JEC World 2018: The highlights

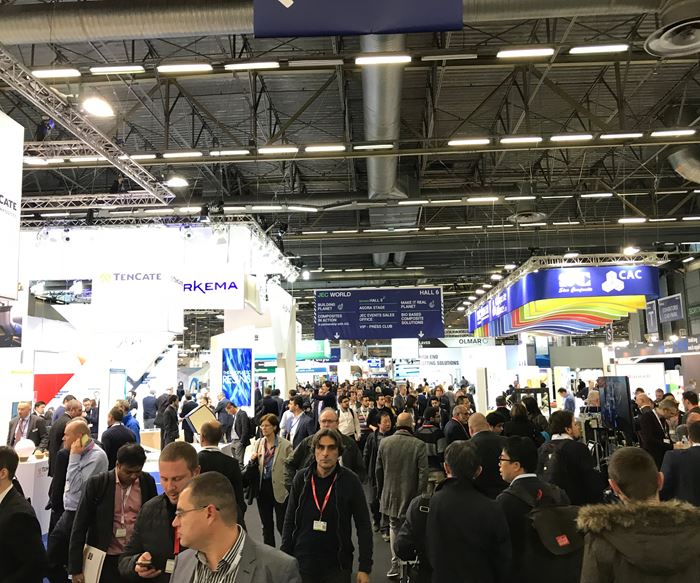

JEC World is the composites industry’s largest trade show and did not disappoint this year.

JEC World is the composites industry’s largest trade show and did not disappoint this year (March 6-8, Paris, France). The show, as usual, featured a variety of new products and technologies, as well as a fertile environment for the exchange of information — much of it fact, some of it rumor, all of it interesting.

Possibly the most intriguing composites industry developments of late occurred immediately before and after the show. Just prior, General Motors announced that its 2019 GMC Sierra Denali pickup truck would offer a carbon fiber/nylon bed made by Continental Structural Plastics (CSP, Auburn Hills, MI, US). More on this below. Just after the show, Toray Industries (Tokyo, Japan) announced that it is acquiring TenCate Advanced Composites (Nijverdal, The Netherlands) in an effort to shore up its thermoplastics capabilities in advance of the next wave of commercial aircraft development. What follows is a sampling of what else CW learned at the show.

ELG Carbon Fibre (Coseley, West Midlands, UK), known for recycled carbon fiber materials, announced plans to increase its Coseley facility capacity to satisfy demand from commercial applications that require significant product supply. The company says the investments will increase the capacity to recover carbon fiber from uncured prepreg and laminate feedstock and to further commercialize the company’s CARBISO product line for reinforced thermoplastic compounds. ELG was in the spotlight as a winner, in the Railway category, of a JEC Innovation award for its participation in a research project to produce a novel rail “bogie” or frame (to which the axles and wheels are attached, to support a locomotive or rail cars) made with recycled carbon materials.

GKN Aerospace’s (Redditch, Worcestershire, UK) Fokker business (Papendrecht, The Netherlands) group revealed that it continues to move forward with innovative thermoplastic composite aircraft parts. The company has been a supplier to Gulfstream Aerospace Corp. (Savannah, GA, US) for more than 20 years, in all of GAC’s large and ultra-large programs. It makes a common thermoplastic rudder part for the G500, G600, G650 and G650ER and produces the entire empennage structure for the G550, G650 and G650ER.

An interesting collaboration was announced at the show between CG TEC (Spalt, Germany) and Refitech (Waalwijk, Netherlands), two providers with a long history of producing client-specific industrial composite solutions in a wide range of application areas, using a wide range of composite materials and processes. The purpose of the new partnership is to cooperate in providing the composites industry, and in particular, small start-ups or entrepreneurs, with off-the-shelf, standard, carbon fiber products — round and square tubes, rods, plates, cables, connectors, braids and more.

