Thermal oxidizers support reduced emissions for industrial manufacturing

CAMX 2023: Committed to clean energy, Conifer Systems’ wide range of emissions control systems enable companies to control VOCs, hazardous air pollutants and other greenhouse gases.

Conifer Systems (Houston, Texas, U.S.) designs, manufactures and installs state-of-the-art emissions control systems and provides aftermarket services to enable industries to meet and exceed their environmental goals. Conifer provides innovative emissions control systems that enable companies to meet federal, state and municipal regulatory emissions standards, maximize uptime and minimize cost. Through reliable environmental solutions, Conifer is committed to clean energy and creating industrial efficiencies.

Regenerative thermal oxidizers (RTO) destroy high volumes of emissions through very high heat using ceramic media. RTOs are commonly configured in two, three and multi-canister systems. RTOs are well suited for any process that requires continuous operation such as paint booths, ethanol production, pharmaceuticals, chemicals, odor destruction and mining fugitive emissions applications.

Direct-fired thermal oxidizers (DTFO) destroy emissions and can maintain continuous destruction rate efficiency (DRE) without interruption for long prolonged periods of time, according to Conifer. DFTOs can be used in a variety of applications including natural gas processing, refineries, tank farms and chemical processing.

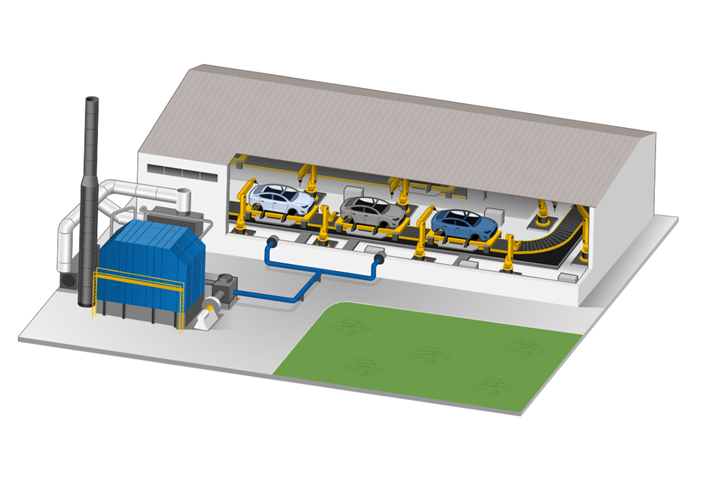

Thermal recuperative oxidizers (TRO) are a direct-fired thermal oxidizer with a primary or secondary heat recovery system to preheat process air instead of using natural gas. TROs are usually used in natural gas processing, chemical processing, agricultural feed, automotive and coal coating.

Catalytic oxidizers (CATOX) destroy emissions using a catalyst. This enables the CATOX’s operating temperature to be lower than a traditional thermal oxidizer, which uses less energy and requires less fuel. CATOX’s are often found in the pharmaceuticals industry for medical sterilization processes, among other applications.

Enclosed flares are used to destroy emissions in areas where an open flame is not permissible and where the gas stream has low levels of oxygen. Enclosed flares are said to be a god option for strict air quality regulations and for facilities that require equipment with a small footprint. Because of this, enclosed flares are often found in natural gas processing, refinery, tank farm, chemical processing and well drilling site applications.

Finally, vapor combustor units (VCU) operate at high temperatures and process a vent stream that is not flammable until it reaches the inside of the VCU combustion chamber. The chamber is lined with high-temperature insulation to protect the outer steel shell. A soft refractory lining is installed to enable rapid heat-up and reduces expansion and contraction. VCUs can often be found in natural gas processing, refineries, tank farms, chemical processes and well-drilling site applications.

Related Content

-

Epoxy curing agents designed for composite applications

CAMX 2023: Dixie Chemical specializes in anhydride-based epoxy curing agents, including NMA.

-

CAMX announces general session presenter, open registration

Attendees registered for the Oct. 31 – Nov. 2, 2023 event in Atlanta, Georgia, are invited to attend this year’s keynote put on by Joan Higginbotham, a former NASA astronaut and president of aerospace consulting firm Joan Higginbotham Ad Astra LLC.

-

Winding software developed for filament winding machines

CAMX 2023: Roth Composite Machinery focuses on automation, safety and time savings.