structure up to a defined height of the volume elements. Then, the previously created cavities (voxels) are filled by injecting thermoplastic material with the extruder.

- (2) Filling phase of the voxels: When the volume areas are filled, this does not include filling all voxels in one plane. This would again result in a Z-direction weakness directly in the “seam” plane. By shifting the volume elements halfway up the voxel, a kind of “brick-like bond” is created in the component, resulting in the yield line being offset. This results in a large increase in strength and also improves the elasticity of the components in the Z-direction. In addition, the introduced volume elements reduce the printing time for fully filled components and thus significantly increases the cost-effectiveness of the CEM process.

According to AIM3D, variations of the Voxelfill strategy with the CEM process enable the use of various materials — hybrid multi-material solutions with different Voxelfill materials and different materials for the contour/structure of the inner walls become possible. This way, the material properties can be “customized,” AIM3D says. Defined component weight, damping properties, elasticity or changes to the center of gravity can be tailored to the application. By selectively filling only certain volume chambers (selective densities), component properties could be influenced in a targeted manner on the basis of finite element (FE) simulations.

Moreover, using Voxelfill, it is possible to only fill the areas of a component that are absolutely necessary for the flow of forces. As a result, the components’ exteriors are said to look like conventional parts, and can also benefit from applying finishing processes. At the same time, however, the 3D printing process is carried out with reduced material and weight, right up to realizing lightweight components. Especially when deploying fiber-reinforced materials, the use of Voxelfill offers an additional option for specifically aligning the fiber in the component to enhance mechanical properties. In the flat plane, the CEM process is already said to offer options for controlling the fiber orientation. With the Voxelfill strategy, this affects the contour and the inner walls of the component. By injecting the material into the volume chambers (filling the voxels), the 3D component also receives fibers that are aligned in the Z-axis, thereby further improving mechanical properties.

“Of course, the Voxelfill process is particularly suitable for 3D printing of plastics and fiber-filled plastics, but it is also suitable for 3D printing of metal and ceramic components using the CEM process,” Clemens Lieberwirth, CTO at AIM3D, notes. “In general, there are advantages due to the higher build speed and cross-layer filling.”

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreRead Next

AIM3D multi-material 3D printer targets precise, cost-effective polymer processing

Extrusion 3D printer offers considerably faster build rates and can print up to three different materials in parallel for metals, ceramics and high-temperature plastics such as PEEK and PPS with or without fiber filling.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)