BCA Industries introduces “The Beast” shredder unit

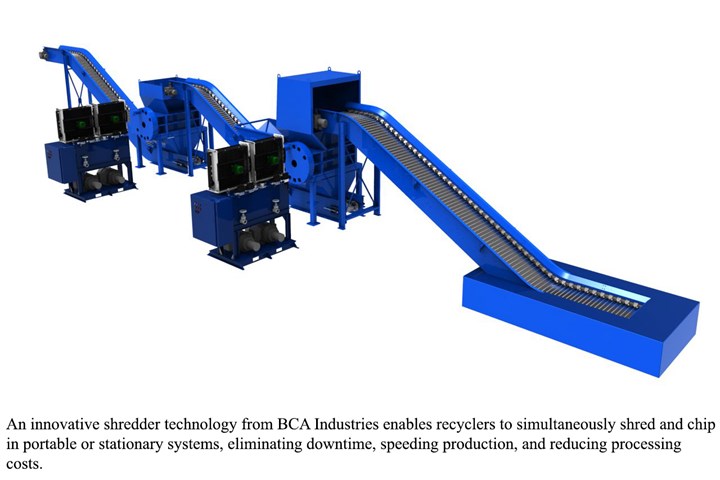

Next-gen shredder for composites recyclers is designed to eliminate catastrophic breakdowns and production downtime by upgrading points of vulnerability and enabling simultaneous shredding and chipping.

All photo credit: BCA Industries.

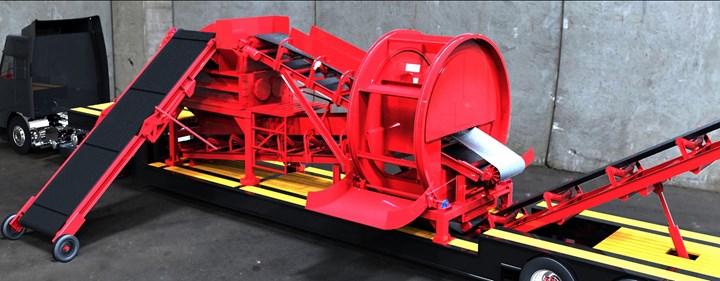

BCA Industries’ (Milwaukee, Wis., U.S.) customizable ES2000 shredder unit called “The Beast,” is ready to help composites recyclers reliably shred even the most challenging composite material scrap — including wind turbine blades — to chips at high volumes using advanced hydraulic systems, cost-effectively improving their production with minimal downtime. The stationary and portable units are also applicable to ferrous/nonferrous metals, electronic waste, truck tires etc.

With 24” diameter hard-faced knives using a base AR-500 alloy, 55-72” x 44” cutting chambers and 8” 4130 Chromoly steel shafts, the unit can quickly reduce any composites scrap. At a total gross weight (not including power supply) of 24,000-38,000 pounds, “The Beast” is designed to shred 15-35 tons of composites or dense materials an hour with 179,000 foot-pounds of torque per knife. When even more throughput is required, BCA Industries says it can be rated up to 800 hp, and use dual cutting chambers. To maximize high-torque throughput and efficiency, it incorporates a pressure compensated variable displacement pump that allows the rpm to increase and decrease based on load.

According to the company, a shredder using this design can produce more than 85% correctly sized material in one pass with less than 10% oversized material.

The unit’s design reportedly addresses the vulnerabilities of conventional shredders by using an inexpensive cluster drive system of eight small hydraulic motors, which create redundancy in the power supply that eliminates much of the possible downtime. These cluster drive motors are off-the-shelf, and readily accessible and they are said to minimize cost while increasing reliability. Use of the cluster drives ensures continuous operability (at slightly lower output), even if one or more need to be replaced.

Further, instead of 7” shafts, 8” Chromoly shafts increase usable life. In place of old HEX shaft design or a double key round shaft, the unit uses a six-key design where the knife literally rides on disposable keys, not directly on the shaft. With the keys taking any abuse instead of the shaft, the design is said to eliminate shaft washout and simplifies knife changes.

Because the unit is designed with a double labyrinth-style drop zone and outboard bearings, this also eliminates any direct path to the shaft bearings. BCA Industries says. It also enables compressed material a path to exit the shredder, eliminating the “catastrophic costs” of bearing and shaft replacement.

To further enhance production, innovative shredders get to the root of the processing bottleneck. Instead of using many shredders to progressively reduce the size of composites scrap, new shredder “knife” technology like BCA’s patented Triplus system (when used in the shredder) can uniformly cut to any size in a single pass without a screen, rapidly reducing scrap to a reclaimable proportion. It uses a bed knife design in a dual shaft shredder to cut the width of the material of the shredder. The size of the end product is based on the size and geometry of the rotary and fixed knives as well as their gap distances.

According to the company, a shredder using this design can produce more than 85% correctly sized material in one pass with less than 10% oversized material. It’s noted that the knife system is also able reduce scrap to the appropriate size with much less energy than typical shearing and grinding equipment. Power efficiency approaches 150% over any standard shredder.

The Beast ES2000.

Further, when the knife technology is used with composites, as well as ferrous/nonferrous metals, electronic waste, tires, ragger tail, C and D waste, MSW, paper and plastics, it is said to dramatically reduce shipping costs by minimizing voids in containers due to oversized material.

Finally, with a programmed “nip cutting” function, labor is saved during the processing of materials when shredding the entire amount in one stream is not possible. Nip cutting (rotating shafts to cut big hunks into small pieces) saves the operator time trying to disassemble, reduce size or cut the material to size.

While such shredding units are typically hydraulic, all-electric versions are an attractive option if a large chamber size is required, but not high torque. All-electric versions do not contain valves and cannot leak hydraulic fluid, making them more simple, quieter, less costly and low-maintenance alternatives.

Related Content

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Johns Manville launches thermal recycling unit for glass fiber waste

The unit provides a projected recycling capacity of more than three tons per hour and will keep more than ten thousand tons of waste out of landfills annually.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)