Hexcel presents HexPly prepregs geared toward marine

New intermediate and high modulus HexPly M79 composite materials are optimized for best-in-class performance.

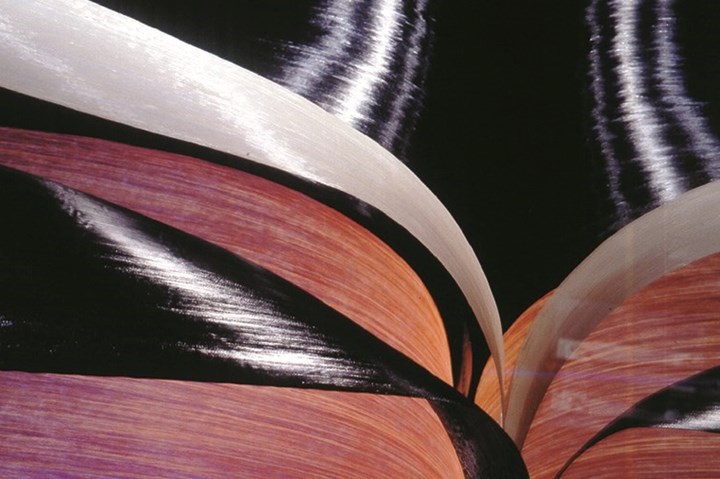

Photo Credit: Hexcel

Hexcel (Stamford, Conn., U.S.) highlights its latest developments for the marine market, new intermediate and high modulus fiber HexPly M79 prepregs.

The intermediate modulus prepreg combines the low temperature curing and simple processing of the DNV GL-accredited HexPly M79 resin system with the stiffness of HexTow IM2C fiber, creating an optimized composite material for highly loaded components. Originally developed to provide best-in-class performance for America’s Cup and IMOCA hull and deck structures, the new combination is reported to minimize structural deformation under load in parts such as rigs, foils and other appendages.

For a high modulus solution, HexTow HM54 fiber is also now available with the HexPly M79 resin system. Hexcel says that the mechanical properties of HexTow HM54 fiber enable structural designers to achieve higher safety margins for stiffness- and strength-critical applications. Both products can be manufactured with Hexcel G-Vent technology for out-of-autoclave processing, delivering a reduction in process time and cost without compromising mechanical performance.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.