Tackling the aerospace supplier’s dilemma: Scalability

Automation and robotics can go a long way toward increasing capacity and growing a business dedicated to aerospace manufacturing. But Trinity Precision has learned that refining the indirect and unseen aspects of its operations can be just as valuable.

As commercial aviation expands to accommodate a new class of international travelers from emerging markets such as China and India, demand on small and midsized aerospace suppliers to expand production capacity is placing a premium not just on automation or skilled labor, but on the supplier’s overall scalability.

The challenge of accommodating for growth and increasing throughput is different today than it was just a few years ago. With a shrinking supply of skilled manufacturing workers responsible for increasingly automated and complex machining processes, scaling up now favors knowledge sharing and the systemization of operations over the traditional goal of simply boosting employee headcount.

This became clear during a recent visit to Trinity Precision, a Wichita, Kan., U.S.-based supplier of machined parts and assemblies for major aerospace companies and defense firms, such as Boeing (Chicago, Ill., U.S.), Textron Aviation (Wichita, Kan., U.S.), Spirit AeroSystems (Wichita), Northrop Grumman (Falls Church, Va., U.S.) and Gulfstream (Savannah, Ga., U.S.). David May, Trinity’s president and co-founder, purchased the shop five years ago when it operated primarily using three-axis vertical mills. May had recently worked at another facility that had undergone a transformation from vertical to horizontal machining centers (HMCs) with palletized equipment, including Makino (Mason, Ohio, U.S.) and Mazak (Florence, Ky., U.S.) cell systems. After purchasing Trinity, he and his team followed suit and began to invest in robotic and palletized HMCs, including a Makino A61 five-axis HMC with its multi-mission compatible (MMC) vehicle system. The purchase was a big win for the company, allowing it to standardize tooling and workholding approaches, add instant capacity by simplifying setups, and run the parts as much as 60 percent faster than on the verticals.

But to say that the A61 cells were the only investment toward scalability that May and his team at Trinity have made in the last five years would undercut at least two impressive aspects of their story — a story that involves robotics and automation, but at its core is about eliminating tribal knowledge in favor of shared and instant access to information.

It’s a story that started with a thorough cleaning.

Whack-a-Mole

When I visited Trinity Precision this past February, May and his team emphasized one key point at the outset: The shop that they’d taken over was, to put it gently, a mess. The walls were covered in grime. Tools and raw materials were scattered throughout the shop. An open coolant barrel sat underneath a circuit breaker box. File cabinets contained the old company’s paper folder system it still used for work orders. May’s team calculated that each shopfloor employee had to travel more than 3,000 feet per work order per setup just to collect the necessary parts and tools. Assembly operations took place on plastic folding tables.

On the first day after taking over operations, May shut down the business for 72 hours to clean the facility. The team, which included several employees who stayed after he took over, filled a dozen 20-foot-long dumpsters with trash.

But in many ways the near-gutting of the shop provided an opportunity to start from scratch. And the investment in the A61 cell and pallet system certainly was a significant leap forward. In less than a year, the team standardized tooling and workholding approaches in a manner that allowed them to program nearly 350 unique part numbers using fewer than 20 unique workholding components. Today, the number of parts running on the A61 has increased to 800.

