Markforged optimizes 3D-printed part performance with Performance Advisor

The physics-based analysis method is use case independent, automatically providing print settings that will give users options to increase part strength while optimizing for cost and print time.

Markforged (Waltham, Mass., U.S.) has developed a patent-pending, physics-based analysis method of analyzing part performance — called Performance Advisor — that recommends print settings that will make users’ parts a known quantity stronger, all without having to specify a use case, keeping added costs and print time to a minimum and being fully automated.

3D-printed parts that considered advantageous for their strength and durability. The first step to manufacturing strong parts with Markforged printers is to configure print settings in Eiger. Several of these can influence the strength (performance) of a part, some more than others. For example, it is clear that adding continuous fiber reinforcement will make a part significantly stronger, but it is less clear what the impact will be when adding an extra wall layer, or adjusting the fill density. Further, strong parts are desired but not at the expense of excessive increases in material cost and print time.

According to Markforged, customers are able to use its Simulation tool to explore how changes in print settings impact part performance, and optimize for cost and print time. However, Simulation requires a known use case — how the part will be loaded and how it interacts with other objects when it is in service — which is often unknown.

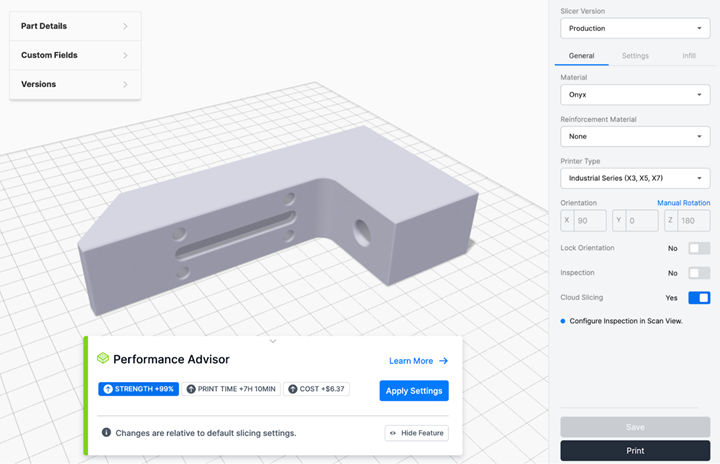

Alternatively, with Performance Advisor, once a part is saved in Eiger, the tool will automatically analyze the part and recommend print settings that, relative to the default settings, improve the strength. Recommended settings can be applied with one click, or ignored should they not meet expectations.

Markforged provides an example with the characteristic shape of the lowest energy eigenmode for an L-shaped bracket. This is one of the shapes in which this part would naturally vibrate. This shape provides Performance Advisor with information about the regions of the part that are most susceptible to deformation and stress and enable it to find print settings that make those regions stronger.

Computing the lowest energy eigenmode is the first step. The second step is to run a machine learning driven optimization procedure that scores print settings using three variables: strength, material cost and print time. Print settings that score high in strength and low in cost and print time are considered optimal. Such configurations are what Performance Advisor aims to recommend.

The capabilities of Performance Advisor are said to grow over time. For the initial release, important limitations are:

- Onyx is the only supported material.

- The fill pattern is triangular and the default fill density is held constant.

- Performance Advisor may not be able to analyze parts with extremely complex STL meshes.

-

Wall layers and roof and floor layers are the only print settings adjusted.

When comparing Simulation and Performance Advisor, Markforged notes a few key differences. First, as mentioned above, Simulation requires a use case, which means the results generated are based on how the part will be used in the real world, whereas Performance Advisor is use case independent. In addition, Simulation computes a Safety Factor, which tells users the load when a part will begin to fail. Alternatively, Performance Advisor provides the strength increase of the recommended part relative to the part with default settings. This does not tell you anything about the load the part can withstand. Finally, Simulation is powered by a finite element analysis (FEA) engine, tailored for the fused filament fabrication manufacturing method. Performance Advisor uses a patent-pending analysis methodology, based on the lowest energy eigenmode of the part.

Simulation is available in the Advanced Digital Forge Subscription plan. Performance Advisor is available at no cost to all users that have a printer registered to their Eiger organization.

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreRead Next

Markforged introduces Digital Source platform for manufacturer-certified parts

Digital Source aims to solve supply chain challenges with licensed, digital inventory printed through Markforged’s global 3D printer network at the point of need.

Read MoreUpgraded industrial 3D printers support continuous fiber capabilities

JEC World 2024: Endless Industries offers 3D printing customers integration of its proprietary printhead, software and fiber filaments to achieve the benefits of lightweight composite parts.

Read MoreMarkforged develops composite 3D printing technology

The FX10, a composite 3D print system with built-in automation, and Vega, a carbon fiber-filled PEKK material from Markforged, expand on 3D printing applications for customers.

Read More

.jpg;maxWidth=300;quality=90)