TemperChip machining temperature sensor for composites

Patented device provides real-time machining data to monitor and accurately predict tool life, opening up the horizons to measure a variety of parameters between cutting tool and material.

Share

Read Next

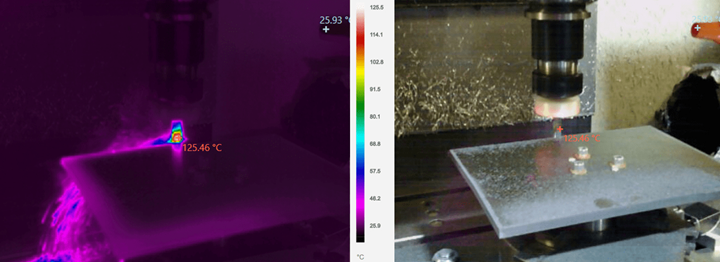

The TemperChip noncontact temperature machining sensor. Photo Credit, all images: TemperChip

When utilizing a cutting tool, users can only roughly estimate the tool life. Tool vendors can supply tool life data, but this data is often generalized and inaccurate because of the variety of applications for cutting tools. TemperChip is a noncontact temperature machining data measurement device installed on cutting tools or machine holders. The device is patented by Yaakov Manas and Eli Yudkevich as a solution for the machining of composite materials while implementing continuous control of the developing temperature measurement. TemperChip opens the potential to track several different work parameters between the machine and the work material, providing a way to monitor tool life and efficiency.

Estimating tool life can lead to potential problems. Determining when to replace the tool is often up to the operator’s initiative, leaving room for human error in either replacing the tool too early or too late. TemperChip features interactive communication functions that alert operators by use of red LED lights, smartphone application and/or machine control.

Components inside the TemperChip include various sensors, a miniature battery, an electronic control board, a BLE communication chip and a recharge chip. The measurement device also has the option to be calibrated according to critical points (10-15% under the limits) that are expected to cause damage. Calibration will be done according to the work specimen and/or workpiece material type.

For example, the glass transition temperature (Tg) of carbon fiber-reinforced polymer (CFRP) causes losses in mechanical properties of the material and delamination occurs at 130°C. Under these conditions, the device will be calibrated to around 110-115°C.

Based on the data received from the device, operators can adjust the machine’s working parameters and stop and replace the tool as needed. The parameters available for measurement include process temperature, load and torque, vibrations and cutter wear.

When the machining process meets the threshold points as indicated, an LED light on the device warns the operator. The operator can manually stop the machine or replace a tool. Second, the machine can optionally receive communication transmission from the device and start with prevention tactics, such as tool replacement with the magazine, feed rate reduction, spindle speed reduction and a chip load reduction. In accordance with Industry 4.0 methodology, the machine controller will be programed with algorithm to apply the most efficient prevention step in accordance with the scenario on hand.

By providing the ability to accurately predict tool life, TemperChip gives users a reduction in production costs and cutting tools, enables high efficiency tool use and removes the need for a tool life validation process.

Related Content

-

Technology Marketing Inc. to distribute VacPuc digital sensors

VacPuc is expanding its range of global distributors to deliver its vacuum pressure measurement solution to the composites market.

-

The evolution, transformation of DEA from lab measurements to industrial optimization

Over the years, dielectric analysis (DEA) has evolved from a lab measurement technique to a technology that improves efficiency and quality in composites production on the shop floor.

-

Streamlining aerospace composites operations with RFID tracking

Tier 1 Sekisui Aerospace’s implementation of RFID tracking, sensors and Xemelgo software at two of its production facilities led to increased productivity, eliminating bottlenecks and reducing labor costs.