Schmidt & Heinzmann (Bruchsal, Germany), known for its sheet molding compound (SMC) machines and expertise, reported installation of what it claims is the most modern machine available for SMC manufacture. The production line can produce different SMC products by accessing various resin systems and combining them with various fiber types; the state-of-the-art manufacturing machine is about to be commissioned within the next month. Also announced was a completely automated preforming process machine for production of composite leaf springs, delivered to a Germany technology research center.

Stratasys Inc. (Eden Prairie, MN, US) gave an overview of its 3D printing initiatives, and a look at its latest machine, the fully-automated Fortus 900 for aircraft interior parts. The company has worked with the National Institute for Aviation Research (NIAR, Wichita, KS, US) on development of material standards and allowables for Ultem 9085 resin material (manufactured by SABIC, Riyadh, Saudi Arabia).

TxV Aero Composites (Bristol, RI, US) is a 2017 joint venture of Tri-Mack Plastics Mfg. Corp. (Bristol, RI, US) and Victrex (Cleveleys, Lancashire, UK and West Conshohocken, PA, US), which combines Tri-Mack’s experience in high-temperature thermoplastic composite parts manufacturing with Victrex’s legacy of thermoplastic polyketone (PAEK) solutions. The intent is to offer a range of PAEK composites, from custom laminates to pre-formed composite inserts for hybrid molding processes, as well as design services, finished composite parts and complete over-molded hybrid composite components and assemblies, to aerospace.

Web Industries (Marlborough, MA, US) announced that it has changed the name of its Advanced Composites division to Aerospace division. The name change follows Web Industries’ 2017 launch of its Thermoplastic Composite Development and Qualification Center in Atlanta and complements the company’s latest aerospace product development, the new SpoolKit logistics solution. The SpoolKit consolidates formatted composites in a single container in the order with which they will be used by aerospace OEM customers. Web also reports that its Aerospace division has earned official accreditation from Nadcap (National Aerospace and Defense Contractors Accreditation Program) covering its aerospace-related composite ply cutting and kitting operations.

