Search Results

Showing 61 – 70 of 91 resultsJEC World is the composites industry’s largest trade show and did not disappoint this year.

Automation and robotics can go a long way toward increasing capacity and growing a business dedicated to aerospace manufacturing. But Trinity Precision has learned that refining the indirect and unseen aspects of its operations can be just as valuable.

A new video from NASA Dryden shows how aircraft wing morphing technology is being used to develop quieter and more efficient aircraft systems.

IAI’s fully automated “one-shot” RTM production line cuts helicopter seat cost 30% vs. hand layup prepreg.

Capable of volume production, thermoplastic composites will gain new market share in the aerospace industry.

John Russell, who manages nonautoclave research programs for the Air Force Research Laboratory (AFRL, Wright-Patterson AFB, Ohio), recently threw down the gauntlet at the Fall SAMPE conference in Salt Lake City, Utah: “Give us a 25 percent improvement in notch properties with no microcracking in high-modulus fibers.” While OOA prepreg suppliers can’t do much about fiber microcracking, Advanced Composites Group (ACG, Tulsa, Okla.) already has announced that its XMTM47 material will be commercial by next year, designed for 120°C/248°F service with the increased notched performance requested.

Israel Aerospace Industries ramps production while reducing costs and improving quality thanks to integrated optimization software.

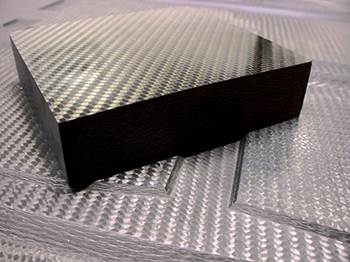

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Israel Aerospace Industries ramps production while reducing costs and improving quality thanks to integrated optimization software.

HPC’s technical editor Sara Black says recessionary scorn of private flight unnecessarily harmed the economically vital general aviation industry.