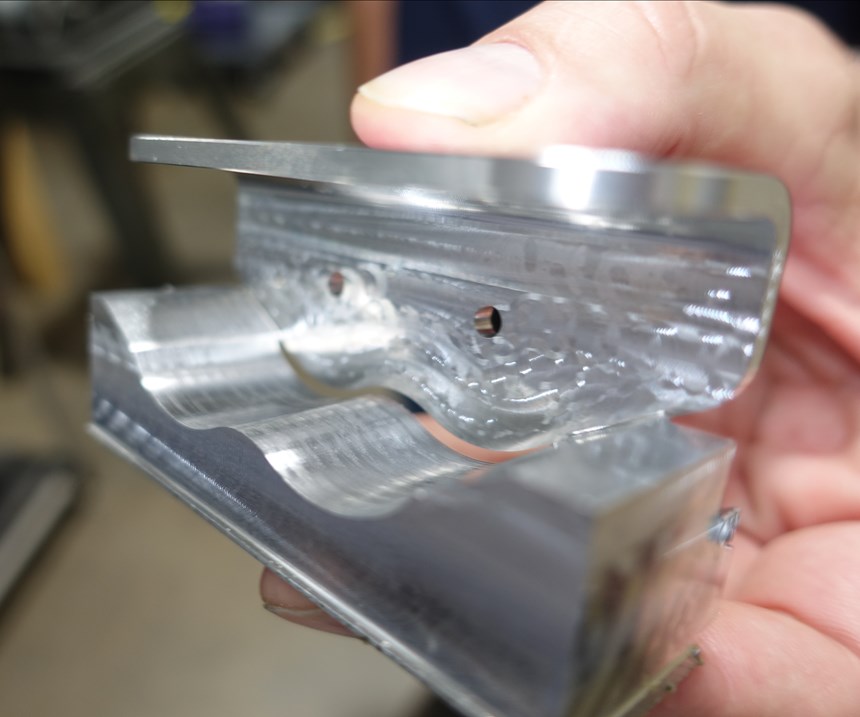

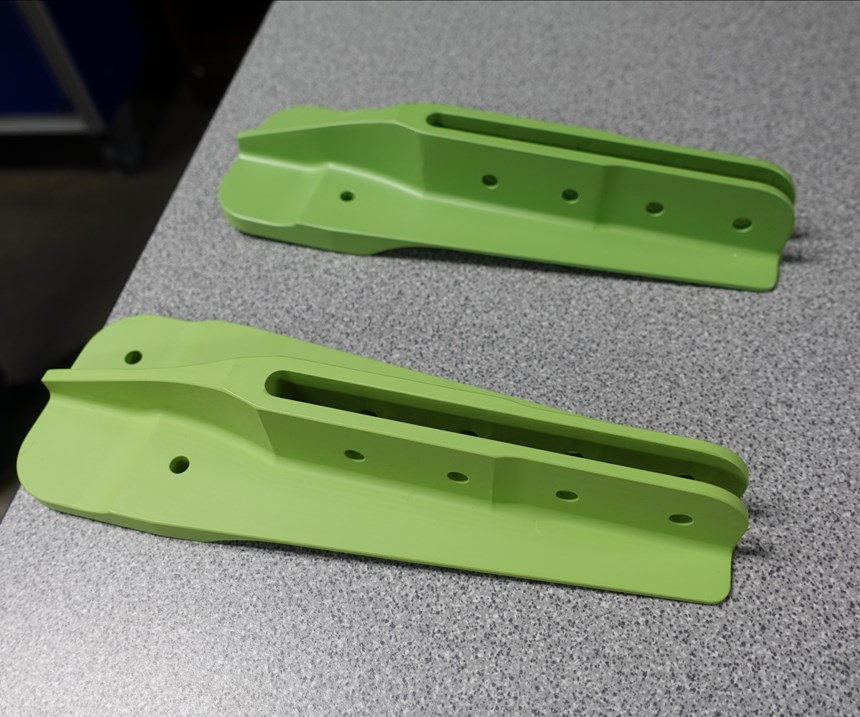

In 2016, Trinity added a FANUC (Rochester Hills, Mich., U.S.) Robodrill machining center that allows the company to run high-mix, low-volume jobs with the aid of a five-axis robotic arm. While there was room to increase the capacity for the A61 cell, many of Trinity’s parts begin with similar workpieces that take a considerable amount of time to load and unload. The Robodrill enables the workpieces to be staged in a row and loaded automatically — in less than 12 seconds each — for a two-stage milling operation. It machines a dovetail profile into one side of the workpiece blank, the robotic arm flips the piece over, and a second vise jaw takes hold of the newly machined dovetail — a workholding solution that exposes nearly all of the workpiece to the next machining operation that completes the part. In the meantime, the first jaw takes hold of a new workpiece.

When the cycle is complete, all that is left holding the dovetail to the finished part are two small tabs. The machine operator then takes a large rubber mallet and, Whack-a-Mole style, knocks the part loose from the tabs, leaving only two small burrs to be removed.

