Hexcel introduces G-Vent technology for thick, OOA marine structures

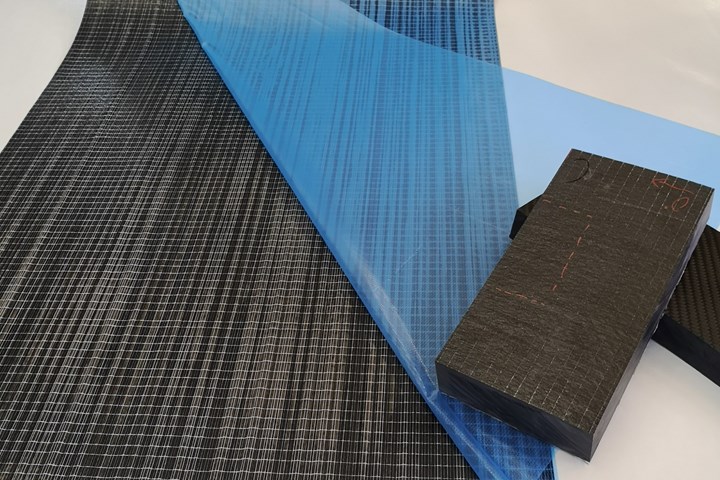

Hexcel marine prepregs are available with G-Vent integrated, enabling out-of-autoclave processing with reduced time, cost and autoclave-comparable porosity for highly loaded masts and foils without debulking.

Photo Credit, all images: Hexcel Corp.

Hexcel Corp. (Stamford, Conn., U.S.) has leveraged its experience in aerospace and wind energy to develop a novel technology for out-of-autoclave (OOA) processing. It is reported to deliver significant reduction in process time and cost for marine manufacturers without compromising mechanical performance.

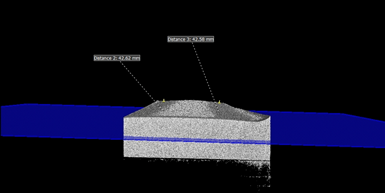

Hexcel’s G-Vent technology targets OOA processing of highly loaded, thick section marine structures such as masts, foils and wind-assisted ship propulsion (WASP) components. Hexcel’s full range of marine prepregs are now available with integrated G-Vent technology, reducing the requirement for debulking steps and ensuring very low porosity (<1%) irrespective of the laminate thickness, according to the company.

To evaluate G-Vent, Hexcel completed a test program with Q.I. Composites Srl (Piverone, Italy), a company that performs non-destructive testing (NDT) in performance marine applications. The program evaluated HexPly 40-layer prepreg samples prepared with G-Vent technology. Carbon fiber panels made with no debulking revealed approximately three times less porosity than those using a typical 10-minute debulk with every second ply. Ultrasonic and computed tomography (CT) scan analysis by Q.I. Composites confirmed the void content results with porosity levels in line with state-of-the-art autoclaved carbon prepreg foils. Hexcel also notes that key tensile, compressive and interlaminar shear strength results were also higher for the G-Vent panels.

Related Content

-

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

-

CompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

-

GKN Aerospace, Joby Aviation sign aerostructures agreement

GKN Aerospace will manufacture thermoplastic composite flight control surfaces for Joby’s all-electric, four-passenger, composites-intensive ride-sharing aircraft.