Markforged introduces Digital Source platform for manufacturer-certified parts

Digital Source aims to solve supply chain challenges with licensed, digital inventory printed through Markforged’s global 3D printer network at the point of need.

Markforged Holding Corp. (Waltham, Mass., U.S.) announces Digital Source, an on-demand parts platform built to enable the licensing and 3D printing of manufacturer-certified parts when and where they are needed, without the cost or hassle of physical inventory management.

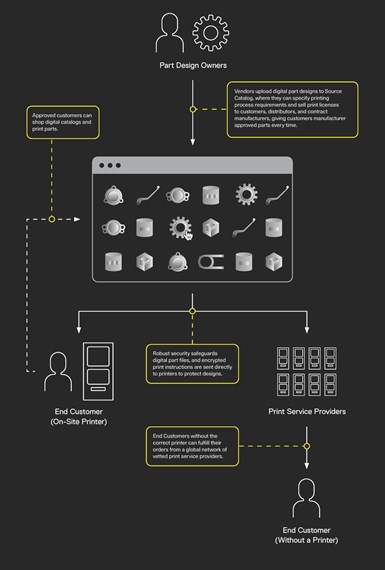

Digital Source enables vendors to upload digital part designs which can be securely licensed to customers, distributors and contract manufacturers. Once uploaded, Digital Source end users will have the ability to license the right to print parts on-site or through a growing network of approved print service providers.

Parts can be made out of Markforged’s entire materials offering — this includes parts made out of Onyx, a nylon-based composite material with chopped carbon fibers, which can also be reinforced with continuous carbon, Kevlar and glass fibers. Parts can also be printed in multiple metals including copper, stainless steel, tool steels and Inconel.

“Digital Source gives us the agility to print spare parts where they are needed, so we can get machinery back up and running much faster and minimize our downtime,” explains Jeremy Haight, principal engineer at Vestas Wind Systems A/S (Aarhus, Denmark). “Time equals a very high dollar value for us — a line down in one of our factories is a big deal, but a turbine that has gone down can cost even more. If we can access and print the part we need, we can get that line or turbine back up and operational much quicker.”

Digital Source not only can simplify logistics, “but can also build resiliency into the supply chain and increase profitability as a result of these efficiencies,” Shai Terem, CEO of Markforged, adds. “With Digital Source, parts can be digitized and printed at the time and point of need without the need to be manufactured in advance, shipped and stored until needed.”

Digital Source is designed to offer consistent, reliable, turnkey production for 3D-printed parts. Markforged is delivering the promise of digital warehousing by integrating 3D printing software, materials and hardware with end-to-end process control. Vendors can specify and lock printing process requirements so that customers get manufacturer-certified parts on-demand. Robust security safeguards digital part files, and encrypted print instructions are sent directly to printers to protect designs, allowing customers to just “Press Print.”

Related Content

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.