Notus Composites launches low-temperature curing epoxy prepreg

NE7 formulation enables composite manufacturers to cure components at temperatures as low as 70˚C, reducing energy consumption and enabling more cost-effective tooling options.

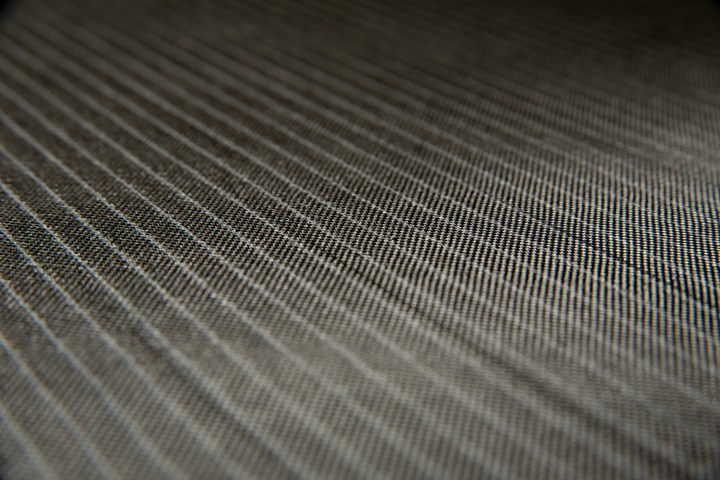

Notus NE7 low-temperature curing prepreg. Photo Credit: Notus Composites

Notus Composites (Ras Al Khaimah, United Arab Emirates), a producer of epoxy prepreg materials, has launched its new NE7 low-temperature curing prepreg system. The new Notus NE7 formulation reportedly enables composite manufacturers to cure components at temperatures as low as 70˚C, reducing energy consumption and enabling more cost-effective tooling options.

Notus Composites has developed the new NE7 prepreg systems for applications across the marine, architecture, industrial and wind energy sectors. Existing prepreg manufacturers can now use more cost-effective composite tooling, with new prepreg users able to switch easily from existing infusion or wet laminating processes without creating new, expensive high-temperature tooling.

A deck for a racing yacht, which uses NE7 woven and multiaxial carbon fibre prepregs. Photo Credit: Notus Composites

According to Notus Composites, NE7 prepregs can be cured at temperatures as low as 70˚C, with the standard cure cycle being 12 hours at 70˚C, matching the typical cycle time for an infused part with a component Tg of 85˚C. NE7 materials reportedly have a good outlife of 30 days at 20˚C and are available in all prepreg and Notus single-sided N1-Preg formats with unidirectional (UD), multiaxial and woven reinforcements. NE7 can also be supplied as a resin film.

Notus Composites’ EPFR-609 FR prepreg materials (tested and certified to NFPA 285, ASTM E84 and EN13501-1) are now available with the NE7 low-temperature curing technology, combining additional processing options with leading fire performance.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.