ZeroAvia makes strides in hydrogen refueling via Shell collaboration, airport pipeline launch

Compressed, low-carbon hydrogen supply to be developed for ZeroAvia’s California facilities and power flight testing, leads to unveiling of 100-meter landside-to-airside hydrogen airport pipeline.

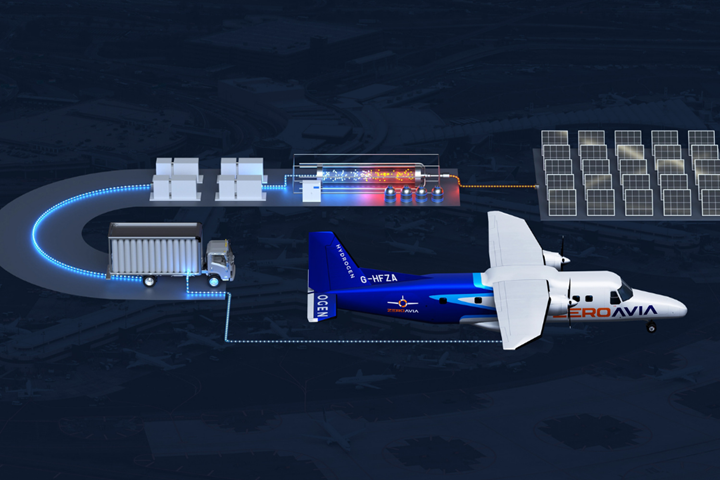

An example of ZeroAvia's hydrogen airport refuelling ecosystem (HARE). Photo Credit, all images: ZeroAvia

ZeroAvia (Hollister, Calif., U.S. and Kemble, U.K.) has announced a collaboration with its strategic investor, Shell (London, U.K.), which will design and build two commercial-scale mobile refuelers for use at ZeroAvia’s research and development (R&D) site in Hollister, Calif. The announcement follows recent positive predictions relating to the falling price trajectory of hydrogen fuel and a flurry of state-led activity for establishing H2 Hubs as the Department of Energy (DOE) prepares to receive bids from across the U.S.

At ZeroAvia’s test facility, Shell will also provide compressed, low-carbon hydrogen supply to the facility and other locations in the western U.S. This strategic collaboration will support the development of ZeroAvia’s flight testing program in the U.S. following the arrival of its second Dornier 228 at Hollister and will reportedly advance the company’s Hydrogen Airport Refueling Ecosystem (HARE) on a larger scale.

“Shell recognizes the aviation sector has unique challenges in decarbonization and needs practical and scalable net-zero solutions,” Oliver Bishop, general manager, hydrogen at Shell, says. “We believe ZeroAvia’s technology is a viable option, and this agreement will allow us to demonstrate successful provision of low-carbon hydrogen supply while supporting development of codes, standards and refueling protocols for hydrogen-powered aviation.”

The deal with Shell comes as ZeroAvia also unveils what is says is Europe’s first landside-to-airside hydrogen airport pipeline. The 100-meter-long hydrogen pipeline runs alongside ZeroAvia’s hangar at Cotswold Airport in the U.K. The company will use it alongside an electrolyzer and mobile refueler to use low-carbon hydrogen for its test flight program. The pipeline will help ZeroAvia demonstrate and explore the operational safety case for hydrogen pipelines and refueling infrastructure at airports.

ZeroAvia received support for the pipeline from the UK Government’s Department for Transport and the Connected Places Catapult as part of the Zero Emission Flight Infrastructure (ZEFI) program to enable airports and airfields to prepare for the future of zero-emission operations.

Both projects also enable ZeroAvia to further explore the connection between aircraft refueling and landside hydrogen use cases, such as road transport. ZeroAvia operates multiple hydrogen fuel cell road vehicles as part of its operations at Cotswold Airport and Hollister, demonstrating the potential for airports to act as hydrogen hubs for onward transport and ground operations.

“These milestone announcements represent significant hydrogen infrastructure advancement for ZeroAvia and the industry,” Arnab Chatterjee, VP infrastructure, ZeroAvia, notes. “Hydrogen-electric aviation is the only practical, holistic and economically attractive solution to aviation’s growing climate change impact. Fuel provision needs to be economical and convenient for airlines to achieve operational cost benefits.”

The company says it has also been working alongside the Department for Transport and Connected Places Catapult on a concept study for liquid hydrogen mobile refueling vehicles. This will inform ZeroAvia’s development of a large-scale liquid hydrogen (LH2) refueling truck, an important step as the company progresses its powertrains from gaseous to (LH2) to support larger aircraft.

Related Content

-

Collins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.