Chris VanNover, Trinity’s co-founder and vice president of operations, says that after the company hired programmers to create the initial programming code for the Robodrill, operators now can teach the robot new operations without having to write new code. “Now we can hand-walk the robotic arm through a new program step by step to find a new position, move it, reteach that position, change it for the raw material, reteach that position again, then save that as a unique program,” he says. “With very small modifications, we can take an existing program, make a couple modifications, copy it and save it as a different program number.”

In a way, this manual method of programming is one example of democratizing information for the greater good at Trinity. But when the company began to integrate cross-departmental data into its material requirements planning (MRP) system, it took this concept much further.

Tribal counsel

Some shops can get by with an organizational structure in which only a small number of employees have access to key pieces of information. This information could be data from machine monitoring analytics, materials procurement, shipping and receiving, production schedules or any number of business operations. When this information is localized within a single department, or even a small number of employees within that department, those employees serve as gatekeepers of that information. If Bob in your shipping department isn’t around to tell you when the next shipment of material is scheduled to arrive, tough luck! Your customers will have to wait until Bob is back before you can tell them when their parts will be delivered.

Contrast that with this fact: Trinity’s home of Wichita is one of the nation’s largest aerospace manufacturing hubs. To spotlight what this means for companies like Trinity that want to scale-up their businesses, consider that the day before visiting Trinity I visited the vast headquarters of Spirit AeroSystems, the world’s largest aerostructures manufacturer, and briefly met the head of Spirit’s HR department. She excitedly told us that the company was pushing forward with plans to hire 1,400 new employees over the next year—in addition to the 1,000 it hired last year. For Trinity, this means that growing its business necessarily includes strategies and tactics well beyond increasing employee headcount. And key among those strategies is streamlining and sharing information across processes and departments.

To jumpstart that goal, the company hired a business systems manager, Jason Hansen, to integrate information flows from multiple departments into its MRP system. The result is a sort of master data hub that all departments rely on for information related to production, shipping, materials and more.

