CRG (Cornerstone Research Group Inc.)

2750 Indian Ripple Rd.

Dayton, OH 45440 US

937-320-1877

info@crgrp.com

crgrp.com

About CRG (Cornerstone Research Group Inc.)

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

CRG (Cornerstone Research Group Inc.) Supplies the Following Products

- Acrylic, Film

- Acrylic, Solvent-based

- Aerospace, aircraft interior

- Aerospace, flight control surfaces

- Aerospace, fuselage/wing

- Armor, composite

- Autoclave cure

- Automated fiber placement

- Automotive, body panels & substructures

- Automotive, interior (seats, IPCs, floor panels, etc.)

- Bismaleimide (BMI)

- CAD/CAM/CAE design

- Chromatography

- Civil engineering

- Compression molding

- Consulting, materials

- Consulting, process development

- Consulting, structural design

- Continuous laminating

- Cure-monitoring equipment

- Custom compounding and blending

- Cutting, finishing, and machining

- Cyanate ester

- Environmental testing equipment

- Epoxy

- Epoxy, 250 F cure

- Epoxy, 350 F cure

- Epoxy, Film

- Epoxy, Solvent-based

- Epoxy, toughened

- Fatigue-testing equipment

- Filament winding

- Finite element modeling/analysis (FEM/FEA)

- Flame/smoke toxicity testing

- Flammability/smoke testers

- Flexible mold materials

- Flexural testers

- Hand layup

- Infrastructure, composite

- Injection molding

- Laminate panels, with core

- Laminate sheets, solid

- Mandrels, inflatable

- Mandrels, other

- Marine, boat (hulls, decks, bulkheads, etc.)

- Materials analysis

- Mechanical test fixtures

- Modeling/simulation/virtual testing software

- Modulus testers

- Moldmaking and patternmaking

- Other casting resins

- Other composite structures

- Other fabricating services

- Other matrix materials

- Other services

- Other testing equipment

- Other thermoplastics

- Other thermoplastics fabricating services

- Other thermoset fabricating services

- Other thermosets

- Other tools/tooling supplies

- Other, Other

- Polyimide

- Product design

- Prototyping

- Repair kits and equipment

- Resin content analyzers

- Resin transfer molding (RTM)

- Rotational molding

- Structural health monitoring equipment (turnkey systems

- Structural strengthening / reinforcement services

- Surface treatment

- Syntactic core

- Tensile testers

- Testing, materials

- Textile processing for composites (braiding, stitching, weaving)

- Thermal analysis instruments

- Thickness measuring equipment

- Tubes

- Universal test frames

- Vacuum-assisted resin transfer molding (VARTM)

Editorial, News, and Products

-

Hawthorn Composites awarded structural inlet duct manufacturing contract

Manufacture of inlet ducts for Kratos unmanned combat aerial vehicle involves an automated dry fiber overbraiding process, VARTM infusion and oven cure.

-

AFRL evaluates braiding, SMP tooling and VARTM for lower-cost future engine inlet ducts

U.S. Air Force and Ohio-based composites team develop new process for S-shaped aerostructure.

-

Cost-effective aerocomposites: Dry fiber AFP and resin infusion

Aurora Flight Sciences and NONA Composites aim to improve toughness, repeatable aerospace quality and affordability for large-scale NASA structures.

-

CW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

-

New low-cost, high-temp resins

MG Resins offer a suite of properties and processing that could potentially revolutionize sectors of the composites industry.

-

CFRP camera boom enables safe spill inspection

NONA Composites’ 32m REACH structure meets tight remediation schedule at DoE radioactive waste storage site.

-

Composite tooling without oven or autoclave

No Oven No Autoclave technology has been demonstrated in tooling for NASA, including multiple thermal cycles and use for curing epoxy infused out-of-autoclave parts.

-

CAMX 2014 exhibit previews, part 2

With CAMX 2014 less than a week away (Oct. 13-16, Orlando, Fla.), CompositesWorld offers a final glimpse of some of the products, technologies and services that you will find in booths in the Exhibit Hall. During the show, we'll keep you informed and up-to-date with the CAMX Show Daily, which will be distributed Tuesday, Wednesday and Thursday at the show. Safe travels to Orlando and we look forward to seeing you at the conference and trade show.

-

No-oven, No-autoclave (NONA)

Room-temperature cure epoxy composites with a 400°F Tg, comparable properties vs. commercial systems without external heat or post-cure, and offering reduced cost and cycle time. Really?

-

SAMPE 2013 Long Beach new product showcase

The SAMPE 2013 trade show (May 6-9, in Long Beach, Calif.) was the venue for introductions of a large number of new composite materials, technologies and manufacturing processes. Here's the HPC editorial staff's compilation of what was on display.

-

SMPs: Reshaping old realities

Moving quickly from science fiction to science fact, shape-memory polymer composites show great potential in aerospace applications.

-

SAMPE 2010 Seattle Showcase

SAMPE’s first-ever foray into Boeing Country wrapped up with the M&P organization’s biggest draw this decade.

-

Composites 2010 Product Showcase

The ACMA’s Las Vegas exhibition reflected an industry in recovery.

-

SAMPE 2009 Product Showcase

Showgoers at the SAMPE 2009 Conference and Exhibiton in Baltimore, Md. found many suppliers undeterred by poor economic news.

-

In-situ composite repair builds on basics

For on-aircraft repair, demand is on the rise for specialized composites training and expertise.

-

Composites enable micro air vehicle

Real-time sensing capability makes slow-flight VTOL MAV a "man replacement."

-

Structural health monitoring: Composites get smart

New initiatives are mainstreaming real-time monitoring systems into composites on aircraft, wind blades and other critical performance structures.

-

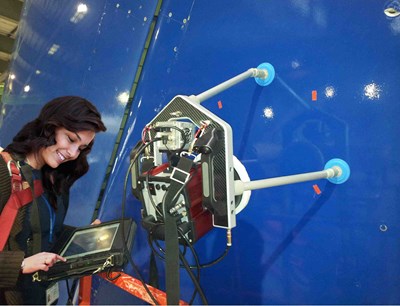

Self-healing Composite Prototyped for NASA

At the recent SAMPE Conference and Exhibition (see “Related Content,” at left) Cornerstone Research Group’s (CRG, Dayton, Ohio) Reflexive composites were touted as a composite system that, according to CRG’s research and development engineer Thomas Margraf and chief engineer Ernie Havens, can detect and heal damage in

-

The changing shape of future aircraft

"Morphing" is no longer just for the birds.