Cygnet Texkimp introduces zero-degree filament winding solution

Zero-degree winding, aided by the company’s 3D Winder and Multi-Axis Winder machines, helps manufacturers achieve longitudinal strength in lightweight, structural composite parts.

Share

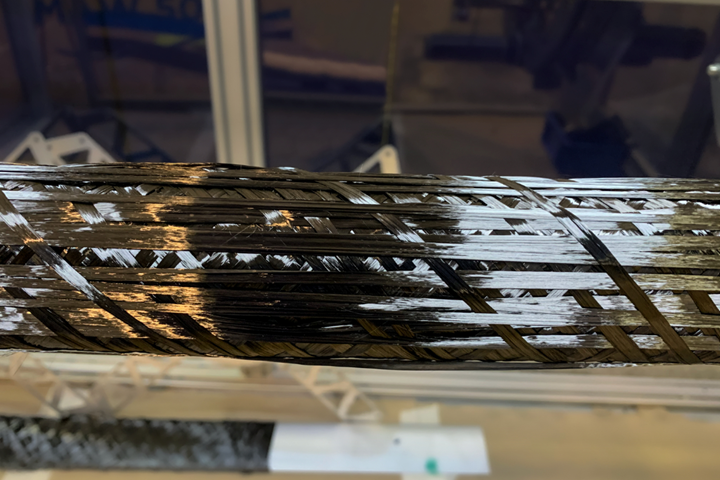

Fiber handling and converting technology company Cygnet Texkimp (Northwich, U.K.) has developed a way of winding composite fibers at a zero-degree angle to create curved and straight structural parts with enhanced mechanical strength using the minimum amount of fiber.

Zero-degree winding — also called axial, unidirectional or longitudinal winding — is reported to be a sought-after technique, particularly among manufacturers of lightweight structural components for the automotive, aerospace and construction industries. The technique exploits the inherent mechanical strength created when fibers are wound straight along the axial load path or the longitudinal axis.

According to Cygnet Texkimp’s Dr. Yan Liu, there are ways of getting close to zero degrees using conventional filament winding, but there is no retaining mechanism to hold the zero-degree fibers in place. Similar properties can be produced by manually pre-wrapping the mandrel, but this is said to be a labor-intensive approach which is unsuitable for high-volume applications.

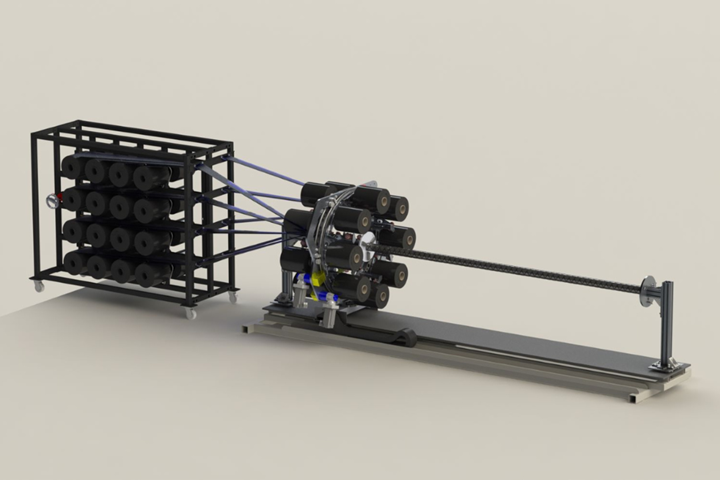

Zero-degree winding describes the action of laying down the fiber in parallel with the direction of the mandrel axis. Cygnet Texkimp says it has developed the process using its 3D Winder and Multi-Axis Winder machines. Crucially, the capability of these two technologies enables manufacturers to create not only straight parts with zero-degree winding but also curved parts, such as fuel pipes for planes, according to the company.

Using the MAW and the 3D Winder makes zero-degree winding possible because the axial fibers are held in place by the winding mechanism. Fibers are fed into the process from a series of (two or three) rotating rings mounted with bobbins of fiber, which move back and forth around a static mandrel, winding as they go. Additionally, a fiber unwinding creel can be incorporated at the start of the process to increase the volume of fiber that can be fed in and laid down in one go, improving throughput efficiency. Adding strength and impact resistance through zero-degree winding instead of by adding larger volumes of fiber means manufactures can make strong parts with minimal fiber and therefore weight, according to the company.

Dr. Yan Liu says the solution is ideal for parts that are subject to a bending load, such as structural side and front impact protection beams for automotive. The level and uniformity of strength that comes from winding directly parallel with the longitudinal path are characteristics that are desirable in high-performance part manufacture.

Related Content

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.