Wichita, Mississippi State request industry feedback and participation in advanced materials survey

Research program under the FAA ASSURE Center of Excellence to identify, assess and understand composites and advanced material systems used in unmanned aircraft systems and advanced air mobility designs.

Share

Read Next

Photo Credit: Wichita State University (WSU)

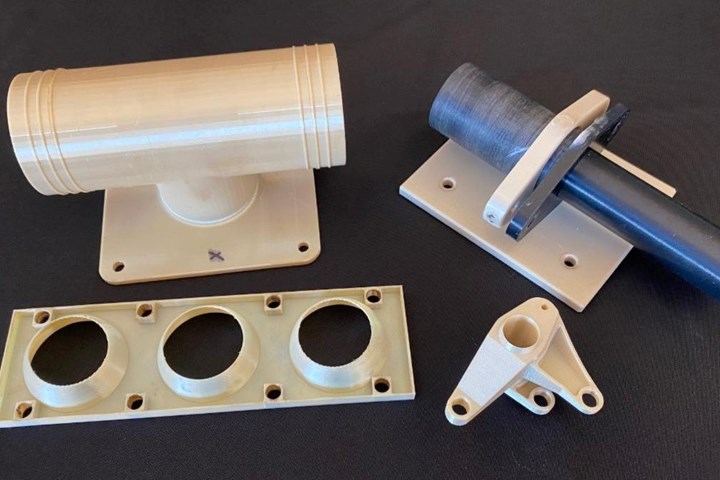

Wichita State University (WSU, Kan., U.S.) and Mississippi State University (MSU, Starkville, U.S.), part of the FAA ASSURE Center of Excellence, are currently working on a research project, to identify, assess and understand the varying types of composites and other advanced materials, as well as the additive manufacturing (AM) process, used in the construction of current and future unmanned aircraft systems (UAS) and advanced air mobility (AAM) aircraft.

The research program aims to identify the major differences between the use and application of advanced materials in UAS/AAM vehicles compared to traditional materials and manufacturing methods in 14 CFR Part 23,25,27 aircraft. For example, current certification guidelines developed by the FAA are typically intended for traditional continuous fiber-reinforced thermosetting composite materials and may not be appropriate for novel UAS and AAM advanced materials. Therefore, identifying these new material systems and manufacturing methods would help define future certification requirements.

WSU and MSU teams will conduct an extensive literature review and an industry-based survey addressing the above statements to collect the data necessary to support the research effort. Due to the novel and rapid technological advancements in the UAS and AAM community with limited information available in the open literature, there is a need for industry collaboration to help answer some of the primary research questions for this research program. This collaboration will be beneficial to the industry since it will help establish the foundation for future research efforts and certification guidelines as UAS and AAM vehicles are being designed with new advanced material types and manufacturing methods.

This collaboration will help FAA and industry by identifying technical gaps in the current standard methods on the qualification and certification of advanced material systems. In addition, this data will help the FAA define future certification requirements for AAM and UAS vehicle manufacturers.

The survey will be conducted using a market engagement software called New Product Blueprinting and is intended to take 1-1.5 hours to complete. It does not seek proprietary information, the data obtained will be kept confidential and only material types and manufacturing methods will be associated with generic AAM or UAS classes. In addition, the acquired information will not be tied to a specific company or individual.

If you are able to participate, please complete the form to receive additional information. WSU and MSU research teams would like to thank you in advance for your help and participation in this survey.

For questions or additional information, contact Luis Gomez or Matthew Roberson.

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

.jpg;maxWidth=300;quality=90)