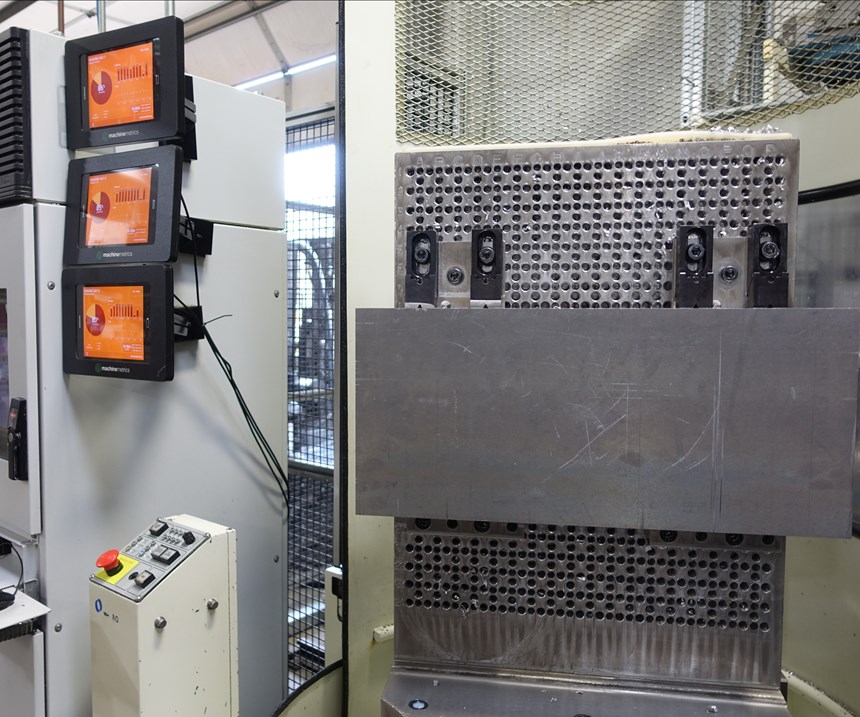

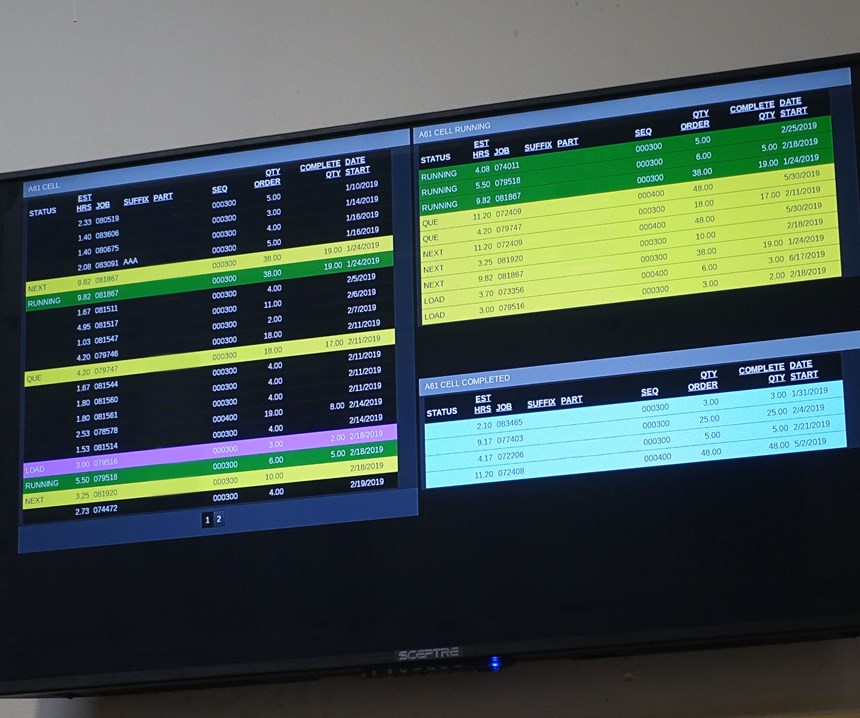

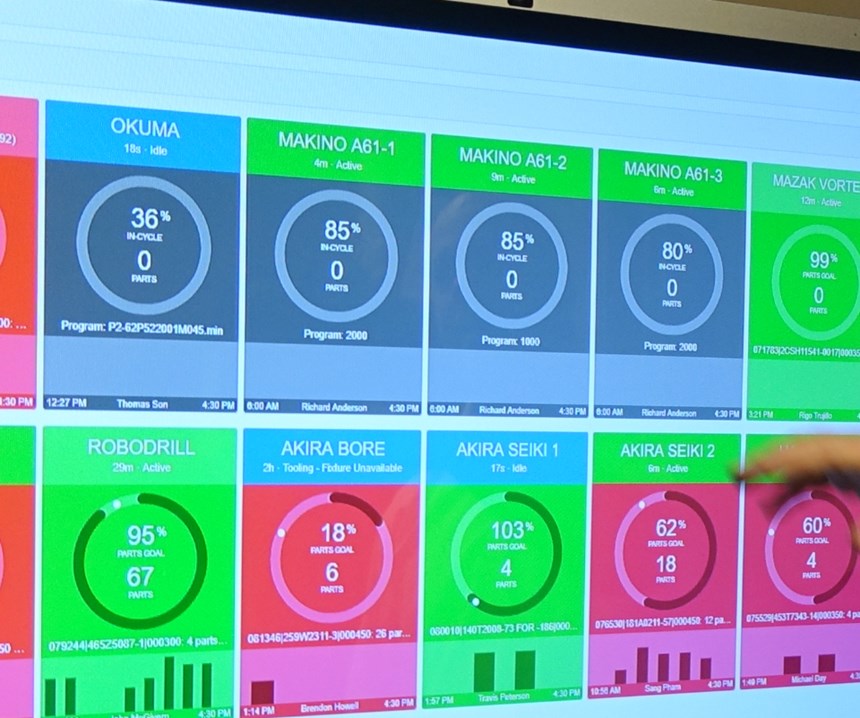

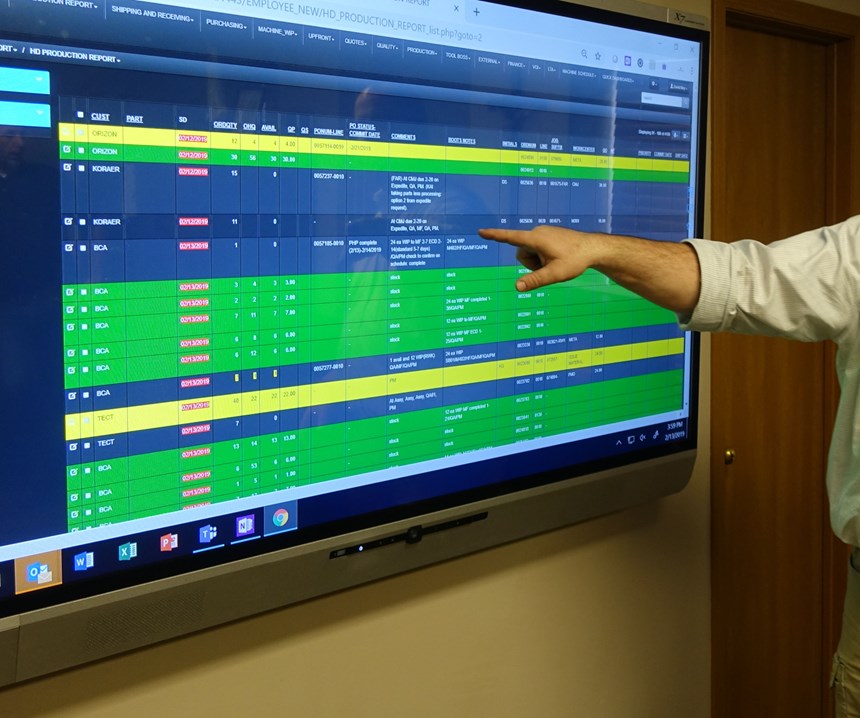

For instance, Trinity uses Machine Metrics software as its machine monitoring platform. Hansen has integrated the Machine Metrics data into Trinity’s global MRP system to track information such as machine clocking, utilization, spindle engagement and operator loading. Installed throughout the plant floor are large-screen monitors that display live data from the MRP from machining centers throughout the shop. As Chris VanNover points out, this information delivers ownership of production to the operators. “Why? Because now they can see, number one, what's expected of them,” he says, “and number two, they can look up at the screen and realize, ‘Oh no, I'm in the red!’ But now they’re empowered to say, ‘If I can flip two of these red cells to green, boom, we can get back on schedule.’”

Just as importantly, these data are linked directly to related processes from each job’s original quote, such as material tracking and shipping. All of this information can be accessed in the production queue of the MRP system. For instance, an operator can open the queue to see a prioritized list of jobs that are scheduled to run on any given work center. With one click, that operator can check the material availability for those jobs as well as whether that material might be needed for higher priority jobs. “It helps us to avoid robbing Peter to pay Paul,” Hansen says. He points to the onscreen display at a job scheduled to run on a Haas VMC that needs 10 workpieces. “It needs 10, but we have eight in stock that can be allocated to it,” he says. “So he knows right away: if we need 10 but only have eight, does it make sense to reduce it and run the eight?” To answer that question, Hansen says, the operator just clicks on the material tab to see when the next order is scheduled for delivery. There is no legwork involved, and the system tells him right away when he can get those parts out.

Sound vision

One of the chief reasons that a major aerospace company like Boeing might reject a part or assembly from a supplier is part misidentification. Some of the parts that Trinity manufactures contain geometries that are nearly identical to others, which is a problem that might not become apparent until far down the assembly line when the part does not mate to its designated location. The potential for wasted time and money is great, not to mention the potential hazard created if a faulty part finds its way onto an aircraft.