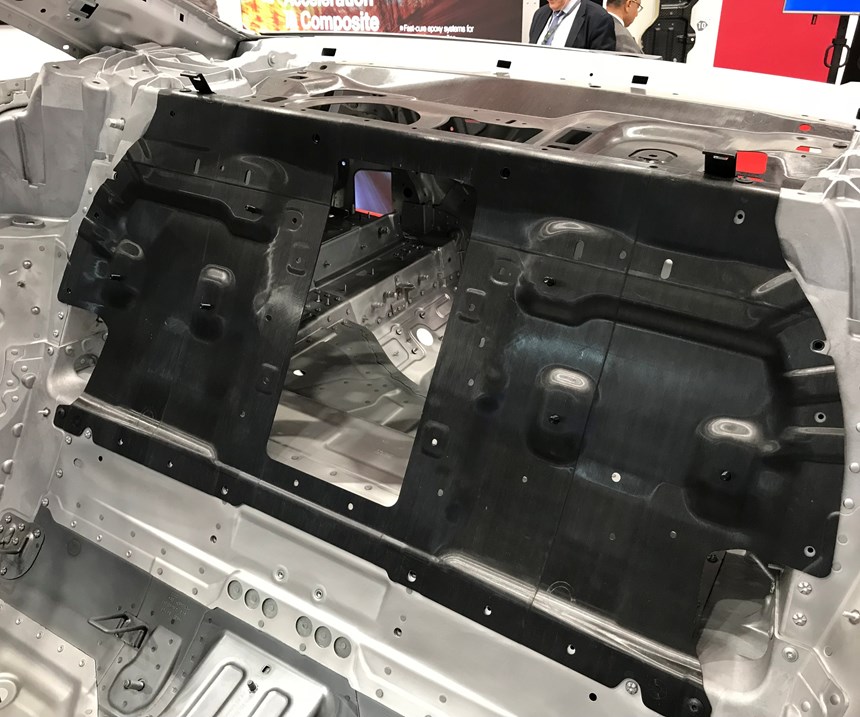

Continental Structural Plastics (CSP) confirmed that is is the manufacturer of the carbon fiber composite pickup bed for the 2019 GMC Sierra Denali. CSP manufactures the beds at its facility in Huntington, IN, US. CSP would not confirm the process used to make the beds, but did confirm that the material is discontinuous carbon fiber and the resin matrix is nylon. It is known, however, that GM and Teijin Ltd. (Tokyo, Japan, which owns CSP) had worked for several years on development of Teijin’s Sereebo process, which features chopped carbon fiber combined with nylon using compression molding. Given this, it is likely the GMC bed is made via Sereebo. The application marks a significant and noteworthy advancement in the application of composites in high-volume automotive manufacturing.

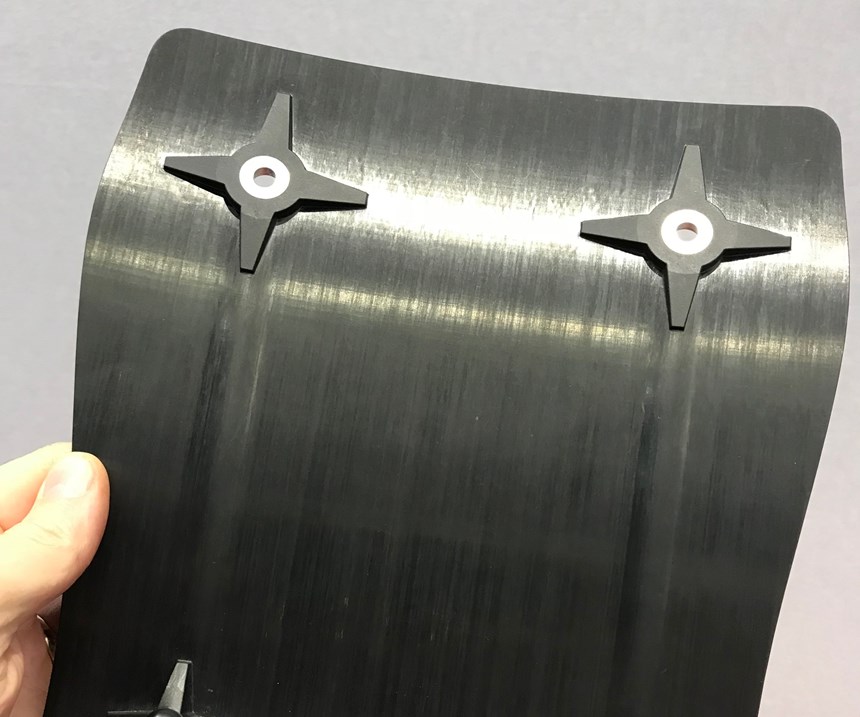

SABIC, Airborne International (The Hague, The Netherlands) and Siemens PLM Software (Waltham, MA, US) revealed that they have worked together to develop a preconsolidated carbon fiber/polycarbonate laminate product called UDMAX. It’s made in a fully automated process developed by Airborne that orients pre-cut unidirectional carbon fiber tapes in 0° or 90° orientations using plies dropped into conveyorized trays, which pass under drop zones as frequently as desired to build the ply stack. The manufacturing system at Airborne, controlled by Siemens, is expected to go live in early 2019. SABIC will sell laminates.

Huntsman Advanced Materials reported at JEC 2018 that it has acquired nanomaterials specialist Nanocomp, based in New Hampshire, US. Nanocomp is best know for its Miralon sheet and tape products, fabricated with nonwoven carbon fiber nanotubes. Sheets can be up to 8 ft long and 54 inches wide, and can be slit. Tapes can be up to 1000 ft long. Miralon offers a ver low CTE, high conductivity, high in-plane thermal conductivity and low through-plane themal conductivity.

