Kordsa targets phenolic-based sandwich panel toward aircraft interiors

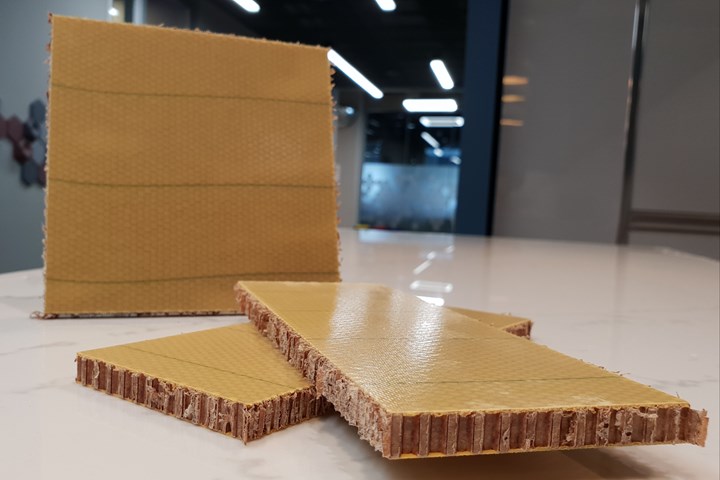

The sandwich panels comprise glass fiber/phenolic skins surrounding a Nomex honeycomb core.

Source | Kordsa

Tire, construction reinforcement and composites technologies company Kordsa (Izmut, Turkey) has introduced a new line of honeycomb composite sandwich panels for the cabin interior of commercial airplanes. The company’s Composites Center of Excellence (CTCE), founded in 2016, played a significant role in the development of the technology. The material, comprised of glass fiber in a phenolic matrix surrounding a honeycomb core, is targeted toward aircraft galley applications. Kordsa selected phenolic for its flame-retardancy. The honeycomb core, provided by Advanced Honeycomb Technologies (San Marco, Calif., U.S.), a subsidary of Kordsa, is also phenolic-based. Each honeycomb cell is hexagonal-shaped and measures 3.2 millimeters wide. Kordsa says its composite sandwich panels can withstand greater bending loads than the leading brand and is able to withstand peel loads in either direction.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.