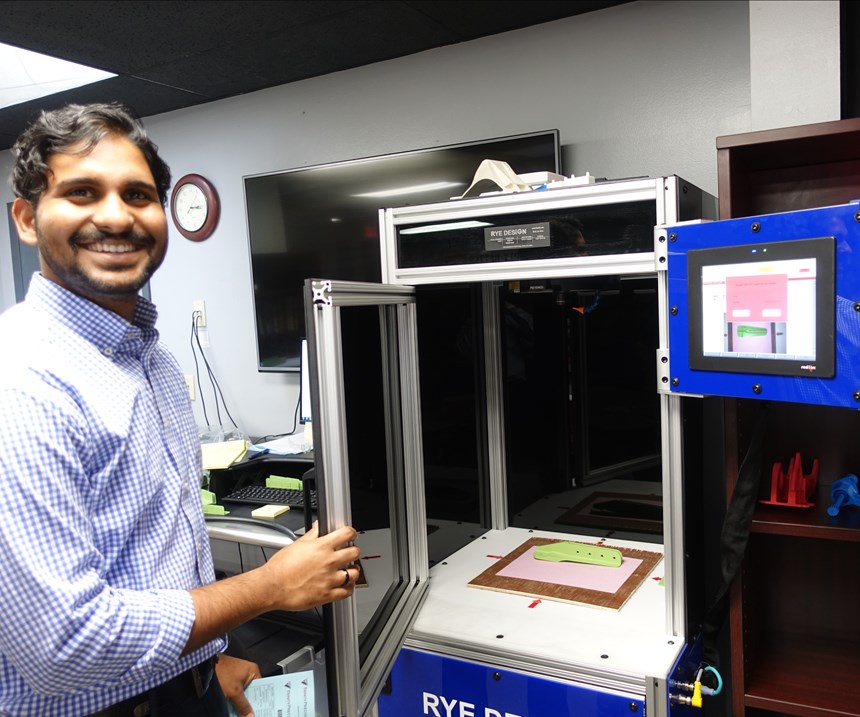

Misidentified parts have been a cause of concern for Trinity typically when they are returned from outside operations back to Trinity for assembly. In the past, the company employed an inspector who measured the nuanced features of each part to confirm its identity — a painstakingly slow and tedious process. Just two weeks before my visit, Trinity had brought onboard an automation engineer named Joel Koripalli to find a better solution.

Trinity worked with Oklahoma-based custom automation provider Rye Design to create a system that uses Keyence (Itasca, Ill., U.S.) vision technologies and a software interface that Koripalli is programming and refining. After just two weeks on the job, he had already programmed dozens of the hundreds of parts that the system will eventually inspect. The finished process is simple: Scan the barcode of the part number, place the part face-up into a mini-fridge-sized box and push a button to engage the vision system. If the key features of the original part (based on a previous scan of the part, and not a CAD model) are identical to those of the part being scanned, an indicator light turns green. If the features do not match, the light turns red. This saves substantial time while greatly improving accuracy over the manual process.

From robotics and automation to inspection and data sharing, the systemization of processes at Trinity touches nearly every aspect of its operations. When May and his team realized that their customer service representatives were constantly tracking down team members from the shipping department to ask whether parts had been packed or delivered, they calculated the costs related to the shipping department having to stop and look up the part number in its system. Trinity team members tackled the problem first by adjusting the physical layout of the shipping department and designating aisles for different part families. They also automated data entry processes tied to shipping, so when an employee scans a packing slip, that information is instantly available to customer service representatives (and others) through the MRP system. Even the printers within the shipping department are kept separate according to different part families.

All of these aspects of Trinity’s core business operations represent potential costs and lost time when uncertainty about any given process creeps in. The tangible benefits for efficiencies in machining operations might be easier to identify, but the indirect and unseen aspects of business operations need to be analyzed and refined, too. This is at the core of what May and his team — now up to 73 employees — are doing. In five years, they’ve tripled the shop’s revenue to $18 million, and aim to hit $50 million within the next five.

“Businesses that aren't developing a way to automate both the manufacturing process and transactional data will be in serious trouble trying to find people,” May says. “There's a strategic imperative. The more that we can automate the mundane, the transactional, the more we elevate our current workforce to employ higher-level skills that bring value to them and their families.”

Related Content

Women in the Composites Industry brings together women for networking, educational opportunities

Aiming to support the growth of women in this industry, the WCI industry group and its partners recently held its first live training event hosted by Owens Corning.

Read MoreComposites UK launches best practice guide for composites tooling

“Mould Tooling for Fibre-Reinforced Polymer Composites” is latest in Composites UK’s series of good practice guides, available online for free.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreBelzona opens fifth European SuperWrap Training Centre

Global training facilities provide intensive, first-class installer and supervisor training for proper use and application of Belzona composite pipe and tank repair systems.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More