CMS debuts hybrid LFAM/milling machine

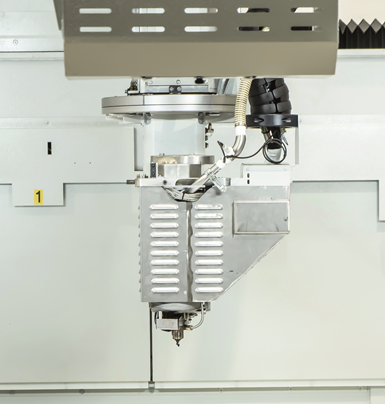

The machining specialist has developed the first iteration of Kreator, a large-format, thermoplastic composite 3D printer and five-axis milling machine for tooling and jigs.

Photo Credit, all images, CMS SpA

In June 2021, multi-axis machining specialist CMS SpA (Zogno, Italy and Caledonia, Mich., U.S.) officially launched Kreator, a hybrid composite 3D printer and multi-axis milling machine. The company plans to debut the machine at in-person trade events this fall.

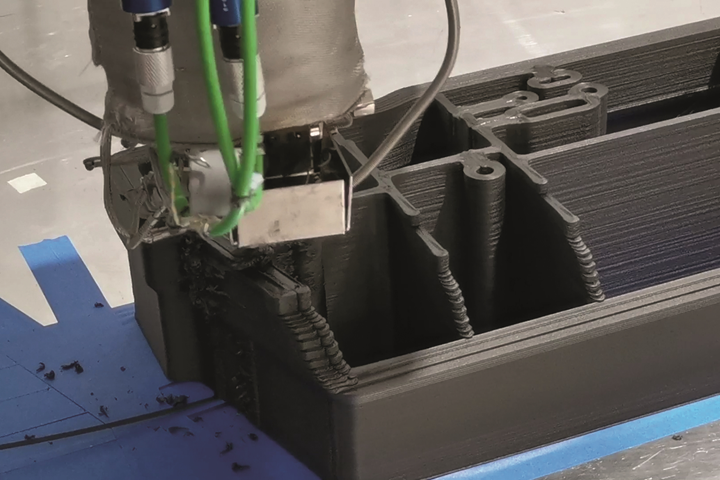

Kreator, which was developed alongside Fraunhofer IWU and will be part of CMS’ Ares machining center product line, combines large-format additive manufacturing (LFAM) with milling, with the goal of being able to print composite components such as tooling and jigs and then finish the parts with the attached five-axis milling machine.

The pilot version of the printer is compatible with 40% carbon fiber-filled PA6, with additional fiber lengths and thermoplastic materials such as PESU, ABS and PEI currently being qualified. Kreator is a single-screw extrusion printer with a build volume of 1800 x 800 x 2000 mm. Parts are cured at room temperature and then the printhead is swapped for a milling machine for finishing.

Maurizio Bernini, product manager of additive manufacturing and new technologies at CMS, explains that the Kreator system is designed to quickly build composite jigs, fixtures and tools that are lighter weight than aluminum counterparts. For example, he says a carbon fiber/PA6 jig can be built in just over three hours using the Kreator machine, and weigh 14.6 kg, whereas the original aluminum version took eight days to build and weighed 114 kg.

“The key,” he adds, “is to control shrinkage and warpage, and to maintain good adhesion between layers by controlling the cooling of each layer.”

The system also is said to save up to five times the material costs, compared to traditional subtractive methods, due to its printing hollow, rather than solid parts.

One application area where CMS sees Kreator being particularly suitable is the manufacture of carbon fiber-reinforced polymer (CFRP) tooling for autoclave-cured parts. Typically, to build CFRP tooling, a master tool needs to be built first, upon which the subsequent tools are molded. With Kreator, a core tool part is printed directly and then covered with a CFRP laminate, eliminating the need for a separate master tool.

According to CMS, to date three machines have been built, and one has been delivered to a customer. With Fraunhofer, CMS is working to develop additional capabilities for next-generation models, such as a larger printhead geared toward marine applications, and a machine that includes two heads for simultaneous printing and milling.

Related Content

-

Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

-

Rocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

-

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

.jpg;width=70;height=70;mode=crop)