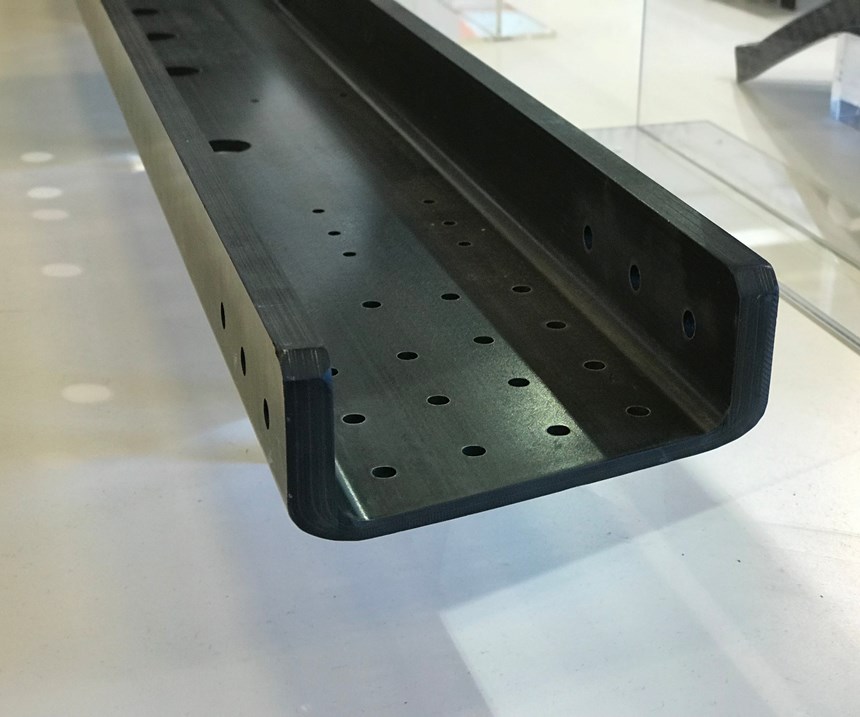

Solvay Composite Materials (Alpharetta, GA, US) had on its stand a trial carbon fiber/epoxy floor beam developed for the 777X using material it developed. CYCOM EP2150 prepreg will be used by a Mubadala Development Co./Solvay joint venture to fabricate 777X empennage and floor beams. This part and project are notable because Solvay developed CYCOM EP2150 as a functional equivalent of the Toray 3900 prepreg that The Boeing Co. (Chicago, IL, US) is using to fabricate the wing skins, wing spar, ribs and wing box for the 777X. Carbon fiber prepregs are, typically, developed to have unique properties, thus it required some effort and time for Solvay to create its own prepreg that so closely matched Toray’s. This would appear to signal to Boeing and rival Airbus (Toulouse, France) that it is possible, on next-generation commercial aircraft, to have multiple carbon fiber suppliers produce prepreg to a given specification. It remains to be seen, however, if the aircraft OEMs pursue this strategy.

Epoxy specialist Hexion (Columbus, OH, US) reported that it has signed an agreement with Kangde Composites Co. Ltd. (Langfang, China) to develop high-volume carbon fiber production methods for automotive composites manufacturing. Kangde is a composites fabricator with expertise in automation. It has production facilities in China and a research center in Wayarn, Germany. Hexion also reported that its epoxy (EPIKOTE Resin TRAC 06170) is being used by the French FastRTM consortium in the development of the compression resin transfer molding (C-RTM) process. Cycle times for the process are said to be 15-60 seconds.

Hexcel (Stamford, CT, US) introduced a new range of HiFlow advanced liquid resins for aerospace structures. The resin family will be designed for use with Hexcel’s HiTape and HiMax dry carbon fiber reinforcements. For wind blades, Hexcel introduced Polyspeed pultruded polyurethane laminates for load-bearing structures, such as spar caps. The company also launched HexPlay XF2P, its surface finishing prepreg for wind blades, which provides a tough, durable, ready-to-paint blade surface without use of a gel coat.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)