Rapid Robotics launches ready-to-work robotic machine operator

“Out of the box,” the Rapid Machine Operator — which automates common machine tasks for a variety of industries — can be up and running in hours, no systems integration required.

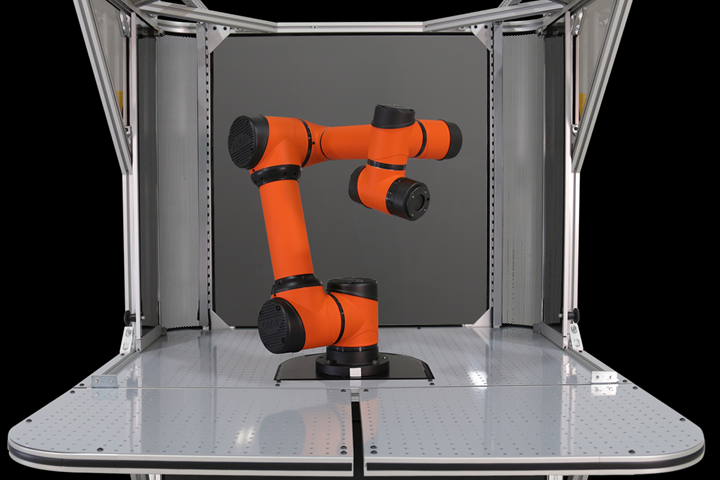

Photo Credit: Rapid Robotics

On Nov. 18 Rapid Robotics (San Francisco, Calif., U.S.) launched its first ready-to-work robotic machine operator, which is said to give contract manufacturers an easy, affordable way to automate common machine tasks and compete with offshore facilities.

According to the company, the Rapid Machine Operator is an industrial cobot that needs no programming or systems integration. ‘Out of the box,’ it can perform simple tasks such as injection molding, pad printing, heat stamping, pick and place and can execute dozens of other tasks across manufacturing sectors including medical devices, electronics, CPG (consumer packaged goods), automotive, etc.

At $25,000 per year, the company contends that its Rapid Machine Operators cost 75% less than human operators and 90% less than other robotic solutions. Return on investment (ROI) is also said to be delivered within 3-4 months from the time of subscription, increasing operating profits an average of $110,000 per year for each unit installed.

Rapid Robotics adds that easy management is a large advantage to its industrial cobots, even for non-technical users. Users simply select a machine type from Rapid’s touchscreen interface, input variables specific to the project and the cobot completes the rest. Users can oversee numerous Rapid Machine Operators at once and quickly configure them for new jobs as needed, making it ideal in high-mix environments.

The Rapid Machine Operator comes with fixtures, grippers, cameras and all other components. Its proprietary built-in computer vision system quickly finds parts and automatically creates optimized motion paths for faster cycle times — all without a single line of code or additional costs. Rapid takes care of the initial same-day setup and provides support at no additional charge.

Further, the cobot receives new capabilities monthly over the air and shares intelligence in real-time through the cloud, so the entire fleet becomes more valuable the longer it’s on the job.

Related Content

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

Broetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

-

Babyark launches smart, composites-intensive car seat

Impact-absorbing car seat approaches safety holistically with carbon fiber and D3O materials and embedded sensors for real-time monitoring.

.jpg;maxWidth=300;quality=90)