Markforged develops composite 3D printing technology

The FX10, a composite 3D print system with built-in automation, and Vega, a carbon fiber-filled PEKK material from Markforged, expand on 3D printing applications for customers.

The FX10 features built-in automation for quality assurance and print routines designed to deliver strong, accurate parts every print. Photo credit, all images: Markforged

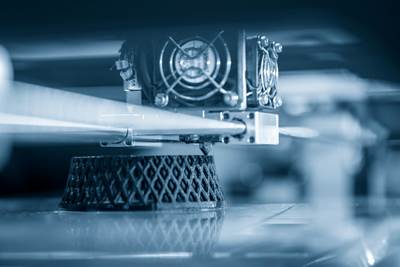

Markforged (Waltham, Mass., U.S.) aims to strengthen manufacturing resiliency by enabling industrial production at the point of need. In this spirit, the company has developed FX10, an industrial composite 3D printer designed for use on the factory floor, and Vega, a carbon fiber-filled polyetherketoneketone (PEKK) that can help with weight, cost and lead time.

FX10

The FX10 is designed to improve manufacturing line productivity and profitability. It empowers users to print the right part when and where it is needed, reducing costs and cutting lead times from months to days when compared to traditional manufacturing methods.

“The FX10 allows manufacturers to slash original part replacement costs when compared to traditional methods and keep production lines running without worrying about supply chain issues or spare parts inventory,” says Shai Terem, CEO of Markforged. “The FX10 can accelerate the digitization of the manufacturing floor by increasing the adoption of digital inventory to build supply chain resiliency. Our customers now have the potential to save even more capital by reducing physical inventory and boosting production yields while decreasing operating costs.”

The printer’s modular systems are engineered to be expanded and upgraded with additional capabilities. For example, the FX10 has been designed to incorporate a printhead-integrated vision module to capture detailed part images and data to promote part quality and improve printer performance. The continuous fiber reinforcement (CFR) print system delivers high print quality in a heated print chamber, providing print speeds that are nearly twice as fast and print sizes that are up to twice as large as previous Markforged industrial series printers. As a result, the FX10 enables the replacement of metal parts with advanced composites.

The FX10 was designed to enable easy adoption on the manufacturing floor starting with the first line operator. A simple touchscreen interface combined with automation and quality assurance technologies enable users to get more parts out of the FX10 with fewer interactions needed by the operator before and during a print.

The printhead-mounted optical sensors automatically verify the dimensional accuracy of parts during the print to confirm consistency and reliability, while also assessing machine health and performance. The laser micrometer in the FX10 scans parts during printing and assists with the machine’s automatic calibration. Inspection software interprets the data from the sensors for dimensional verification, providing users with quality assurance as soon as a print finishes.

The material drawer of the FX10 contains built-in, individually sealed storage bays for up to four 800cc spools. FX10 is able to automatically execute spool changeovers between filament storage bays during a print, and users can reload empty spool bays without disrupting a print.

The Digital Forge is the additive manufacturing (AM) platform for modern manufacturers that enables every aspect of the FX10. A complete AM platform consisting of printers, cloud-enabled software with process improvement tools and a wide range of industrial materials, the Digital Forge is purpose-built to integrate into existing manufacturing ecosystems. With the Digital Forge, users can share parts across their organization, and monitor fleet performance from a central location.

Vega is a carbon fiber-filled PEKK that can save weight, cost and lead time by replacing aluminum.

Vega

Vega is an ultra-high performance filament designed for aerospace manufacturing on Markforged’s FX20 printer. Vega offers exceptional strength and is expected to bring customers advantages in weight reduction, cost efficiency and lead time savings.

Vega builds upon Markforged’s experience of engineering chopped carbon fiber-filled polymers that deliver strength, precision and surface quality. Markforged developed Vega to be compatible with the FX20’s CFR technology to deliver aluminum-strength parts.

“Vega is formulated to expand aerospace applications for our customers,” Terem says. “Vega incorporates PEKK, a proven material in aerospace that possesses excellent strength and stiffness. We believe this material will set the standard in print quality for high-temperature thermoplastics and expand the adoption of our FX20 printer.”

Vega is said to exhibit optimized surface quality that exceeds most high-temperature plastics used in AM. With a smooth black matte surface finish, Vega offers an as-printed finish for aesthetic aerospace parts. The material resists warping, a problem for high-temperature plastics, and exhibits flame, smoke and toxicity (FST) resistance for high-value applications.

Vega’s print quality advantages are expected to drive favorable business outcomes for customers, particularly with production parts. Fewer defects and minimal warpage mean less post-processing to achieve production surface quality, enabling for higher part acceptance rates during inspection.

Combined with Markforged’s CFR technology, Vega provides increased design flexibility, without sacrificing strength, which opens applications unreachable with other high-performance filaments. The material expands the utility of 3D printing with CFR for aerospace manufacturing from aesthetic parts to non-critical structural parts in interiors and similar applications.

Related Content

Hitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreFormula 1 team adopts Roboze 3D printed composites

The Visa Cash App RB Formula 1 team is collaborating with Roboze to reduce weight and create parts with complex geometries via carbon fiber/PEEK.

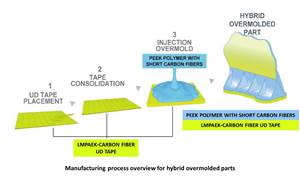

Read MoreTool Gauge, Victrex partner to develop co-molded composite aircraft parts

Novel hybrid overmolding technology achieves novel thermoplastic composite parts to replace machined aluminum components on commercial aircraft, as well as reduce manufacturing costs and timeline.

Read MoreRead Next

Markforged introduces Digital Source platform for manufacturer-certified parts

Digital Source aims to solve supply chain challenges with licensed, digital inventory printed through Markforged’s global 3D printer network at the point of need.

Read MoreXenia Materials reveals composite materials for FDM printing

A new range of 3D printing materials are formulated for use on any pellet-based fused deposition modeling printer.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More