Mechnano, Bomar introduces E35B+ masterbatch with increased CNT concentration

Using Mechnano’s D’Func process, the new masterbatch of ogolimers enables 3D printing resin development with improved mechanical and nano-uniform electrical performance.

Photo Credit: Mechnano

Mechnano (Mesa, Ariz., U.S.), in partnership with Bomar (Torrington, Conn., U.S.), has developed a E35B+ masterbatch in Bomar’s BR-952 oligomer, specifically designed for formulators in the additive manufacturing (AM) industry. The masterbatch uses Mechnano’s technology, D’Func (discrete, dispersed and functionalized carbon nanotubes), that enables AM resin development with improved mechanical and nano-uniform electrical performance.

“Mechnano’s product development team is committed to improving our technologies and AM solutions,” says Mechnano director of applications and technology Dr. Olga Ivanova. “This dedication has led to the development of a new masterbatch that delivers excellent results while requiring a smaller quantity in the final resin formula, making it more cost-effective.”

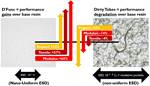

E35B+ offers 2.5 times higher carbon nanotube (CNT) concentration compared to Mechnano’s original E35A ESD masterbatch, according to the company. It is particularly suitable for the development of SLA, DLP or jettable 3D printing resins that require rigidity and high tensile strength. With adjustable resistivity ranging from 106-1010 Ω, E35B+ promotes absence of carbon trails and can be incorporated into a formula without the need for high shear mixing.

“This new, more highly concentrated dispersion by Mechnano should improve the versatility of this product and further enable ESD resins for a wide range of applications,” says David Robitaille, global brand director for Bomar.

E35B+ offered by Mechnano makes use of its distinctive D’Func process. The process is designed to address the issue of clumped and roped CNTs in materials, ultimately improving mechanical and electrical performance. By minimizing these clumps and functionalizing CNTs, Mechnano checks that its masterbatches provide stable CNT dispersions. This is crucial, as dispersions of clumped CNTs are known to negatively impact mechanical properties of materials, leading to inferior part performance. E35B+ can be obtained directly from Mechnano or Bomar.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

.jpg;maxWidth=300;quality=90)